The SP-I Slew Drive is a specific type of slewing drive that typically refers to a single-row four-point contact ball bearing slewing drive. This configuration is designed for precision, moderate to high load capacity, and compactness, making it suitable for a variety of applications where precise rotational movement and load support are required.

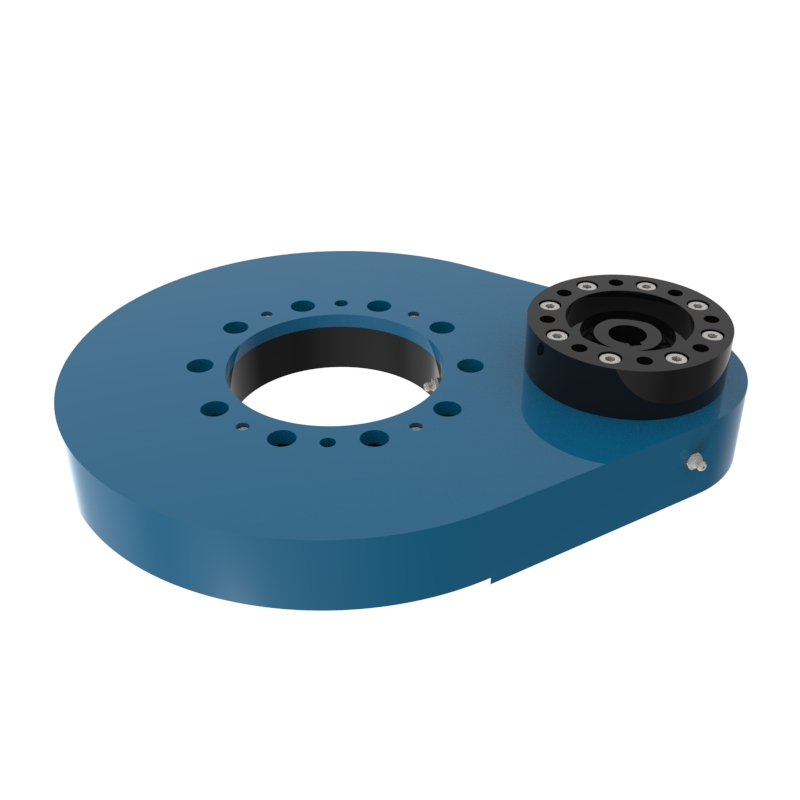

