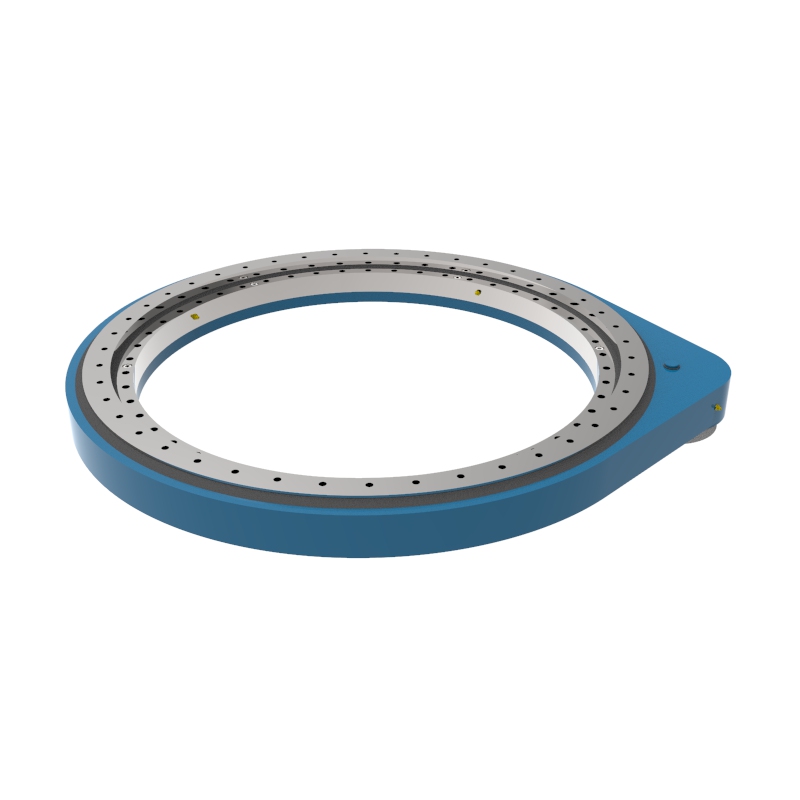

The SP-M Slew Drive typically refers to a slew drive configuration that incorporates multiple rows of rolling elements, such as ball bearings or roller bearings. This design is intended to handle higher load capacities and provide greater stiffness compared to single-row configurations like the SP-I. The "M" in SP-M often stands for "Multi-row," indicating the presence of more than one row of rolling elements.

