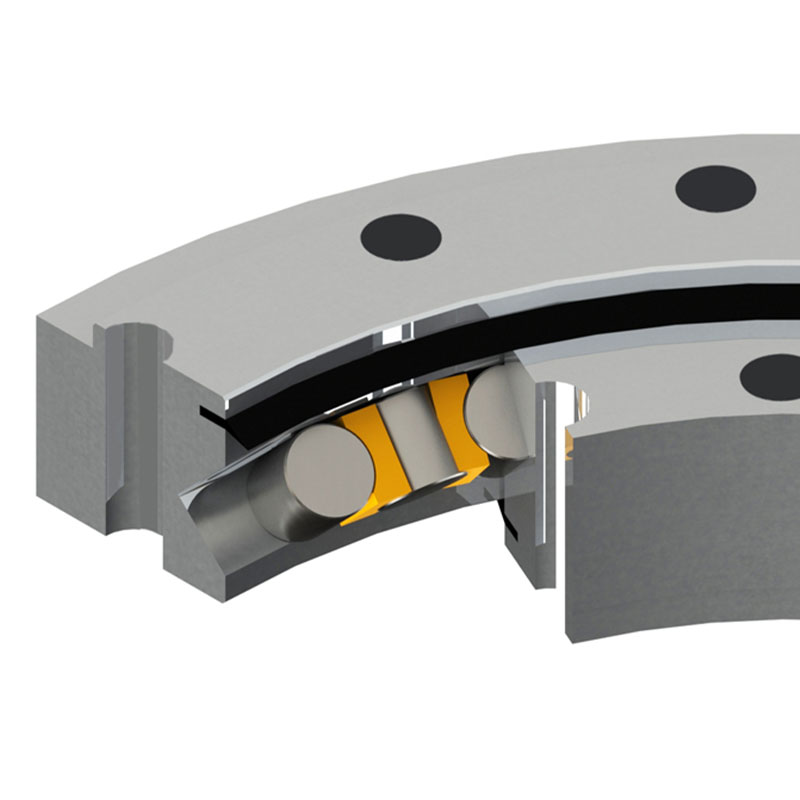

A Single Row Cross Roller Slewing Bearing is another type of slewing bearing, designed to handle loads from any direction with a high degree of stiffness and accuracy. Unlike the four point contact ball slewing bearing, which uses balls as rolling elements, the cross roller slewing bearing employs cylindrical rollers. These rollers are arranged in a single row and are alternately crossed at right angles to each other. This configuration allows for higher precision and greater load capacity, particularly in terms of axial and radial loads, as well as tipping moments.

Crossed Cylindrical Roller Slewing Bearing

The cross roller slewing bearing is mainly composed of an inner ring, an outer ring, rollers,

Read More Get A Quote

Design Features of Single Row Cross Roller Slewing Bearings

Roller Arrangement: The rollers are arranged in a cross pattern, which allows each roller to support a load from all directions. This design maximizes the bearing's ability to handle both radial and axial loads through a larger contact area.

Single Row of Rollers: Utilizing a single row helps to maintain a compact design while still providing high load capacity and stiffness.

Raceway Design: Typically, the raceways are designed to accommodate the crossed rollers, often with specialized surface treatments to enhance durability and load capacity.

Integral Gearing: Like other slewing bearings, these can also be equipped with internal or external gears, or no gears at all, depending on the application requirements.

Sealing System: Effective sealing systems are crucial to protect the bearing internals from debris and moisture, which can significantly extend the bearing's service life.

Advantages of Single Row Cross Roller Slewing Bearings

High Load Capacity: Excellent at handling combined loads (axial, radial, and moment loads) due to the line contact between rollers and raceways.

High Rotational Accuracy: The cross-roller design provides superior rotational precision, which is essential for applications requiring high precision.

Compact Design: Despite their high load capacity, these bearings are relatively compact and can save space in the application design.

Reduced Tilting: The arrangement of the rollers reduces the potential for tilting moments, which is crucial for applications involving high precision or heavy loads.

Stiffness: Offers greater rigidity compared to ball bearings, which can be beneficial in applications where minimal deformation is critical under load.

Common Applications

Robotic Arms and Manipulators: Used where precise movement and heavy load handling are required.

Medical Equipment: Employed in CT scanners and MRI machines for precise and stable movement.

Rotary Tables: Used in machine tools and manufacturing equipment where high precision and load capacity are necessary.

Satellite Antenna: Ideal for applications requiring precise positioning and stability.

Wind Turbines: Applied in pitch and yaw bearings to control the orientation of blades and nacelles.

How to select single row cross roller slew bearings?

Load Requirements: Detailed understanding of the axial, radial, and moment loads is essential for choosing the correct bearing size and specifications.

Precision Requirements: For applications requiring high precision, the bearing's rotational accuracy and stiffness must be considered.

Environmental Conditions: The choice of materials and seals should be influenced by the operating environment, including temperature ranges and potential exposure to corrosive elements.

Maintenance and Lifespan: Considerations for maintenance access and frequency, as well as expected service life, can influence the choice of bearing design and material.

Quality and Reliability: It is crucial to select high-quality bearings from reputable manufacturers to ensure reliability and operational efficiency.