The WE series slew drive represents a specialized configuration within the broader category of slewing drives, which are pivotal components in many modern mechanical systems requiring rotational motion control. These drives integrate gears, bearings, seals, and other structural elements to facilitate controlled, precise rotational movement under various load conditions. The WE series, in particular, is designed to offer robust performance in both industrial and commercial applications, characterized by its distinctive design and functionality.

Worm Gear Drive WE7

The Worm Gear Drive WE7 is an integrated drive component that efficiently handles axial, radial, and moment loads, featuring a self-locking mechanism for enhanced safety.

Read More Get A QuoteWorm Gear Drive WE9

The Worm Gear Drive WE9 is an integrated drive component featuring a worm shaft and worm wheel that provides high torque and self-locking capabilities in a compact design. Its key features include high efficiency, superior sealing with an IP65 rating, and

Read More Get A QuoteWorm Gear Drive WE12

The Worm Gear Drive WE12 is an integrated drive component featuring a worm shaft and worm wheel that provides high torque and self-locking capabilities in a compact design.

Read More Get A QuoteWorm Gear Drive WE14

Worm Gear Drive WE14 is an advanced integrated drive unit designed for high-torque, low-speed applications, featuring a self-locking mechanism for enhanced safety and reliability.

Read More Get A QuoteWorm Gear Drive WE17

Worm Gear Drive WE17 is a sophisticated drive component designed for various industrial applications. Comprising a sturdy base, a precisely engineered worm shaft, and a corresponding worm wheel, the WE17 is built to operate effectively in closed protectiv

Read More Get A QuoteWorm Gear Drive WE19

Worm Gear Drive WE19 is an integrated drive component designed to handle axial loads, radial forces, and overturning moments, featuring a self-locking mechanism and high efficiency for various industrial applications.

Read More Get A QuoteWorm Gear Drive WE25

The Worm Gear Drive WE25 is a high-precision, dustproof, and waterproof rotary drive system designed for heavy-duty applications like marine cranes and lifting equipment, offering impressive output torque, self-locking safety features, and versatility for various industrial uses.

Read More Get A QuoteWorm Gear Drive WE21

The Worm Gear Drive WE21 is an advanced, integrated rotary drive system designed for a wide range of industrial applications. Composed of key components such as a base, worm shaft, and worm wheel, the WE21 is engineered to operate efficiently within a sealed environment. This drive system can handle axial loads, radial forces, and overturning moments simultaneously, while its self-locking mechanism ensures secure operation even when power is lost. This makes the WE21 particularly suitable for ap

Read More Get A Quote

What is a WE Slew Drive?

