The S series slew drive is specifically designed for applications that require reliable and efficient rotational motion but do not demand the heavy-duty specifications of more complex systems like the SE or WE series. The "S" in S slew drive typically stands for "standard," highlighting its role in standard applications where moderate precision and load capacity are sufficient.

Open Housing Slew Drive S14

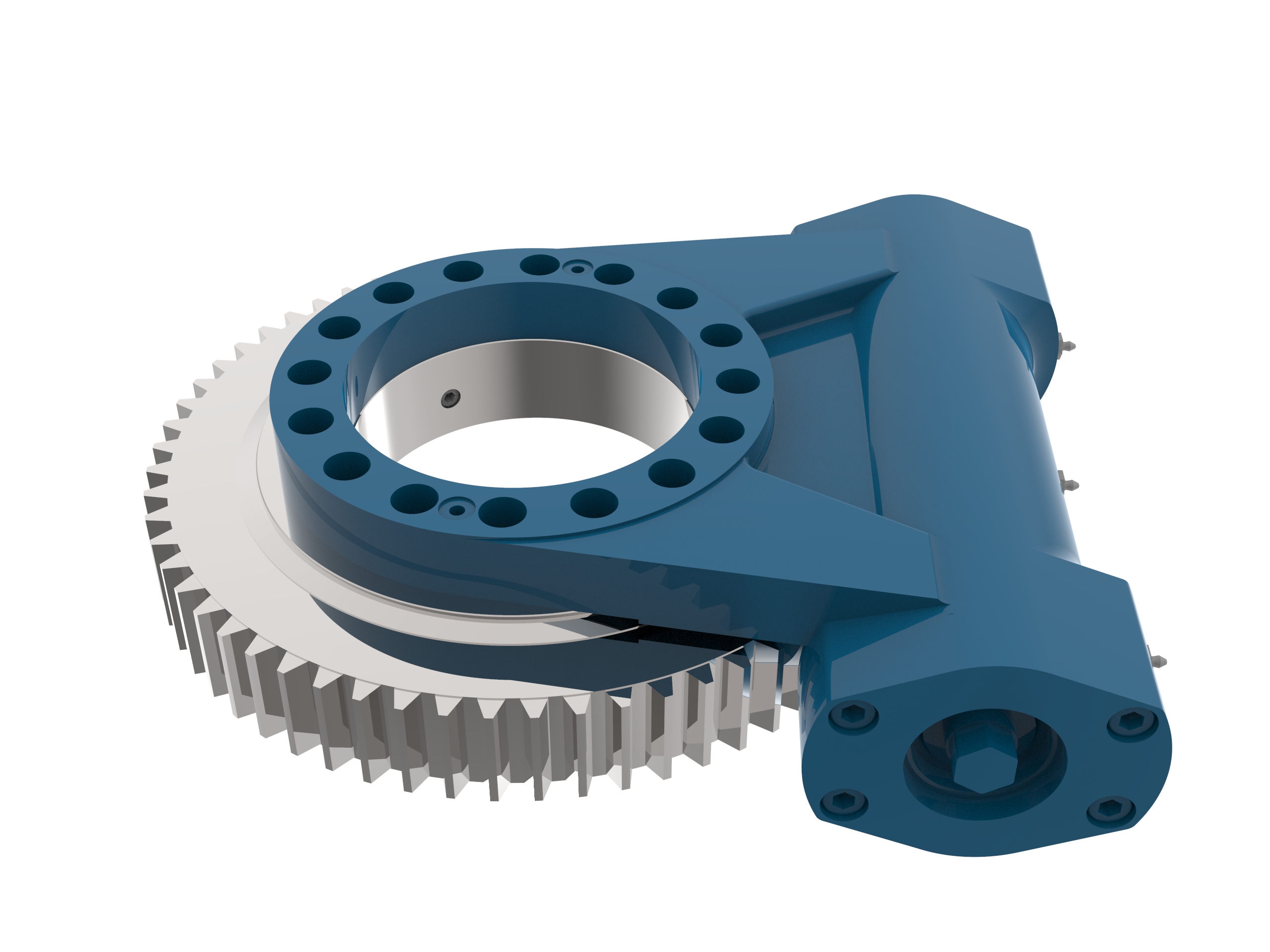

Open Housing Slew Drive S14 is an advanced integrated modular transmission component designed to facilitate efficient rotary motion across various applications.

Read More Get A QuoteOpen Housing Slew Drive S17

The Open Housing Slew Drive S17 is a versatile and lightweight integrated transmission component designed for high-performance rotary applications, featuring self-locking functionality and enhanced torque capacity, making it ideal for use in aerial work platforms, mobile cranes, and industrial machinery, with ordering facilitated through Lyra Drive, a trusted manufacturer.

Read More Get A QuoteOpen Housing Slew Drive S19

The Open Housing Slew Drive S19 is a lightweight, reliable rotary drive designed for various applications, featuring a self-locking mechanism, enhanced torque capabilities, and built for efficiency in industries like construction and mobile cranes.

Read More Get A QuoteOpen Housing Slew Drive S9

The Open Housing Slew Drive S9 is a lightweight, high-performance rotary drive designed for applications like aerial work platforms and cranes, featuring self-locking capabilities and enhanced torque handling, making it a reliable choice for various industrial uses.

Read More Get A Quote

What is an S Slew Drive?

An S slew drive incorporates a slewing ring bearing and a worm gear, packaged in a simpler and often more compact design compared to more robust models. This design provides good performance in terms of torque transmission and load-bearing, making it suitable for a variety of moderate applications.

Key Features of S Slew Drives

Simplified Design: The S slew drive is less complex than its heavier-duty counterparts, making it easier to produce and maintain. This simplicity also leads to a reduction in potential points of failure.

Cost-Effectiveness: Due to its straightforward manufacturing process and fewer materials used, the S slew drive is generally more affordable than more specialized slew drives.

Moderate Load Handling: While not designed for extremely high loads, the S slew drive can handle moderate axial, radial, and moment loads effectively.

Versatility: This type of slew drive can be adapted to a wide range of applications that require standard performance without the need for extreme specifications.

Ease of Installation: The compact and less complex nature of the S slew drive makes it easier to install and integrate into various systems.

Applications of S Slew Drives

The S slew drive is utilized across various sectors, particularly where the demands do not justify a more heavy-duty system:

Solar Trackers: In smaller or residential solar applications, the S slew drive provides adequate performance for adjusting panels to follow the sun.

Small Cranes and Manlifts: Suitable for light to medium lifting tasks where high precision and load capacities are not critical.

Rotary Tables: Common in light industrial applications, such as assembly stations or small turntables.

Antenna Positioning: Used in communication systems where moderate accuracy and reliability are needed for positioning antennas.

Theatrical and Staging Equipment: Provides motion for stage elements in theatres and during live performances, where smooth and reliable operation is necessary.

Selecting an S Slew Drive

Choosing the right S slew drive involves considering several key factors:

Load Requirements: Assess the maximum expected loads in terms of axial, radial, and moment forces to ensure the slew drive can handle them without over-specifying the system.

Environmental Conditions: Consider whether the drive needs additional protection against dust, water, or other environmental factors based on where it will be installed.

Operational Precision: Determine the required precision and whether the S slew drive's standard capabilities meet these needs.

Space Constraints: Evaluate the installation space to ensure the slew drive will fit without requiring significant modifications to existing structures.

Budget: Since S slew drives are more cost-effective, they are ideal for projects with tighter budget constraints but still require reliable performance.