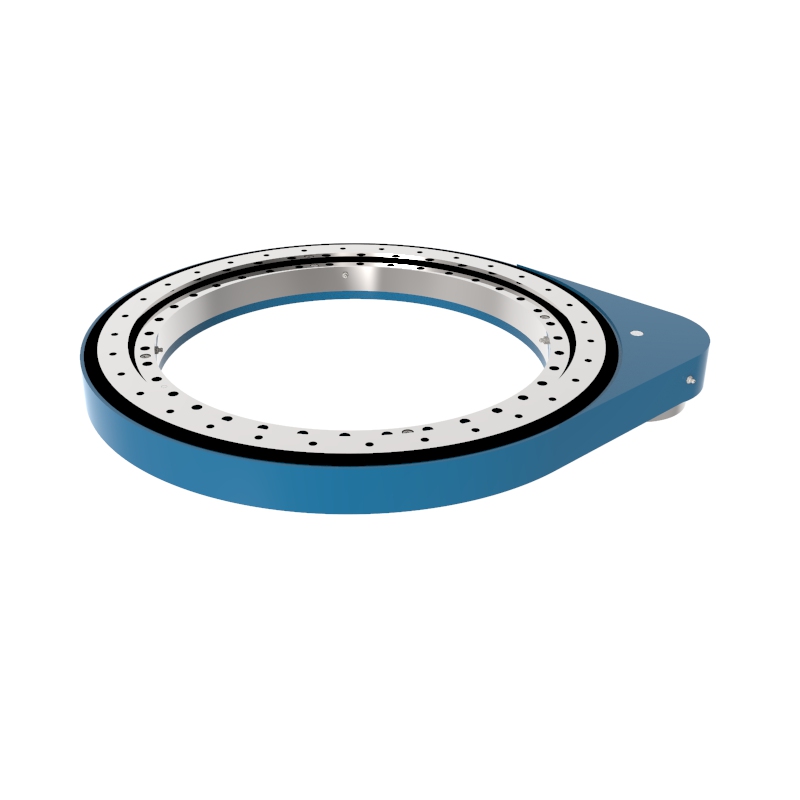

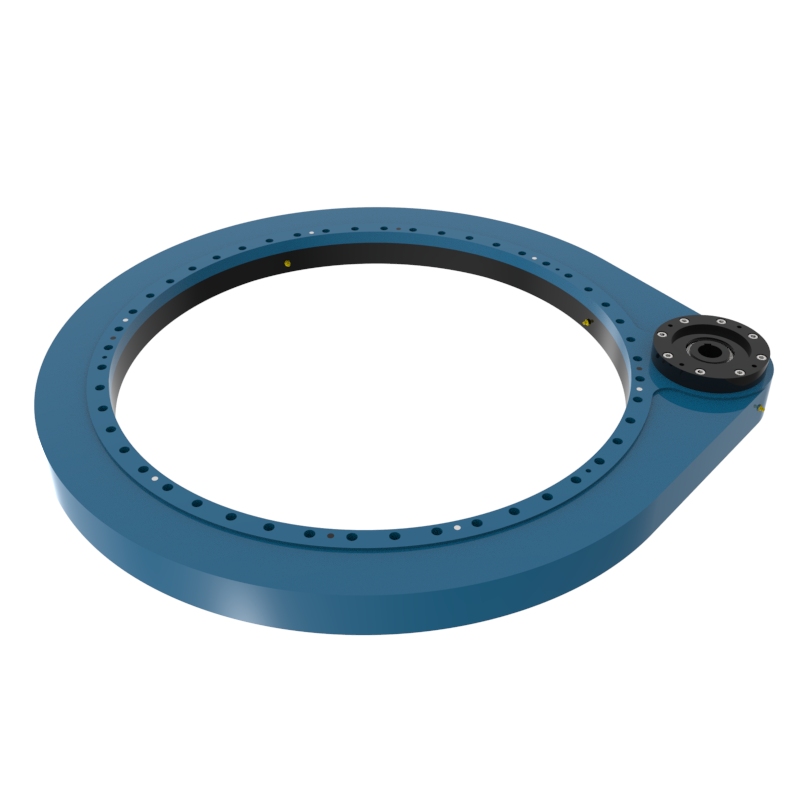

Lightweight Slewing Ring Gear Drive SP-I 0229

SP-I 0229 gear slewing drive is a highly efficient gear reduction transmission device, which is widely used in the automatic slewing of industrial machinery, especially in the occasions that require high precision and high speed.

