A WED slew drive is a type of slewing drive, which is a gearbox that can handle radial and axial loads while transmitting torque for rotation. The slewing ring bearing at the center of the drive allows it to withstand high moment loads.

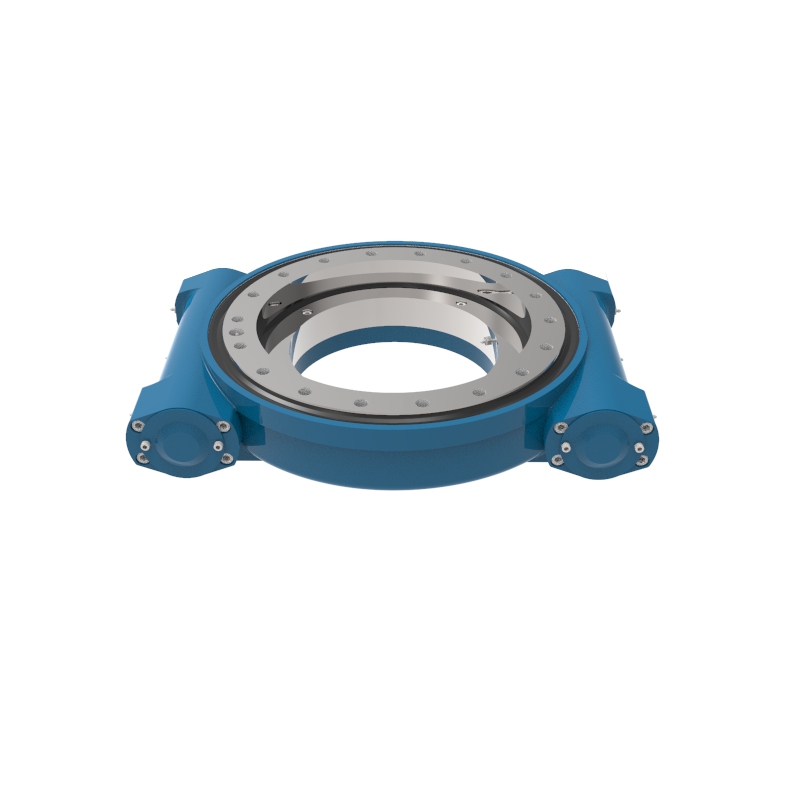

Double Worm Slewing Drive WED14

The Double Worm Slewing Drive WED14 is a high-performance, self-locking transmission unit that enhances torque, load capacity, and safety for heavy-duty applications, with customization options available to suit specific industry needs.