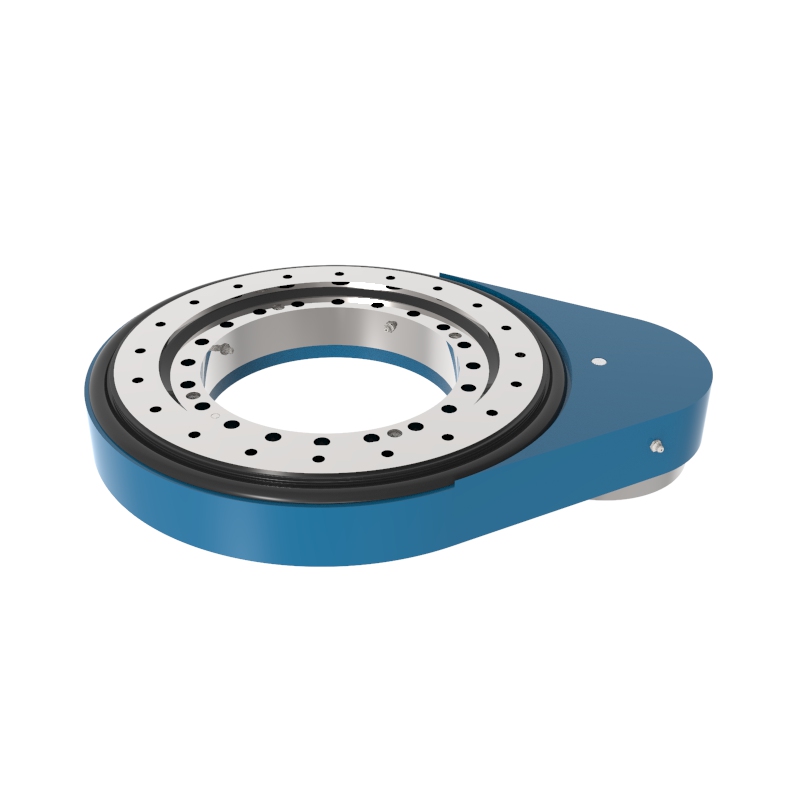

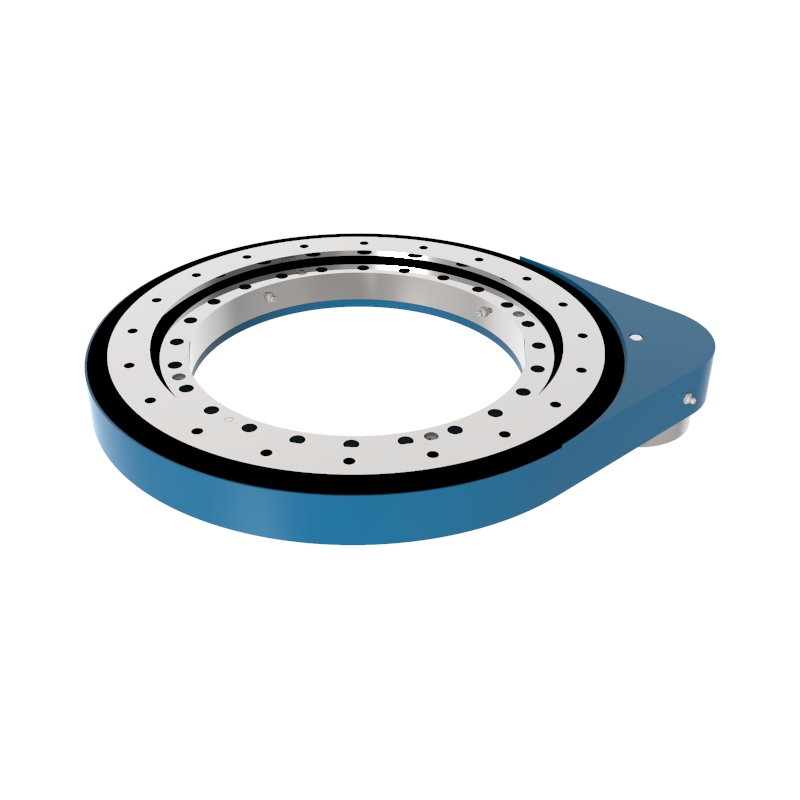

Medium Duty Gear Slewing Drive SP-M 0311

SP-M 0311 gear slewing drive is a highly efficient gear reduction transmission device, which is wide

Read More Get A QuoteMedium Duty Gear Slewing Drive SP-M 0411

SP-M 0411 gear slewing drive is a highly efficient gear reduction transmission device, which is wide

Read More Get A QuoteMedium Duty Gear Slewing Drive SP-M 0541

SP-M 0541 gear slewing drive is a highly efficient gear reduction transmission device, which is wide

Read More Get A QuoteMedium Duty Gear Slewing Drive SP-M 0641

SP-M 0641 gear slewing drive is a highly efficient gear reduction transmission device, which is wide

Read More Get A QuoteMedium Duty Gear Slewing Drive SP-M 0741

SP-M 0741 gear slewing drive is a highly efficient gear reduction transmission device, which is wide

Read More Get A QuoteMedium Duty Gear Slewing Drive SP-M 0841

SP-M 0841 gear slewing drive is an efficient medium-sized gear reduction transmission device, which

Read More Get A QuoteMedium Duty Gear Slewing Drive SP-M 0941

SP-M 0941 gear slewing drive is a highly efficient gear reduction transmission device, which is wid

Read More Get A QuoteMedium Duty Gear Slewing Drive SP-M 1091

SP-M 1091 gear slewing drive is a highly efficient gear reduction transmission device, which is wid

