A slewing bearing, also known as a slewing ring or turntable bearing, is a rotational rolling-element bearing that typically supports a heavy but slow-turning or slow-oscillating load. Slewing bearings are large-sized bearings specifically designed to accommodate axial, radial, and moment loads simultaneously. They incorporate an inner and outer ring, which can be bolted to other structures, such as a rotating platform or a static base.

Flanged Four Contact Ball Slewing Bearing

Flange type slewing bearing also belongs to four-point contact ball slewing bearing.

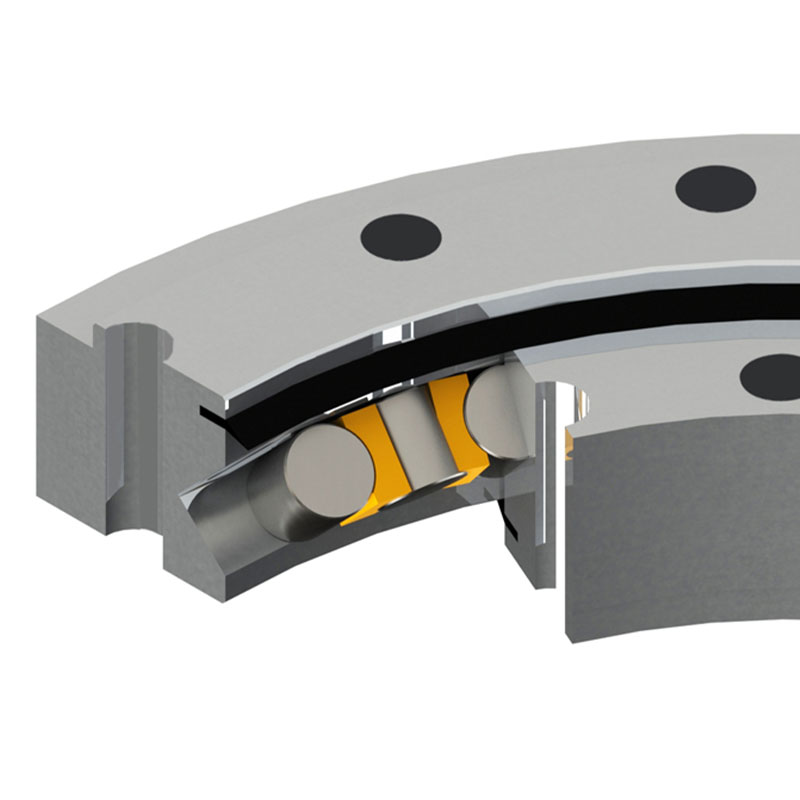

Read More Get A QuoteCrossed Cylindrical Roller Slewing Bearing

The cross roller slewing bearing is mainly composed of an inner ring, an outer ring, rollers,

Read More Get A QuoteExcavator Travel Reduction Bearings

Excavator travel reducer bearings are also called side reducer bearings or tooth box bearings.

