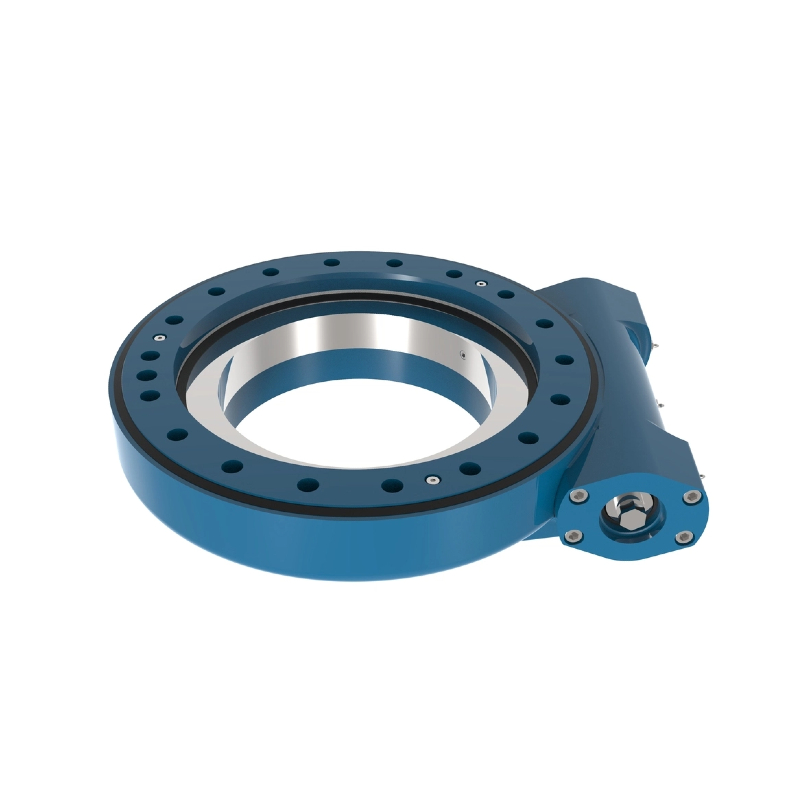

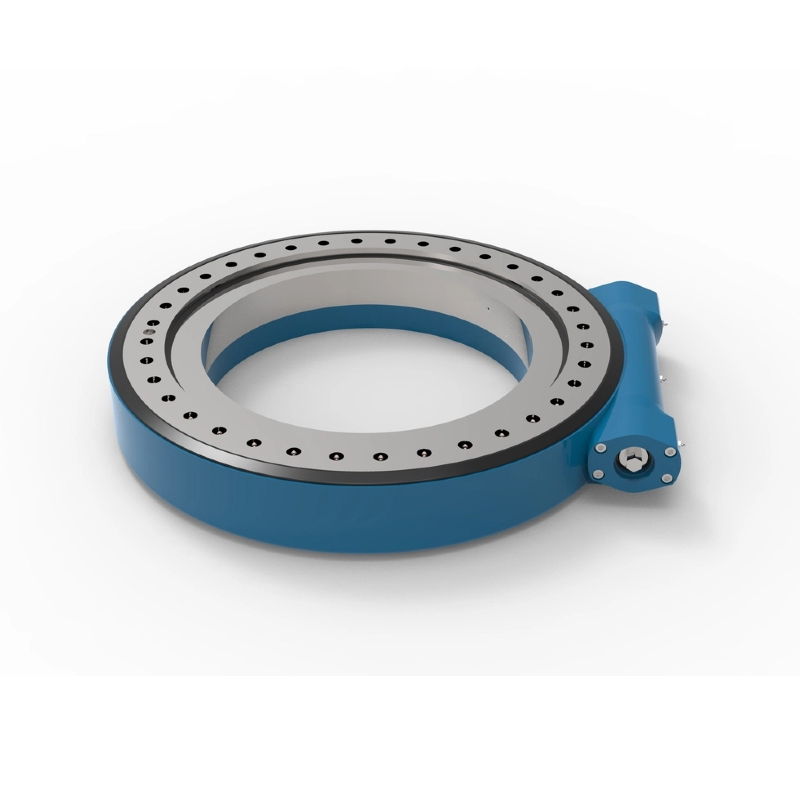

The SE series slew drive is another popular type of slewing drive, widely used in various mechanical and engineering applications where precise rotational movement and load-bearing capabilities are required. The "SE" typically stands for "slew drive enclosed," emphasizing the enclosed nature of the gearbox which protects its internal components from environmental factors. This series is particularly known for its robustness and versatility in handling complex loading conditions.