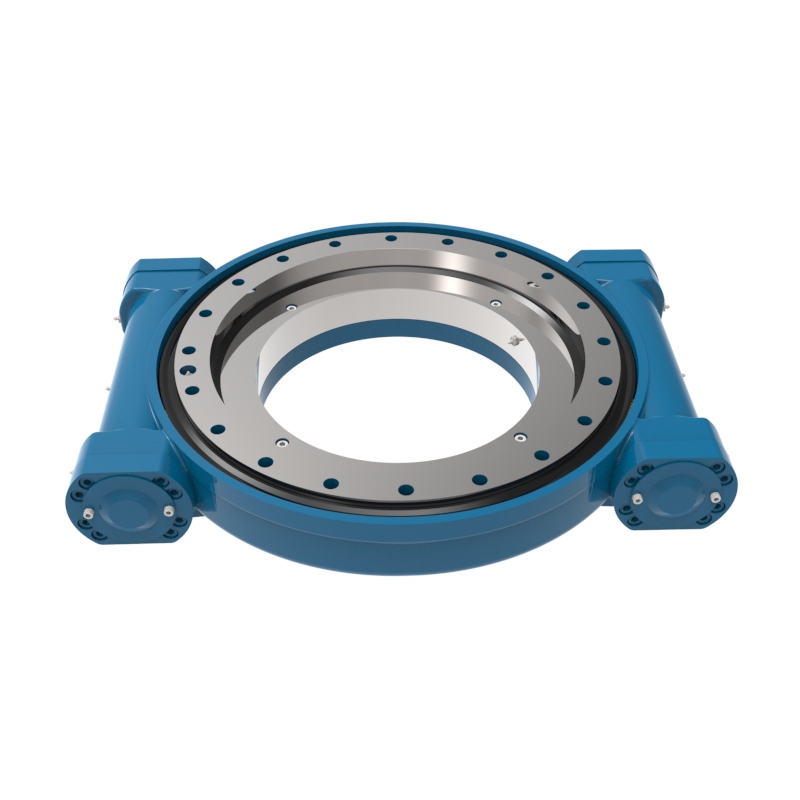

Read More Get A QuoteDouble Worm Slewing Drive WED17

The Double Worm Slewing Drive WED17 is a high-performance, compact rotational drive system designed for heavy-duty applications, offering high torque, self-locking functionality, and excellent durability in harsh environments, with customizable options to meet specific operational needs.

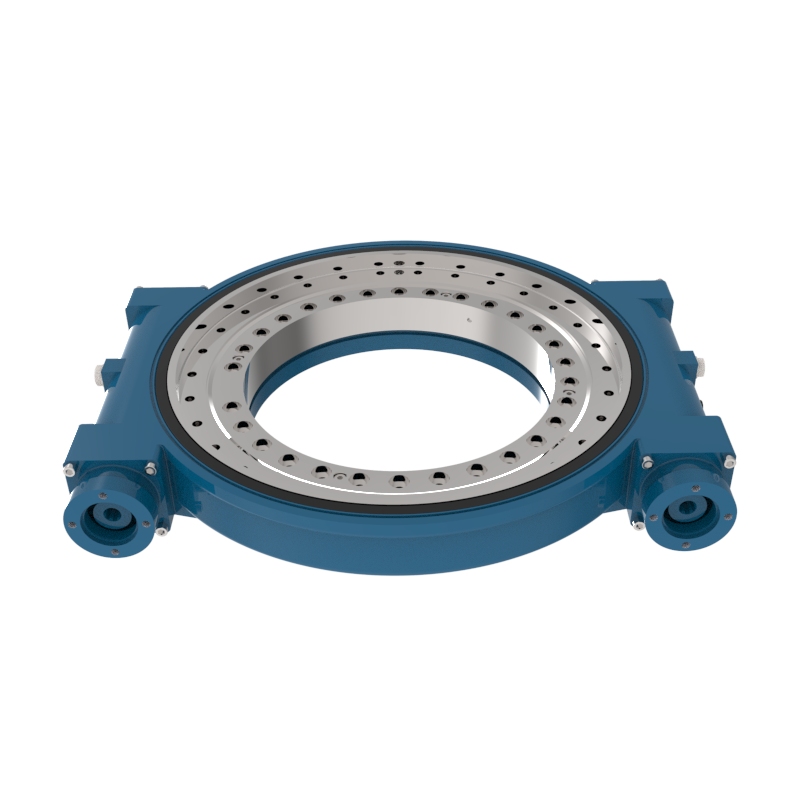

Read More Get A QuoteDouble Worm Slewing Drive WED21

Output Torque:48kN.mTilting Moment Torque:203kN.mHolding Torque:179.8kN.mGear Ratio:90:1Tracking Precision:≤0.13°