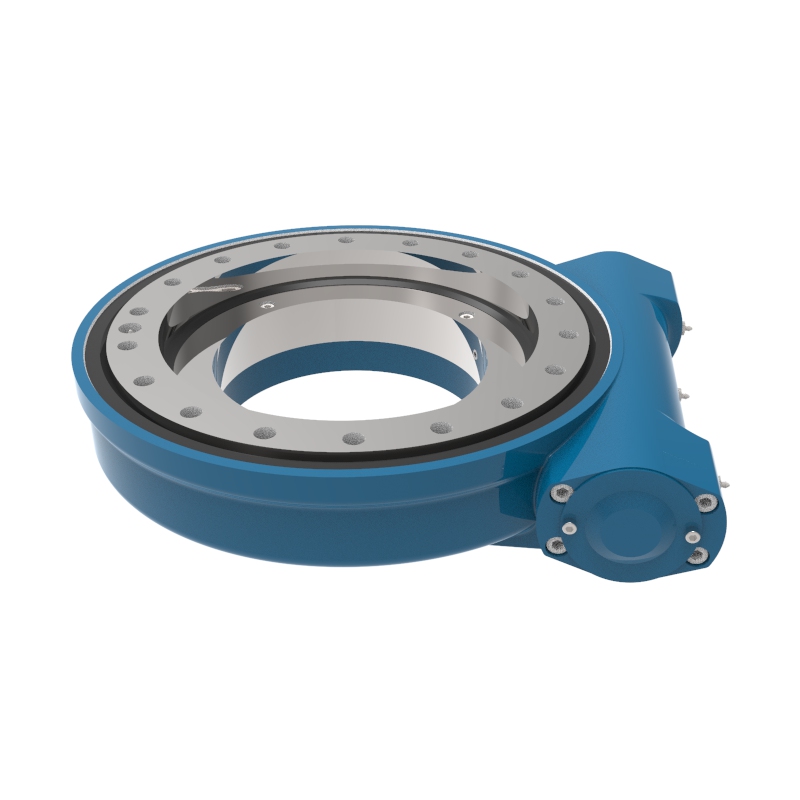

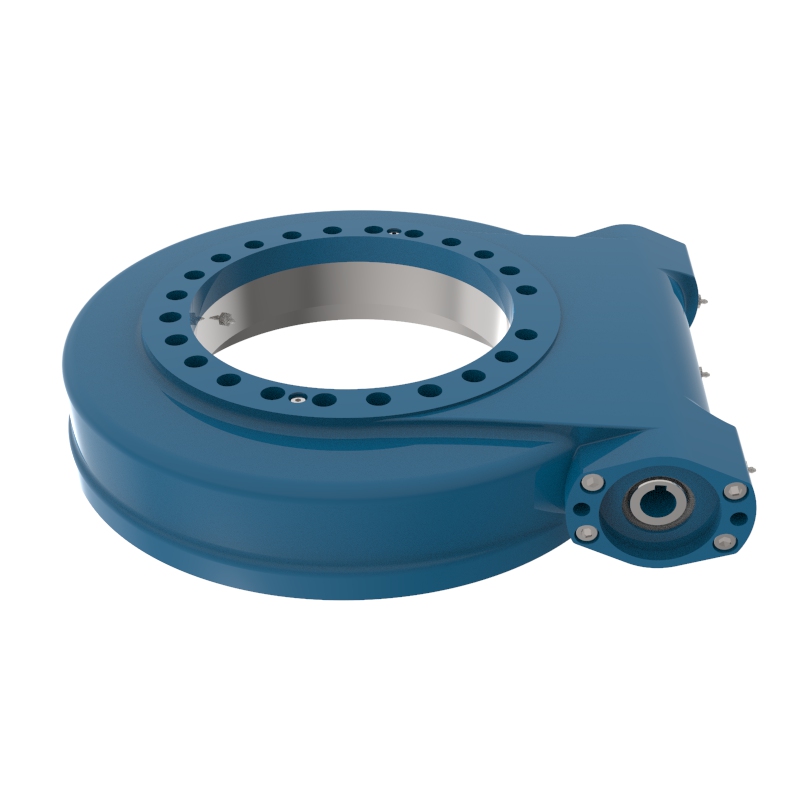

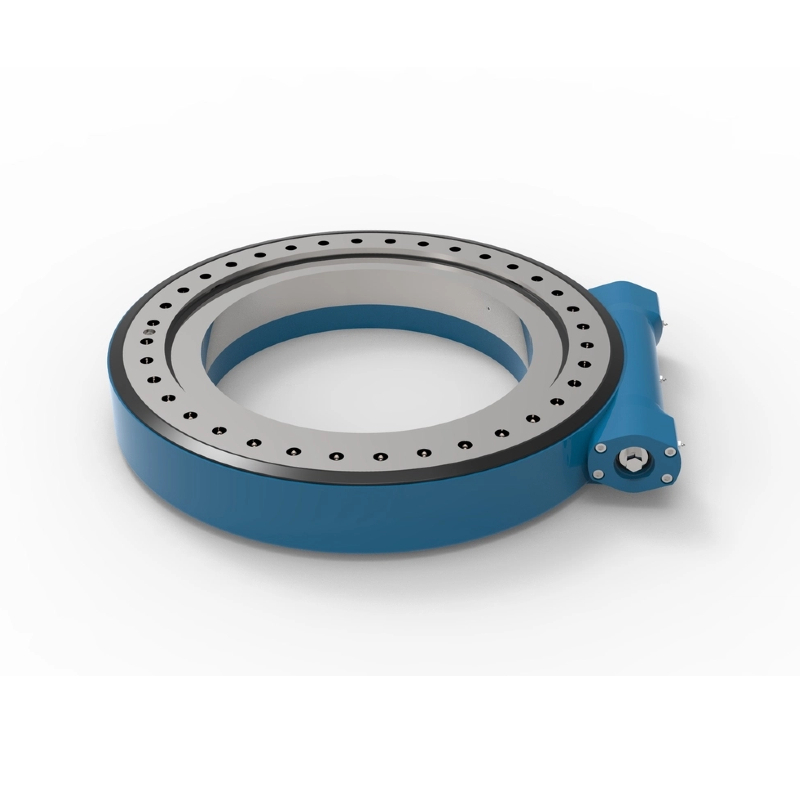

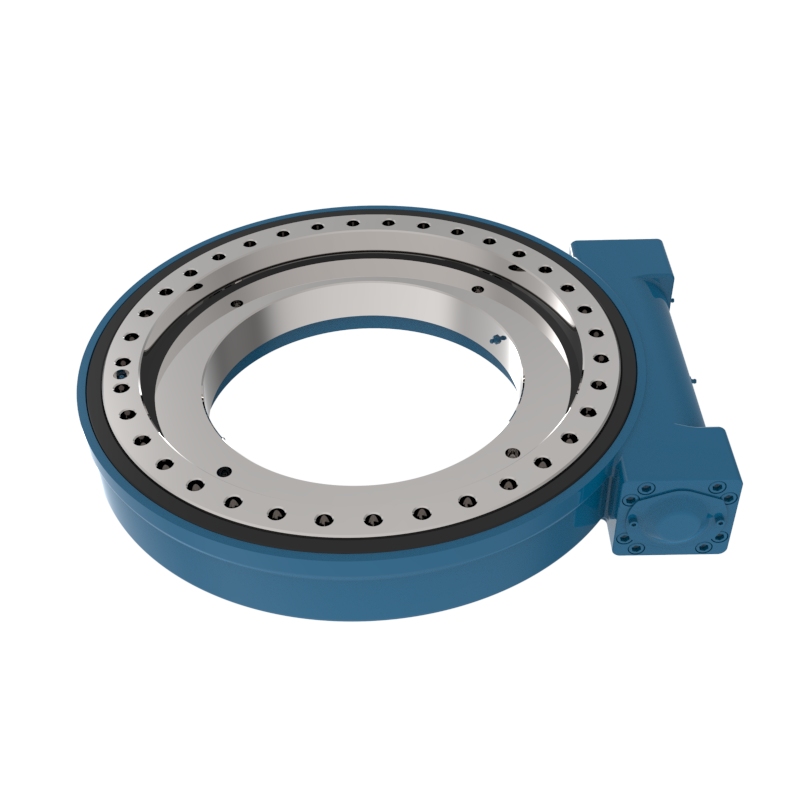

The WE slew drive is a type of enclosed gear drive mechanism that is typically used for applications requiring both high torque and precise rotational motion. The "WE" designation generally stands for "worm gear enclosed," which highlights its main operational mechanism and design feature: an enclosed worm gear that interacts with a slew ring to facilitate rotation. This design ensures protection against environmental elements, making it suitable for outdoor use.

Key Features of WE Slew Drives

Enclosed Housing: The WE slew drive's housing fully encloses the gears and bearings, protecting them from dust, dirt, and moisture. This feature extends the lifespan of the drive and reduces maintenance needs, particularly in harsh environments.

High Torque Capacity: Thanks to its worm gear design, the WE slew drive can handle significantly higher torque loads compared to other types of drives like spur gears, making it ideal for applications involving heavy loads.