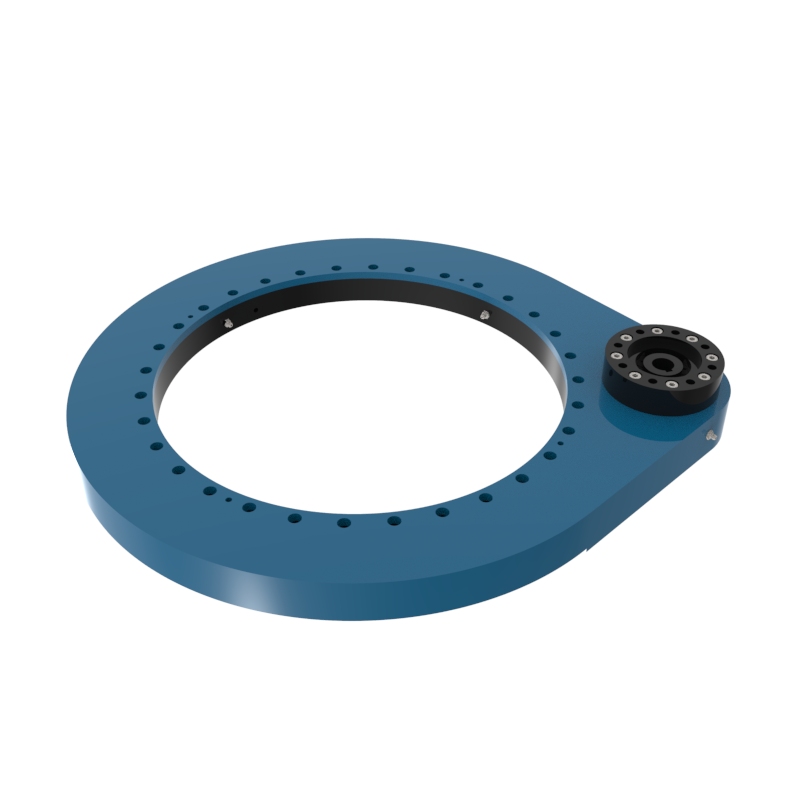

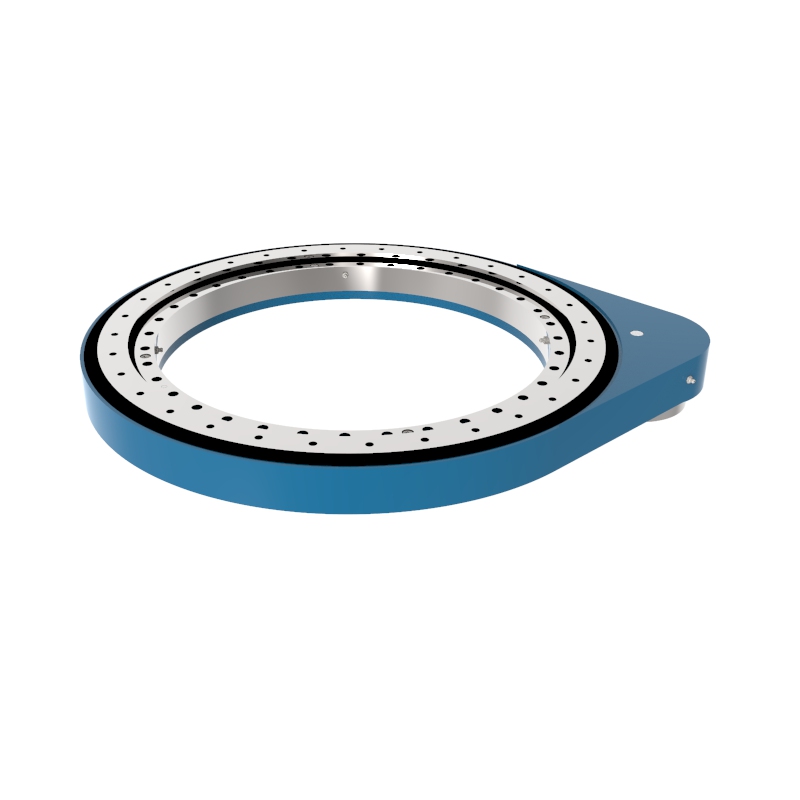

Read More Get A QuoteDesign of SP-M Slew Drive

Multi-Row Bearings: The SP-M slew drive features multiple rows of bearings that can be either ball or roller type. These multiple rows allow the slew drive to support larger loads and provide higher rigidity and stability.

Integrated Gear System: Similar to other slew drives, the SP-M includes an integrated gear system, which can be internal or external. This gearing system is designed to interface directly with a motor, such as an electric or hydraulic motor, to provide the necessary rotational force.

Sealed Housing: The components are typically enclosed within a robust housing that protects the internal mechanisms from dirt, debris, and water ingress, ensuring reliable operation under various environmental conditions.

Features of SP-M Slew Drive

High Load Capacity: The use of multiple bearing rows significantly increases the load capacity, making it suitable for applications involving heavy loads.

Enhanced Stiffness and Stability: Multi-row bearings provide greater system stiffness and stability, which is crucial for applications requiring precise control and alignment.

Versatility: This type of slew drive can be adapted to a wide range of applications due to its robust design.

Durability: The design and materials used in SP-M slew drives are selected to ensure long service life and resistance to wear and tear.

Customization: Many manufacturers offer customizable gear ratios, motor interfaces, and other features to meet specific application requirements.

Typical Applications of SP-M Slew Drive

Heavy-Duty Cranes and Lifting Equipment: Used in the rotation mechanisms of tower cranes, mobile cranes, and boom lifts where handling large loads is required.

Wind Turbines: For yaw and pitch control mechanisms in wind turbines, where the drive needs to support significant forces and operate reliably in harsh conditions.

Marine Cranes and Equipment: In applications such as shipboard cranes, where stability and high load capacity are essential.

Large Antenna Systems: Provides the necessary support and precision for large-scale communication and radar antennas.

Mining Equipment: Used in mining machinery for tasks that require robust and reliable rotational motion handling.

Selection Considerations for SP-M Slew Drive

Load Capacities: It is critical to understand the axial, radial, and moment load capacities required by the application to select the appropriate slew drive configuration.

Environmental Conditions: Consider the operating environment, including temperature, humidity, exposure to corrosive elements, and potential for contamination.

Motor Integration: The slew drive should be compatible with the type of motor used, whether electric, hydraulic, or otherwise. The interface between the motor and the slew drive must be well-coordinated for optimal performance.

Operational Requirements: Define the speed, precision, and rotational torque requirements. These factors will dictate the choice of gear ratios and bearing types.

Maintenance Needs: Choose a design that offers ease of maintenance and accessibility for regular service checks to ensure long-term reliability.