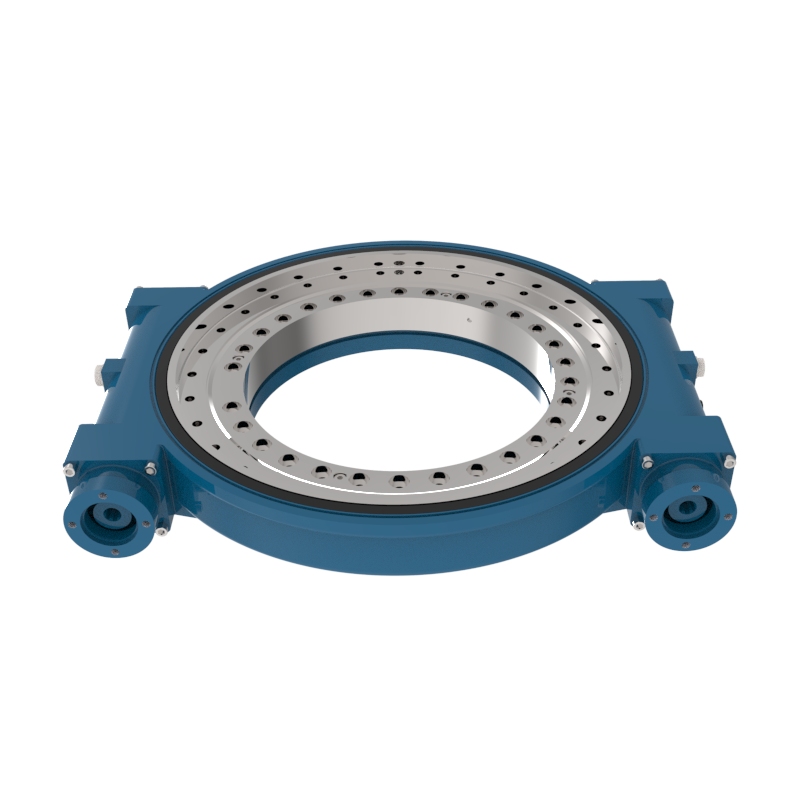

Read More Get A QuoteDouble Worm Slewing Drive WED 25

The Double Worm Slewing Drive WED25 is a high-performance, heavy-duty mechanical component designed to deliver superior rotational motion for large-scale industrial machinery. It is an advanced slewing drive that incorporates two worms driving a single worm wheel, providing higher output and holding torque than traditional slewing drives. The WED25 is specifically engineered to handle heavy loads and extreme operational environments, offering enhanced precision, reliability, and safety in a comp

Read More Get A Quote

What is WED slew drive?

A WED slew drive is a type of slewing drive, which is a gearbox that can handle radial and axial loads while transmitting torque for rotation. The slewing ring bearing at the center of the drive allows it to withstand high moment loads.

Features of WED Slew Drive

High Load Capacity: The WED slew drive is designed to handle both radial and axial loads effectively, making it suitable for heavy-duty applications.

Integrated Slewing Ring Bearing: The center of the drive features a slewing ring bearing that can withstand high moment loads, which is crucial for applications involving significant tilting forces.

Compact Design: Combining the bearing and drive mechanism into a single unit not only saves space but also simplifies the design and installation process.

Versatility: These drives can be adapted to various operating conditions and can be equipped with different motor types (electric, hydraulic, etc.) based on application needs.

Precision Control: Provides accurate control of rotational movement, which is essential for applications requiring precise positioning.

Durability: Built to withstand harsh environments and maintain performance over long operational periods.

Applications of WED Slew Drive

Renewable Energy: Particularly in solar trackers where precise positioning is crucial to follow the sun’s path and maximize energy capture.

Construction Equipment: Used in cranes, excavators, and aerial lift platforms where controlled rotational movement is necessary.

Industrial Machinery: Applied in turntables, assembly platforms, and other machinery requiring rotation.

Mobile Applications: Such as in the rotation mechanisms of mobile cranes and forest machinery.

Marine and Offshore Technology: For positioning devices and operational platforms in marine environments.

How to Select a WED Slew Drive?

Determine Load Requirements: Assess the maximum radial, axial, and moment loads the slew drive will need to support. This will guide the size and type of slew drive required.

Evaluate Environmental Conditions: Consider the operating environment (temperature, exposure to corrosive elements, dust, etc.) to select a slew drive with appropriate protection and materials.

Motor Compatibility: Decide on the type of motor based on availability, power source, and integration capabilities. Check if the slew drive is compatible with your preferred type of motor.

Precision and Speed Needs: Identify the necessary precision and maximum speed requirements for the application to ensure the slew drive meets these specifications.

Installation Space: Measure the available space to ensure the slew drive will fit without requiring modifications to existing structures.

Maintenance and Serviceability: Consider ease of maintenance and access to spare parts. A slew drive that is easy to service will minimize downtime and operational costs.