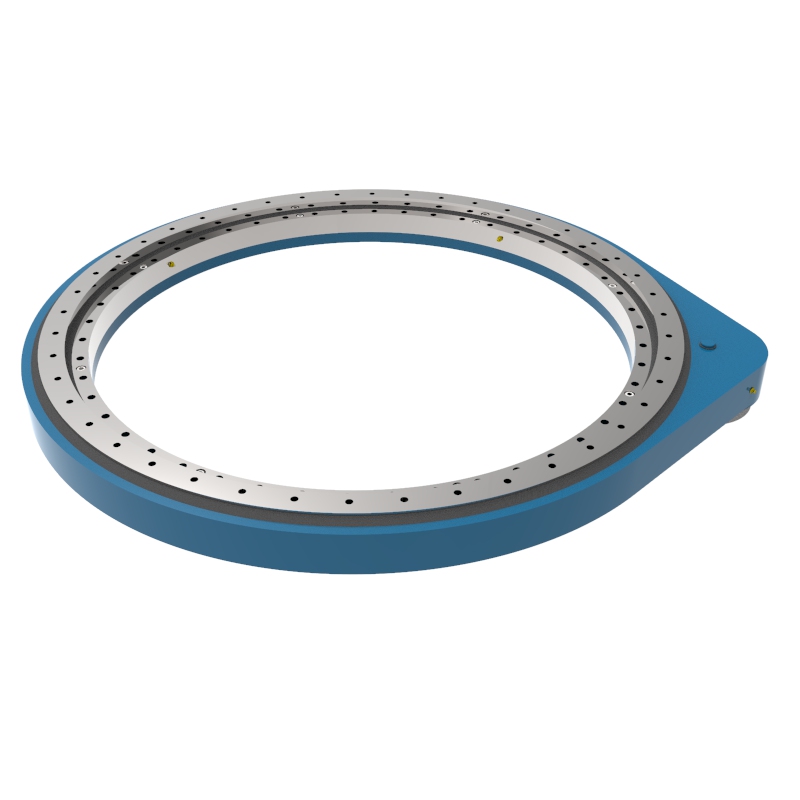

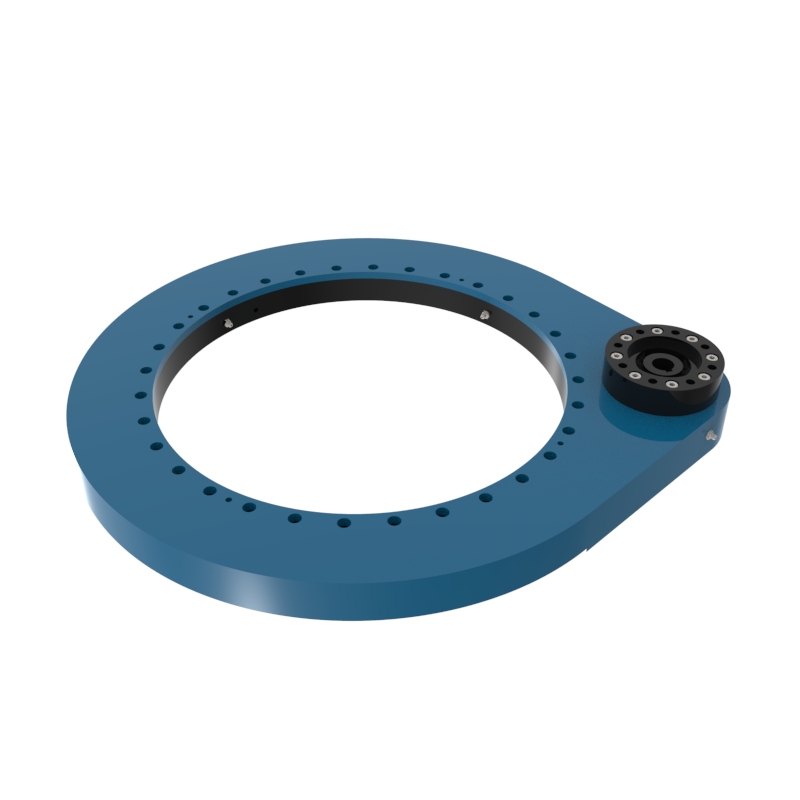

Read More Get A QuoteLightweight Slewing Ring Gear Drive SP-I 1091

The SP-I 1091 gear slewing drive is a highly efficient gear reduction transmission device, widely used in the automatic slewing of industrial machinery—particularly in applications requiring high precision, high torque, and reliable speed control.

