Excavator slewing bearings are pivotal components used in the construction and mining industries, enabling the excavator's upper structure (including the cabin, engine, and boom) to rotate smoothly and continuously relative to the undercarriage. These bearings must handle complex loads, including radial, axial, and moment loads, and withstand harsh operating conditions.

Excavator Travel Reduction Bearings

Excavator travel reducer bearings are also called side reducer bearings or tooth box bearings.

Read More Get A QuoteExcavator Slewing Bearing

The excavator slewing bearing is a force transmission element for the upper and lower bodies to make

Read More Get A QuoteFeatures of Excavator Slewing Bearings

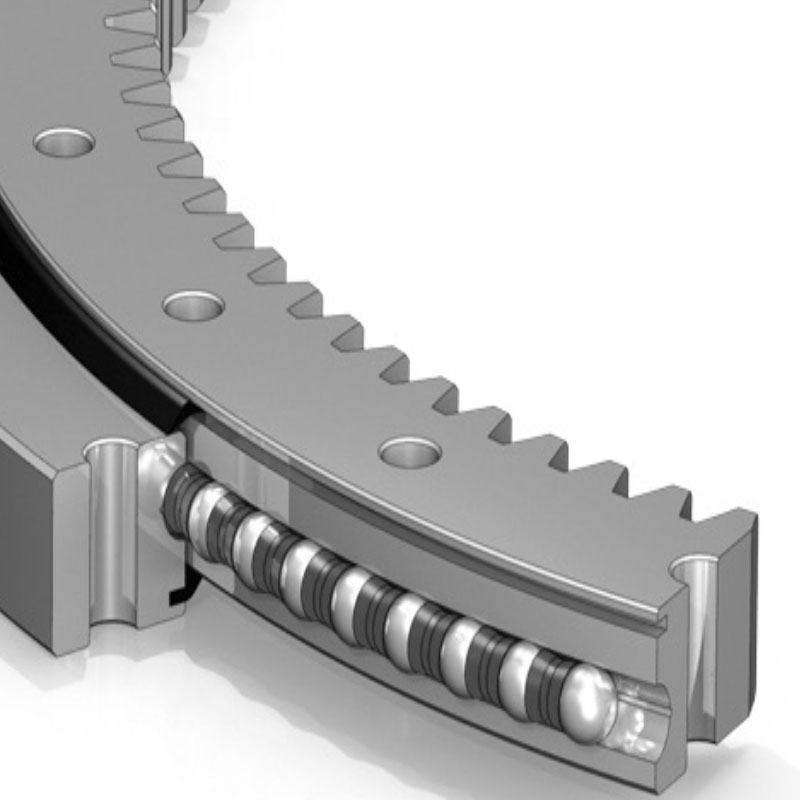

Robust Construction: Typically made from high-strength, hardened alloy steel, these bearings are designed to withstand the intense forces and wear associated with excavator operations.

Single or Double Row Configurations: Excavator slewing bearings can be designed with single or double row configurations depending on the size of the excavator and the load requirements. Double row bearings are often preferred for larger excavators due to their increased load capacity.

Gearing Options: These bearings generally come with internal or external gearing, allowing them to integrate seamlessly with the excavator’s drive system for rotation.

Sealing Systems: High-quality sealing is crucial for protecting the bearing from dirt, debris, and water, which are prevalent in excavation sites. Effective seals help maintain lubrication and prevent contamination, extending the bearing's service life.

Raceway and Rolling Element Design: The raceways are designed to provide optimal contact with the rolling elements (balls or rollers), ensuring even distribution of loads and reducing stress concentrations.

Advantages of Excavator Slewing Bearings

Durability: Engineered to endure tough conditions, including heavy loads, impacts, and environmental contaminants.

High Load Capacity: Capable of supporting the combination of radial, axial, and moment loads typically experienced during digging and lifting operations.

Integrated Gearing: The inclusion of gears within the bearing simplifies the mechanical design and enhances the overall efficiency of the excavator.

Compact and Efficient Design: Slewing bearings are designed to be compact yet robust, optimizing the use of space within the excavator’s structure.

Smooth Operation: Ensures the smooth and precise rotation of the excavator’s upper body, essential for efficient digging and material handling.

Common Applications of Slewing Bearings in Excavators

Upper Structure Rotation: The primary application of slewing bearings in excavators is to enable the rotation of the entire upper structure relative to the tracks, allowing the operator to maneuver the boom, arm, and bucket without needing to reposition the entire machine.

Boom and Arm Joints: In larger or more complex excavator models, additional slewing bearings might be used in the joints of the boom and arm to facilitate better articulation and movement.

How to select slewing bearing for Excavators?

Load Requirements: It is crucial to understand the specific load characteristics, including the maximum digging force and the weight of the materials being handled, to select the appropriate bearing.

Environmental Factors: The operating environment’s impact on material and seal selection must be considered, especially for excavators working in highly abrasive or corrosive environments.

Maintenance and Accessibility: Given the critical role and harsh operating conditions, ease of maintenance and accessibility for inspection and replacement are important factors.

Customization Needs: Excavators vary widely in size and function, necessitating customization of the slewing bearings in terms of size, load capacity, gearing, and sealing solutions.