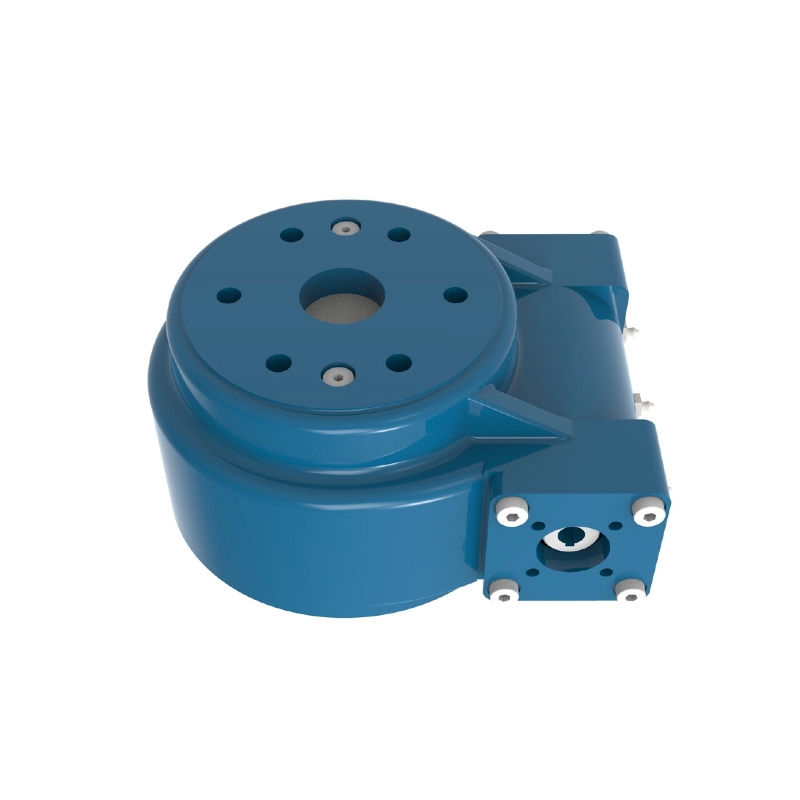

Enveloping Slewing Drive SE5

The Enveloping Slewing Drive SE5 series is an advanced integrated transmission component designed to offer robust and reliable performance. It is composed of key parts, including a base, worm, and worm gear.

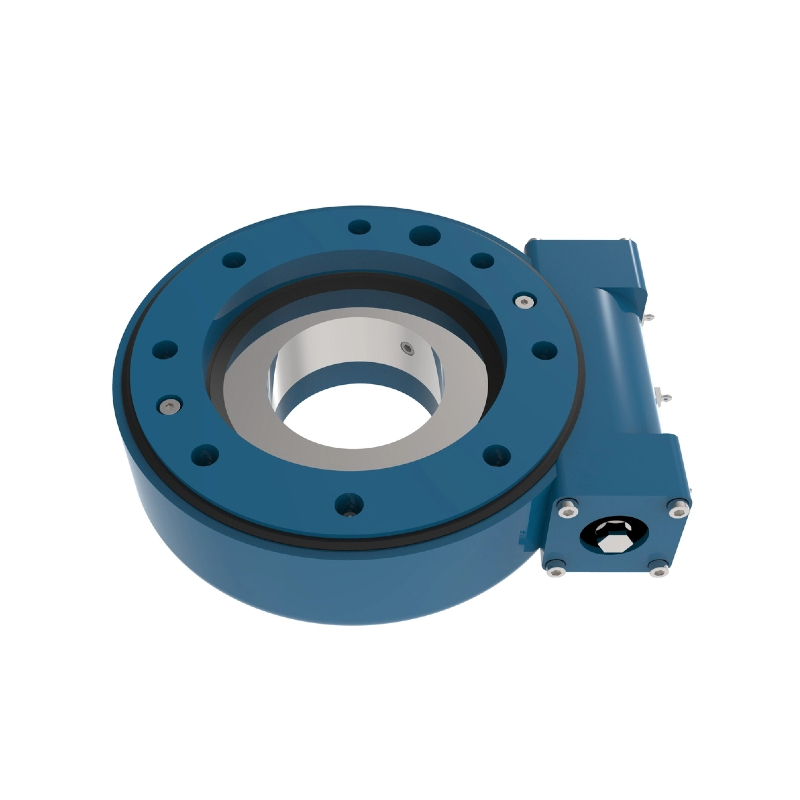

Read More Get A QuoteEnveloping Slewing Drive SE7

The Enveloping Slewing Drive SE7 is an integrated, high-performance transmission unit designed to provide efficient rotational motion under heavy loads. It consists of a base, worm gear, and worm wheel, all housed in a sealed protective casing. This advanced slewing drive system can simultaneously bear axial, radial, and tilting moment loads while offering a self-locking feature. The unique design of the enveloping worm allows for a high number of teeth engagement—typically 4 to 5 teeth—between