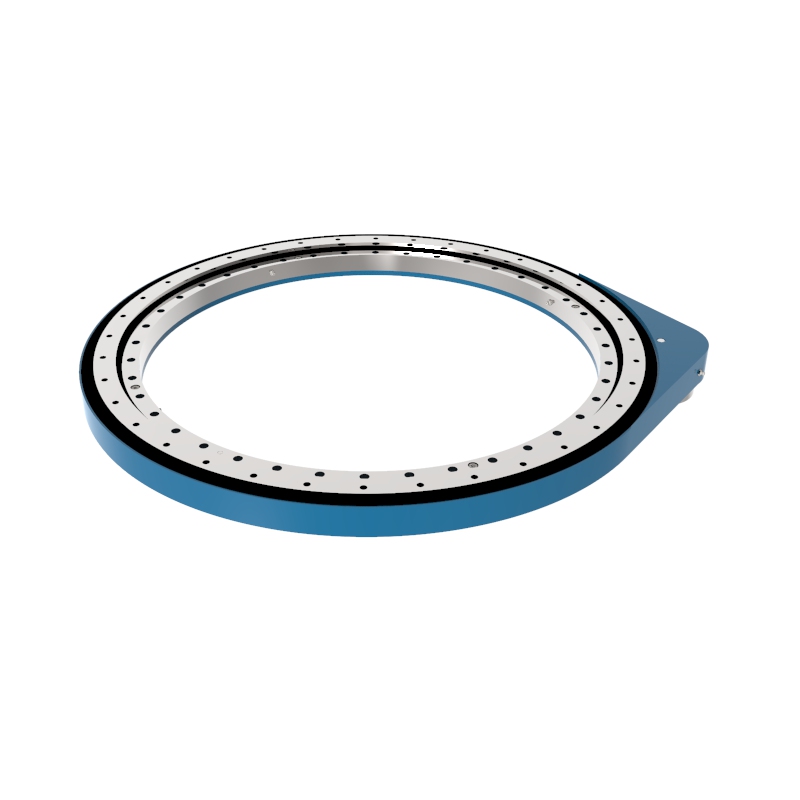

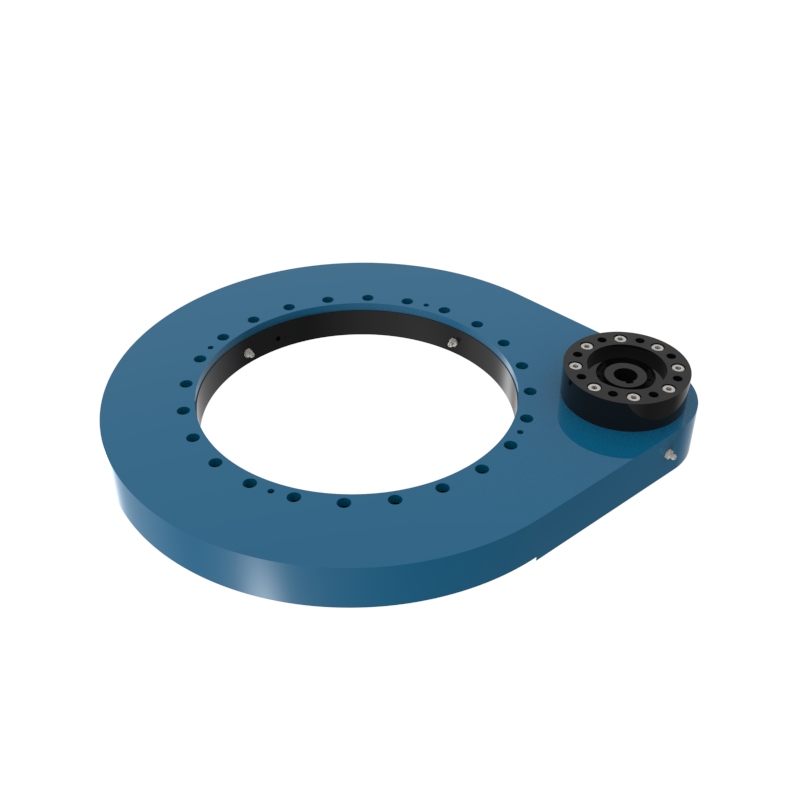

Read More Get A QuoteLightweight Slewing Ring Gear Drive SP-I 0841

The SP-I 0841 slewing drive is a robust and compact spur gear slewing solution, engineered for applications requiring precise, stable rotary motion under high load and speed conditions.