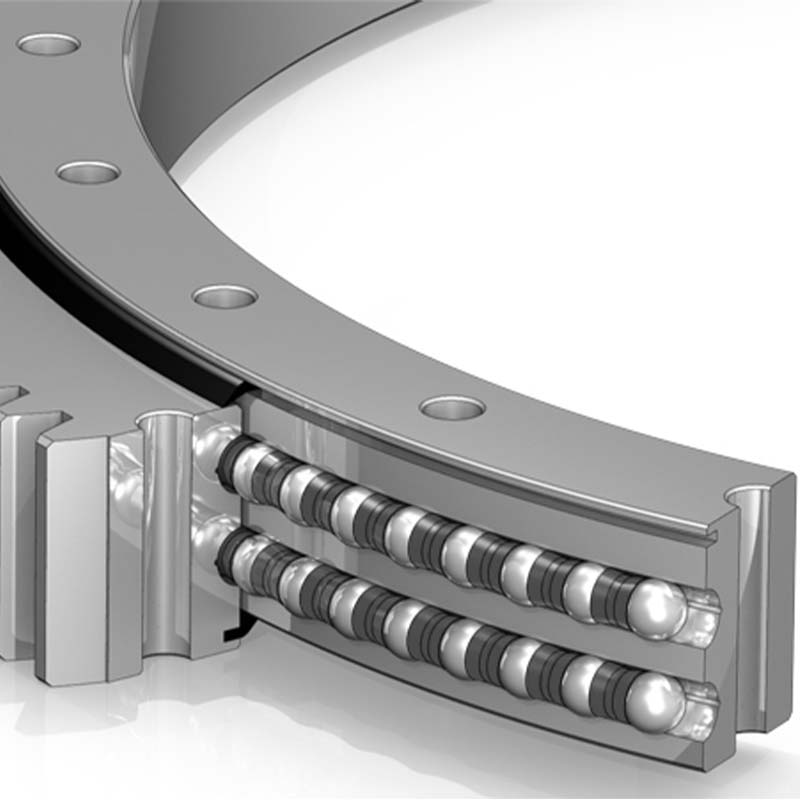

Read More Get A QuoteDouble Row 8 Point Contact Ball Slew Bearings

The double-row ball slewing bearing is mainly composed of an inner ring, an outer ring, two rows of rolling elements (steel balls), a spacer or a cage and a sealing device.

Read More Get A QuoteTruck Crane Slewing Bearing

Professional slewing bearing for truck crane, reliable supplier with high quality product Customize

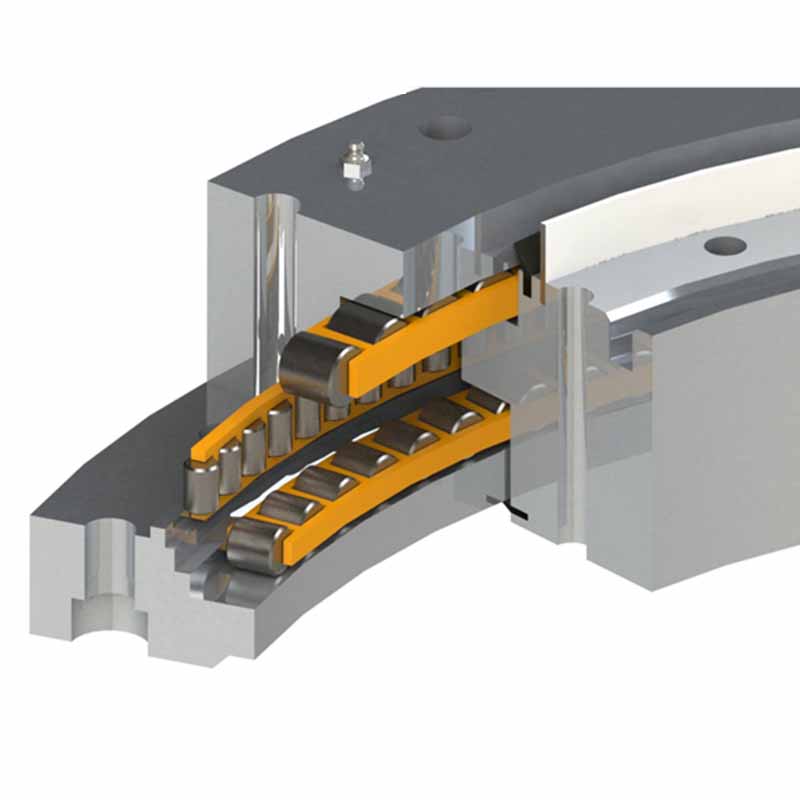

Read More Get A QuoteThree Row Roller Slewing Bearing

The three-row roller slewing bearing consists of an inner ring, an outer ring, three rows of rollers

Read More Get A QuoteExcavator Slewing Bearing

The excavator slewing bearing is a force transmission element for the upper and lower bodies to make

Read More Get A Quote

Features of Slewing Bearings

High Load Capacity: Slewing bearings are designed to handle combinations of large axial, radial, and moment loads.

Compact Design: Despite their load-bearing capabilities, slewing bearings have a compact form factor, which is crucial for applications where space is limited.

360-degree Rotation: They facilitate smooth and continuous rotation in one plane, making them ideal for applications requiring full rotation.