Self-locking Mechanism: One of the notable advantages of the worm gear setup in WE slew drives is its inherent self-locking capability, which can prevent back-driving in case of power loss. This is essential for safety in many applications.

Versatility in Applications: These drives can be customized with different motors (electric, hydraulic, etc.) and can include options for different sensors and controls, making them adaptable to a wide range of operational requirements.

Precision Control: The gear ratio in the worm gear setup allows for precise movement control, which is crucial in applications where fine positioning is necessary.

Applications of WE Slew Drives

The robustness and versatility of the WE slew drive make it suitable for numerous applications across various industries:

Solar Trackers: In solar photovoltaic systems, WE slew drives are used to rotate solar panels following the sun’s path to maximize energy absorption throughout the day.

Wind Turbines: These drives can adjust the yaw and pitch of wind turbine blades to optimize the capture of wind energy, enhancing efficiency and power output.

Satellite and Radar Dishes: Precise positioning is critical for satellite and radar communication systems. WE slew drives provide the necessary accuracy and reliability for these applications.

Mobile Equipment: Various types of mobile cranes, aerial lifts, and other construction machinery utilize WE slew drives for movement and load handling.

Industrial Turntables and Positioners: Manufacturing and assembly processes often require the rotation of heavy loads or precise positioning of components, tasks well-suited to the capabilities of WE slew drives.

Selecting a WE Slew Drive

When choosing a WE slew drive for a specific application, several factors should be considered:

Load Specifications: Understanding the dynamic and static load requirements is crucial to select a drive that can handle the expected stresses without failure.

Environmental Conditions: The drive should be capable of operating effectively under the environmental conditions of the application site, including temperature extremes and potential contaminant exposure.

Required Precision: Depending on the application, the precision and repeatability of the drive's movement might be critical factors.

Integration Needs: The slew drive should be compatible with existing systems, both mechanically and electrically, to ensure smooth integration and operation.

