Light load slewing bearings are a specific type of bearing designed to accommodate rotations with relatively low axial, radial, and moment loads. These bearings are essential in applications where the primary requirements are rotational movement and positioning rather than the handling of heavy loads. Light load slewing bearings are used in various industries, including automation, light machinery, and small-scale applications.

Flanged Four Contact Ball Slewing Bearing

Flange type slewing bearing also belongs to four-point contact ball slewing bearing.

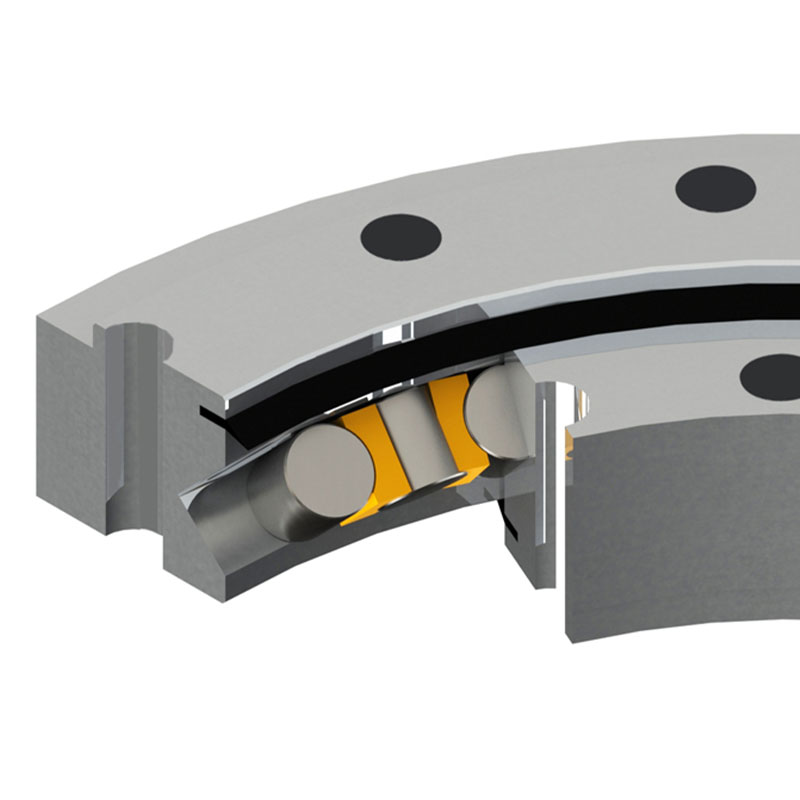

Read More Get A QuoteCrossed Cylindrical Roller Slewing Bearing

The cross roller slewing bearing is mainly composed of an inner ring, an outer ring, rollers,

Read More Get A Quote

Design of Light Load Slewing Bearings

Ring Configuration: Typically, light load slewing bearings consist of one or two rings with an integral gear system. The gears can be internal, external, or without gears, depending on the application requirements.

Rolling Elements: These bearings usually incorporate ball bearings rather than roller bearings, as ball bearings are sufficient to handle lighter loads and provide smooth rotational movement.

Material: The materials used are often standard steel or lightweight alloys, which provide enough strength for light loads while keeping the overall weight of the bearing low.

Sealing System: Like other slewing bearings, light load versions also include seals to protect the internal rolling elements from dust, debris, and moisture, ensuring reliable operation and longevity.

Features of Light Load Slewing Bearings

Low Weight: Designed to be lightweight, these bearings are easier to handle and reduce the overall weight of the machinery.

Compact Design: They are typically more compact, making them ideal for applications with limited space.

Ease of Movement: The use of ball bearings and light materials allows for smooth and easy rotational movements.

Cost-Effective: Generally less expensive than heavy-duty slewing bearings due to the simpler design and lower material costs.

Versatility: Can be customized with different gear configurations and sizes to fit a wide range of applications.

Typical Applications of Light Load Slewing Bearings

Solar Trackers: Used in solar photovoltaic and thermal applications to rotate solar panels following the sun’s path, optimizing energy capture.

Packaging Machinery: Integral in various stages of packaging for rotation and precise positioning of goods.

Medical Equipment: Employed in devices like medical chairs and tables, where smooth and controlled movement is critical.

Light Cranes and Manipulators: Used in light-duty cranes and robotic arms for handling and assembling small components.

Revolving Stages and Displays: Common in entertainment and exhibition sectors for rotating stages and display platforms.

Selection Considerations for Light Load Slewing Bearings

Load Assessment: It is crucial to accurately evaluate the maximum expected loads (axial, radial, and moment) to select a bearing that can perform reliably without being oversized.

Environmental Factors: Consider the operating environment, including potential exposure to corrosive elements, temperature extremes, and contamination, to choose the appropriate sealing and material options.

Space and Integration: Ensure the selected bearing fits within the available space and can be integrated seamlessly with other system components.

Maintenance and Lifespan: Consider the expected operational lifespan and maintenance requirements, opting for designs that offer ease of maintenance and long service life.

Supplier Reputation: Choose bearings from reputable manufacturers to ensure quality and reliability, as well as support for customization and technical assistance.