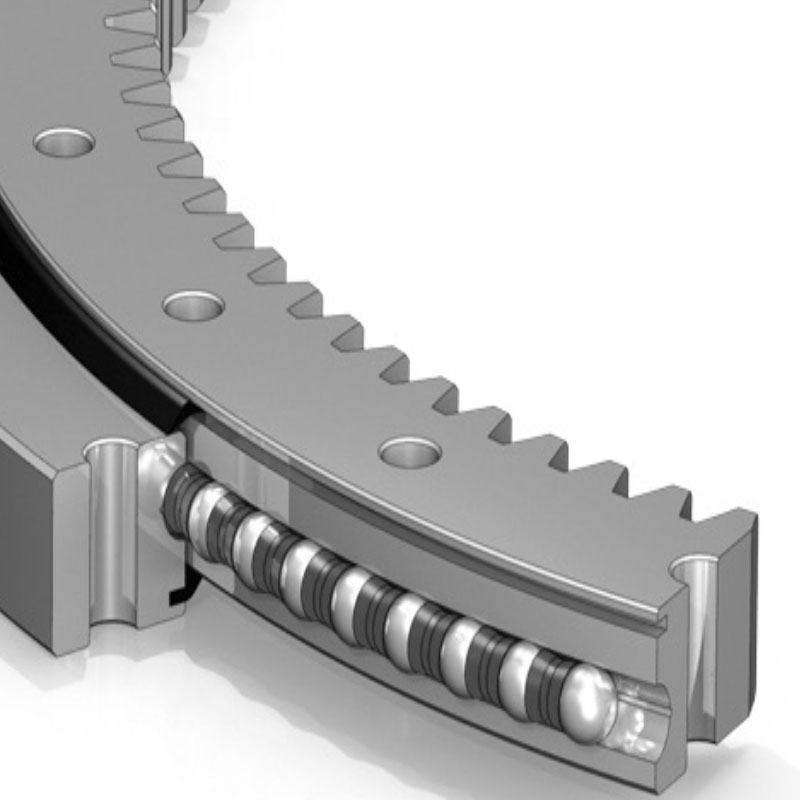

Integration of Gears: Many slewing bearings have integral gears on either the inner or outer ring, which allows for the integration of driving mechanisms.

Customizability: They can be customized with different materials, seal types, and gear configurations to suit specific applications and environments.

Types of Slewing Bearings

Single-row Ball Type: Features a single row of balls and can support axial, radial, and moment loads. Suitable for light to medium load applications.

Double-row Ball Type: Has two rows of balls, which allows for greater load capacity and better stability. Ideal for applications with higher radial load requirements.

Crossed Roller Type: Rollers are arranged in a crossed pattern, which increases the bearing's ability to withstand higher moment loads and provides greater precision and stiffness.

Three-row Roller Type: This type includes three rows of rollers that handle different load directions separately, thus offering the highest load capacity among slewing bearings.

Applications of Slewing Bearings

Cranes and Lifts: Used in the rotating bases and booms of tower cranes, mobile cranes, and aerial lifts.

Wind Turbines: Facilitate the rotation of the nacelle and the adjustment of the blades.

Medical Equipment: Employed in the rotating parts of advanced medical machines like CT scanners and dental chairs.

Construction Machinery: Used in excavators and tunnel boring machines for rotation.

Marine Equipment: Integral to the operation of shipboard cranes, gangways, and radar masts.

Robotic Arms: Provides rotational movement in industrial automation systems.

How to Lubricate Slewing Bearings?

Proper lubrication is crucial for the performance and longevity of slewing bearings. Here’s how to lubricate them effectively:

Choose the Right Lubricant: Use a grease or oil recommended by the bearing manufacturer, which is suitable for the specific load, speed, and environmental conditions.

Lubrication Points: Apply lubricant to the gears and the rolling elements through the grease fittings. Ensure that the entire raceway is covered.

Frequency: The frequency of lubrication depends on the operating conditions. Regularly check the lubrication state and follow the manufacturer's guidelines—typically, re-lubrication is recommended after every 100 hours of operation or monthly, whichever comes first.

Clean Application: Ensure that the areas around the lubrication points are clean to avoid introducing contaminants into the bearings.

Regular inspection and maintenance, including lubrication, are essential to maximize the lifespan and efficiency of slewing bearings, especially given their critical role in heavy machinery and large-scale applications.