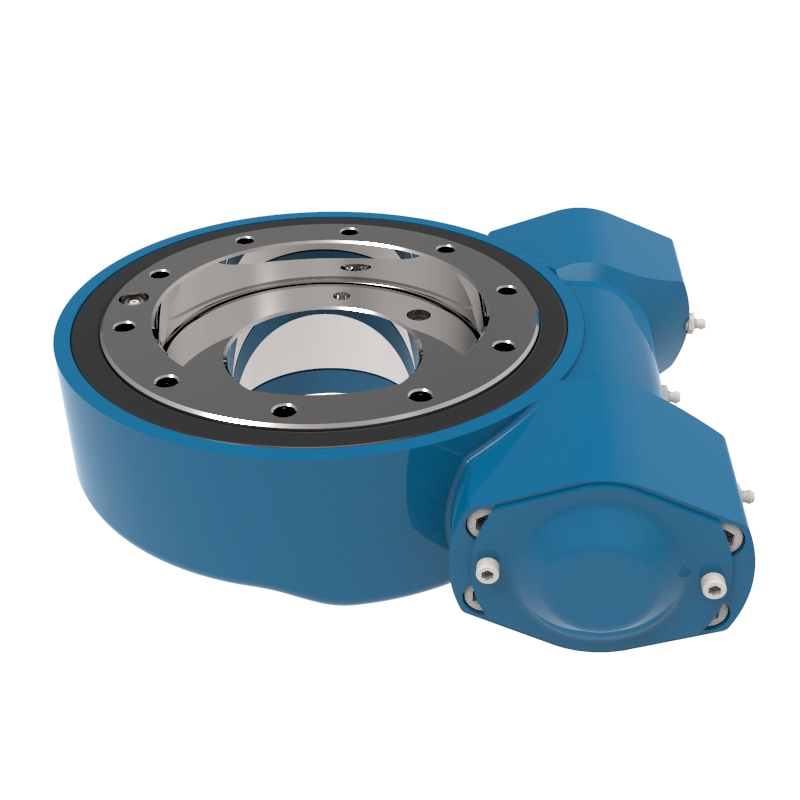

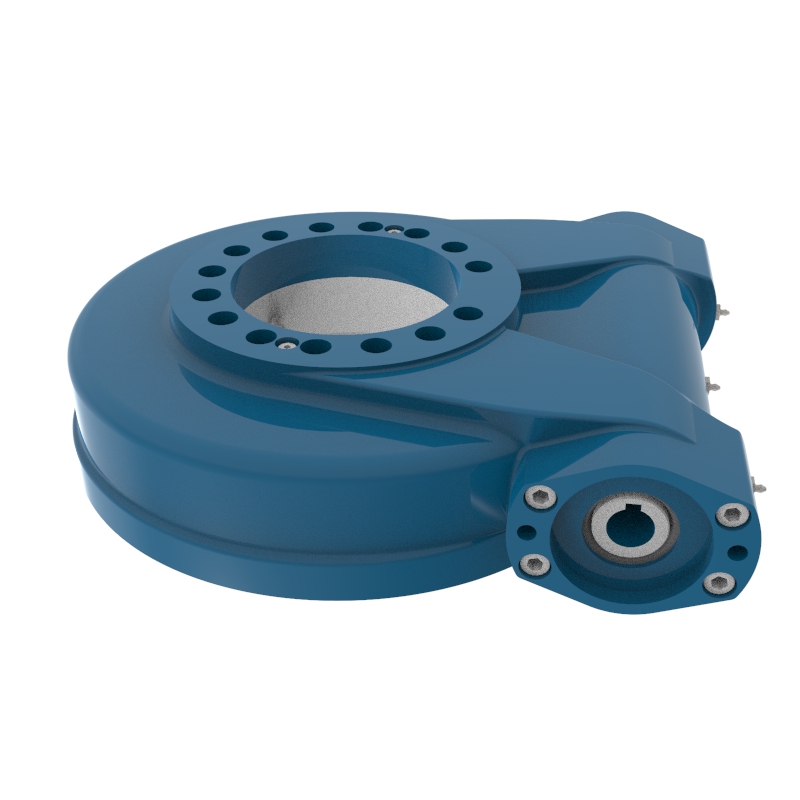

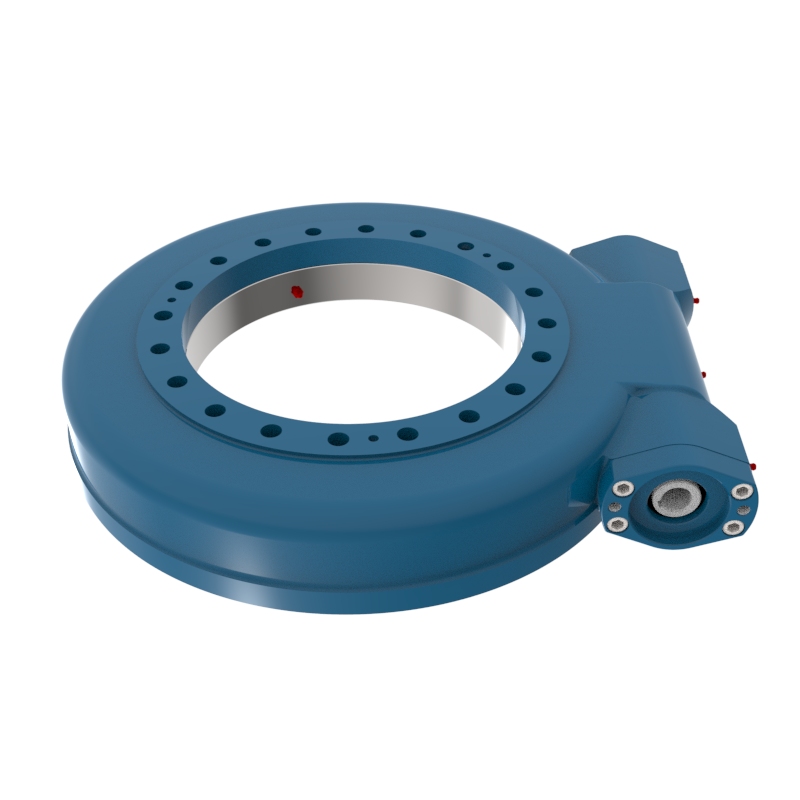

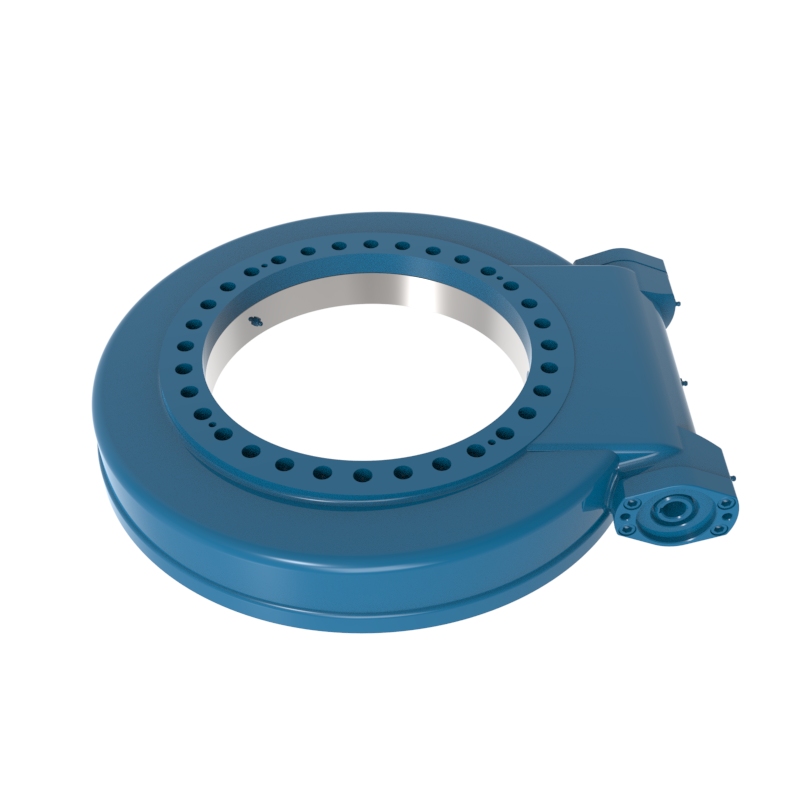

Lyradrive WE Series Heavy-Duty Fence-Type Slewing Drive

The Lyradrive WE Series Heavy-Duty Fence-Type Slewing Drive is engineered for demanding engineering and industrial applications where powerful rotational motion, stability, and precision are essential. Built with advanced structural design and premium materials, the WE Series delivers superior performance in heavy-load environments.

Key Advantages

1. Robust Fence-Type Design

The innovative fence-type structure enhances stability and ensures exceptional load-bearing capacity. The circular fence design provides reliable support for heavy-duty operations, even under extreme conditions.

2. Premium High-Strength Materials

Manufactured with high-grade materials such as 50Mn and 42CrMo, the WE Series offers outstanding durability, wear resistance, and long service life in tough working environments.

3. Exceptional Heavy-Load Capacity

Compared to standard slewing drives, the WE Series is purpose-built for significantly higher load capacities. This makes it ideal for applications involving large-scale equipment handling, heavy cargo lifting, and other high-load operations.

4. Precision Positioning Performance

Designed with high-precision positioning technology, the WE Series ensures accurate alignment and reliable placement of equipment or materials—an essential advantage for industries where precision and safety are critical.

The Lyradrive WE Series Heavy-Duty Fence-Type Slewing Drive combines strength, precision, and reliability, making it the perfect choice for modern engineering and industrial heavy-duty applications.