The SP-H Slew Drive typically stands for a high-load, heavy-duty slew drive configuration, specifically designed to handle very high axial, radial, and moment loads in demanding applications. The "H" in SP-H usually denotes "Heavy" or "High capacity," indicating that these slew drives are engineered for superior performance under extreme conditions.

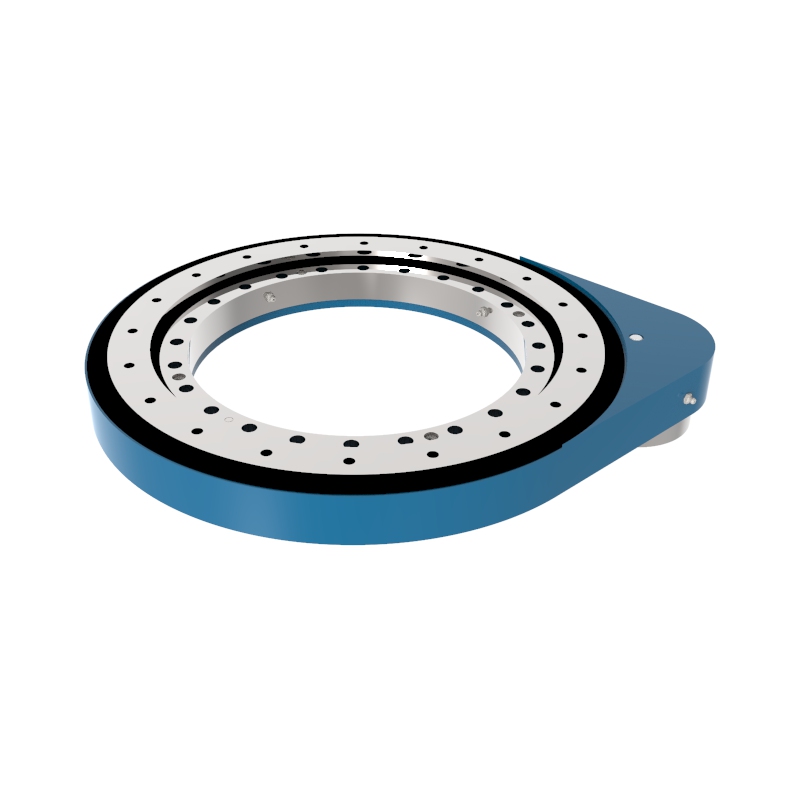

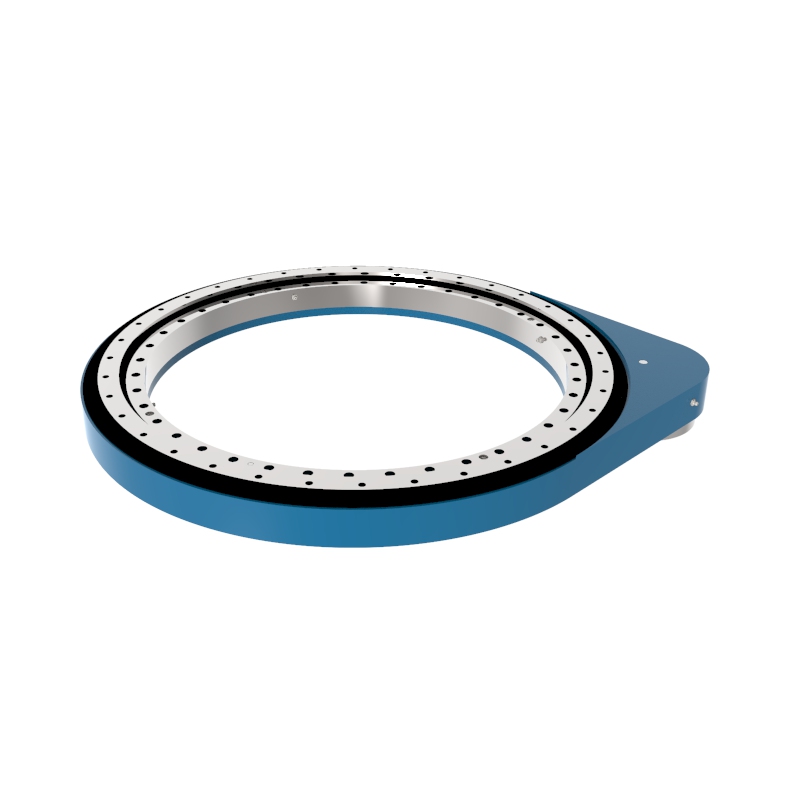

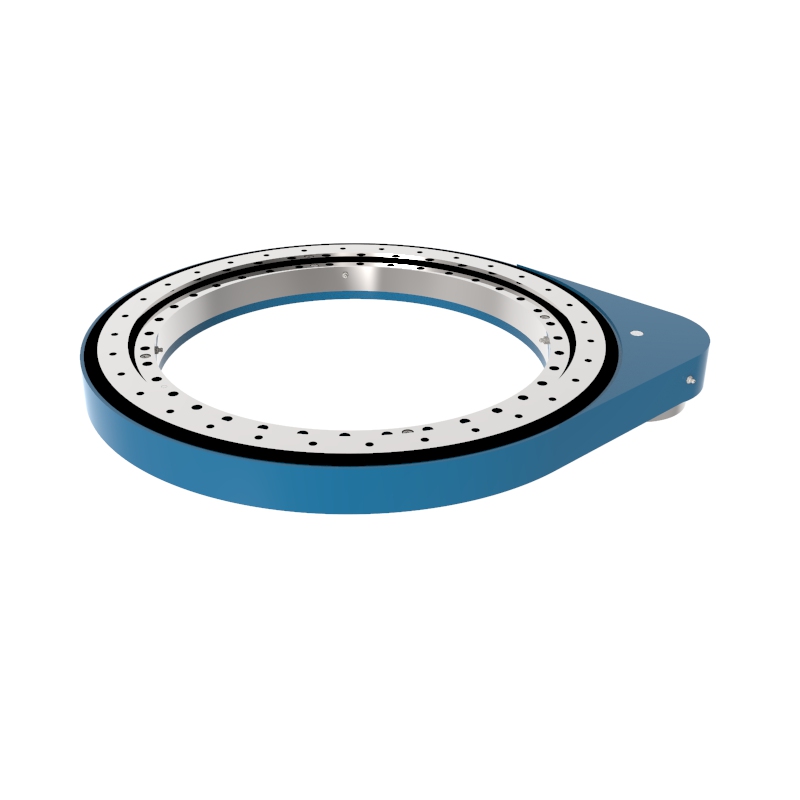