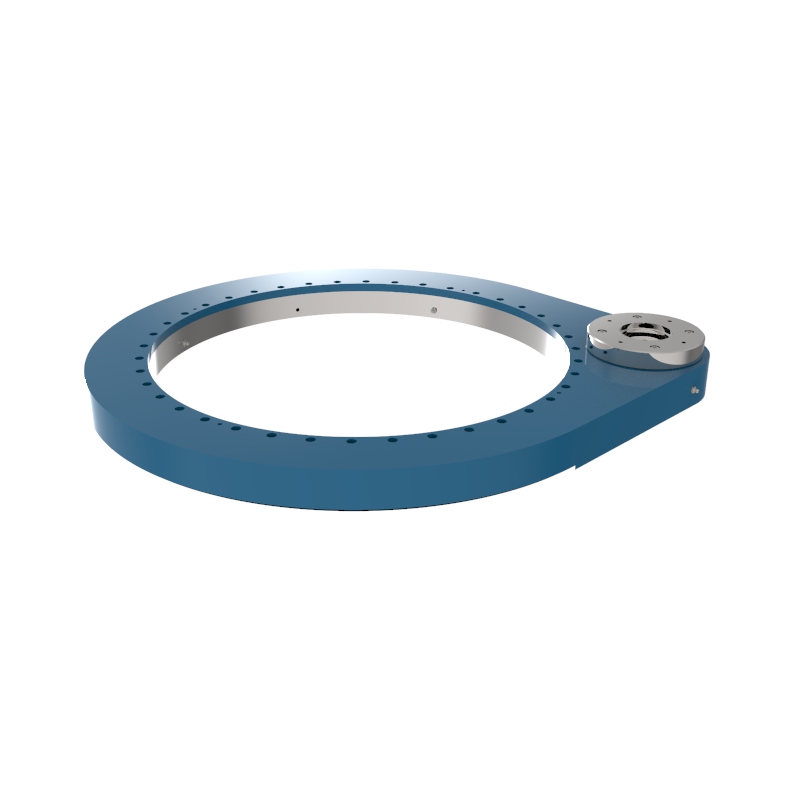

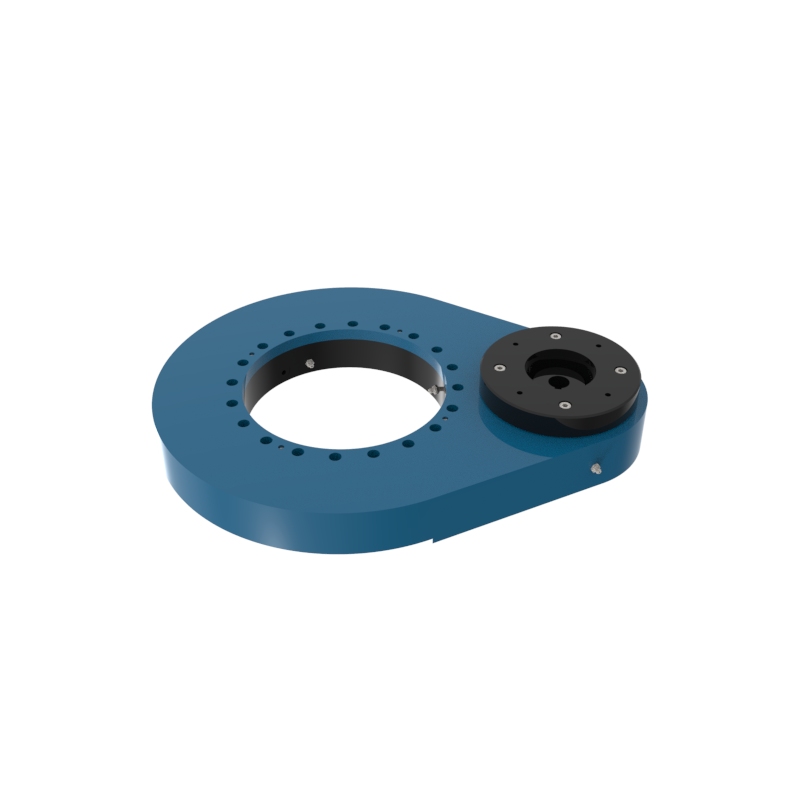

Read More Get A QuoteLightweight Slewing Ring Gear Drive SP-I 0741

SP-I 0741 gear slewing drive is a highly efficient gear reduction transmission device, which is widely used in the automatic slewing of industrial machinery, especially in the occasions that require high precision and high speed.