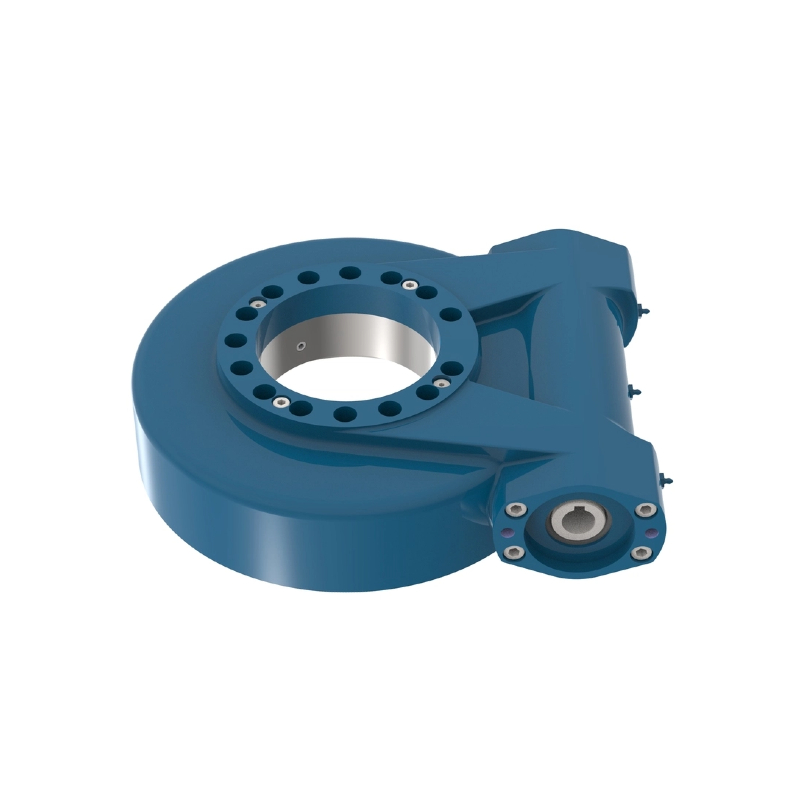

Read More Get A QuoteEnveloping Slewing Drive SE9

The Enveloping Slewing Drive SE9 offers reliable, high-torque performance with excellent sealing and self-locking features, making it ideal for demanding applications in harsh environments, and is customizable to meet specific operational needs.