Read More Get A QuoteLightweight Slewing Ring Gear Drive SP-I 0641

SP-I 0641 is a compact and lightweight spur gear slewing drive engineered for high-precision rotary motion under dynamic and static load conditions.

Read More Get A QuoteLightweight Slewing Ring Gear Drive SP-I 0541

The SP-I 0541 is a lightweight external gear slewing drive designed for high-load, high-speed rotary applications. Featuring an integrated slewing bearing and a 10.4:1 gear reduction ratio, this model delivers reliable torque transmission and excellent structural rigidity.

Read More Get A QuoteLightweight Slewing Ring Gear Drive SP-I 0411

SP-I 0411 gear slewing drive is a highly efficient gear reduction transmission device, which is widely used in the automatic slewing of industrial machinery, especially in the occasions that require high precision and high speed.

Read More Get A QuoteLightweight Slewing Ring Gear Drive SP-I 0311

SP-I 0311 gear slewing drive is a highly efficient gear reduction transmission device, which is widely used in the automatic slewing of industrial machinery, especially in the occasions that require high precision and high speed.

Read More Get A QuoteLightweight Slewing Ring Gear Drive SP-I 0941

SP-I 0941 gear slewing drive is a highly efficient gear reduction transmission device, which is widely used in the automatic slewing of industrial machinery, especially in the occasions that require high precision and high speed.

Read More Get A Quote

Design of SP-I Slew Drive

Single-Row Four-Point Contact Ball Bearing: This type of bearing is characterized by a single row of balls that contact the raceway at four points. It can support axial, radial, and moment loads from any direction. The design allows for compactness and high rigidity.

Integrated Gear System: The SP-I slew drive typically incorporates an internal or external gearing system on the slewing ring, allowing for a gear reduction and torque multiplication. This gearing can be matched with various types of motors (electric, hydraulic, etc.).

Sealed Housing: To protect the internal components from environmental contaminants and to ensure durability and reliability, the SP-I slew drive is often enclosed in a sealed housing.

Features of SP-I Slew Drive

Compact Design: The integration of the slewing ring and drive components into a single unit offers a compact footprint, ideal for applications with limited space.

High Load Capacity: Despite its compact size, the four-point contact design allows it to handle significant loads in multiple directions.

Versatility: It can be adapted to various operating conditions and motor types, enhancing its application across different industries.

Precision: Offers precise control over rotational movement, making it suitable for applications requiring accurate positioning.

Ease of Installation: The unitized design simplifies the installation process, reducing assembly time and costs.

Typical Applications of SP-I Slew Drive

Solar Trackers: Used in solar photovoltaic and thermal applications to rotate panels towards the sun throughout the day, maximizing energy efficiency.

Satellite and Radar Dishes: Provides the necessary precision and reliability for positioning satellite dishes and radar systems.

Industrial Machinery: Applied in automation technology, assembly stations, and robotic arms where precise movement is critical.

Medical Equipment: Utilized in advanced medical imaging devices like CT scanners and MRI machines, where precise and smooth movement is essential.

Construction Equipment: Can be found in excavators, manlifts, and cranes where compact, high-load capacity rotation is needed.

Selection Considerations for SP-I Slew Drive

Load Requirements: Assess the maximum axial, radial, and moment loads to ensure the selected slew drive can handle the expected stresses.

Environmental Conditions: Consider factors like temperature extremes, presence of corrosive elements, and dust. Choose a slew drive with appropriate protective measures.

Motor Compatibility: Ensure that the slew drive is compatible with the intended motor type in terms of power, speed, and mounting.

Precision and Speed Requirements: Define the required precision and maximum speed to match the slew drive's capabilities with application needs.

Maintenance and Serviceability: Opt for a design that facilitates easy maintenance to minimize downtime and extend equipment life.