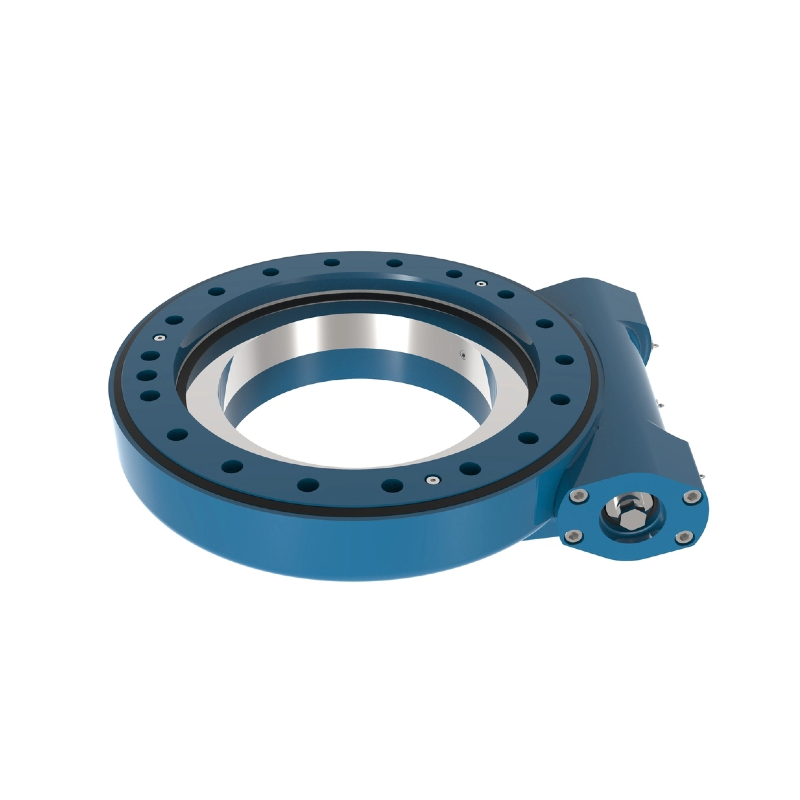

Read More Get A QuoteEnveloping Slewing Drive SE12

The Enveloping Slewing Drive SE12 series is an advanced integrated transmission component designed to offer robust and reliable performance. It is composed of key parts, including a base, worm, and worm gear.

Read More Get A QuoteEnveloping Slewing Drive SE14

The Enveloping Slewing Drive SE12 series is an advanced integrated transmission component designed to offer robust and reliable performance. It is composed of key parts, including a base, worm, and worm gear. With a fully sealed and protective design, the

Read More Get A QuoteEnveloping Slewing Drive SE17

Lyra Drive's SE17 slewing drives are engineered to meet the highest industry standards and are fully customizable to meet specific operational needs. Whether you require enhanced sealing, increased torque, or customized mounting configurations, Lyra Drive has the expertise and resources to provide you with the ideal slewing drive solution for your application.

Read More Get A QuoteEnveloping Slewing Drive SE21

The Enveloping Slewing Drive SE21 series is an advanced integrated transmission component designed to offer robust and reliable performance. It is composed of key parts, including a base, worm, and worm gear. With a fully sealed and protective design, the

Read More Get A QuoteEnveloping Slewing Drive SE25

The Enveloping Slewing Drive SE25 from Lyra Drive offers high torque, precise rotation, and superior durability, making it ideal for demanding applications in harsh environments, with customizable options to meet specific operational needs.

Read More Get A Quote

What is an SE Slew Drive?

An SE slew drive is a fully enclosed gearing system that incorporates a slewing ring bearing, worm shaft, and other mechanical components within a compact housing. This design allows the drive to support high axial, radial, and moment loads while providing rotational movement with high precision. The enclosure ensures that all internal components are protected from dust, debris, and water, making it suitable for outdoor applications.

Key Features of SE Slew Drives

Fully Enclosed System: Protects internal components from environmental contaminants, which is essential for durability and consistent performance in outdoor and harsh environments.

High Load Capacity: SE slew drives are designed to handle high loads efficiently, making them suitable for heavy-duty applications.

Precision Movement: The combination of slewing ring bearings and a precise worm gear setup allows for very accurate positioning capabilities.

Self-Locking: Like many worm gear systems, SE slew drives typically feature a self-locking mechanism that prevents the gear from back-driving, enhancing safety in applications where unintended movement could be hazardous.

Modular Design: Often, SE slew drives are modular, which means they can be customized with various motors (electric, hydraulic, etc.) and can include additional features like encoders for positional feedback, depending on the specific requirements of the application.

Applications of SE Slew Drives

SE slew drives are utilized in a wide array of applications across different sectors due to their robustness and versatility:

Solar Energy Systems: They are extensively used in solar tracking systems to adjust the position of solar panels throughout the day to maximize energy capture.

Wind Turbines: Adjusting the yaw and pitch of wind turbine blades to optimize efficiency and respond to changing wind conditions.

Mobile Cranes and Manlifts: SE slew drives provide the rotational movement required for the operation of cranes and aerial work platforms, handling the substantial loads involved.

Industrial Machinery: Used in turntables, assembly platforms, and other machinery where precise, heavy-load handling is necessary.

Satellite and Communication Dishes: Ensuring precise and stable positioning of communication equipment to maintain optimal alignment for signal reception and transmission.

Selecting an SE Slew Drive

Choosing the right SE slew drive involves several considerations to ensure it meets the specific needs of the application:

Load Requirements: It is crucial to understand both the static and dynamic load requirements the slew drive will need to handle.

Environmental Conditions: The drive should be capable of operating under the specific environmental conditions of the application, such as temperature extremes and potential exposure to corrosive elements.

Precision and Control Requirements: The required precision for rotational movement and any need for feedback systems (like encoders) should be considered.

Size and Space Constraints: The physical space available for the slew drive installation will dictate the size of the drive that can be used.

Integration with Other Systems: Compatibility with existing systems in terms of both mechanical connections and control interfaces is essential for seamless operation.