Heavy Duty Gear Slewing Drive SP-H 0455

The SP-H 0455 gear-type slewing drive is a high-efficiency, heavy-duty gear reduction device common

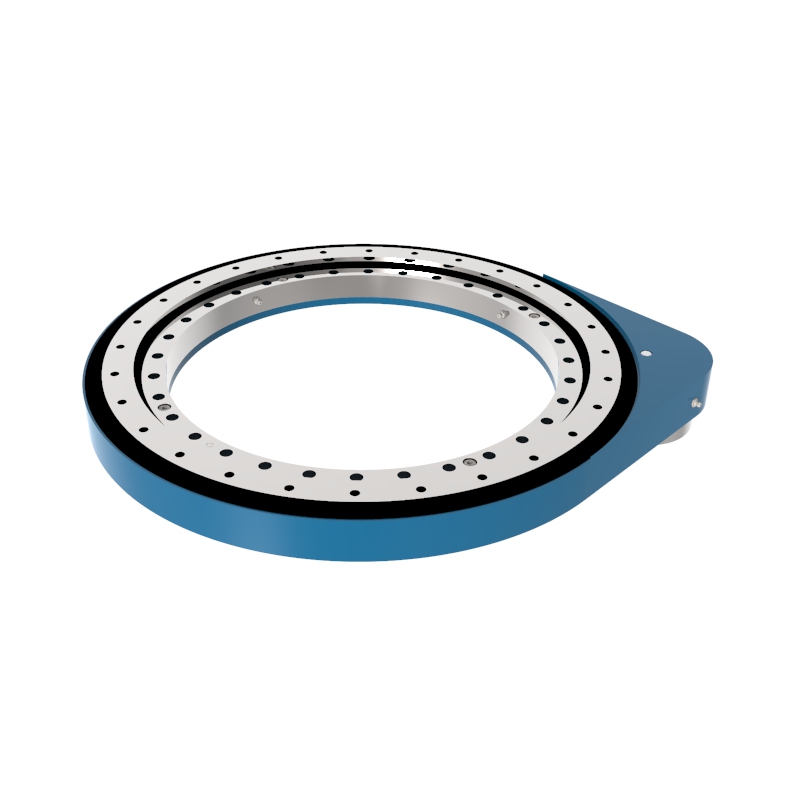

Read More Get A QuoteHeavy Duty Gear Slewing Drive SP-H 0555

SP-H 0555 gear slewing drive is a heavy-duty and efficient gear reduction transmission device, which is widely used in crane slewing and heavy machinery slewing platforms, especially in working conditions that require high precision and have limited insta

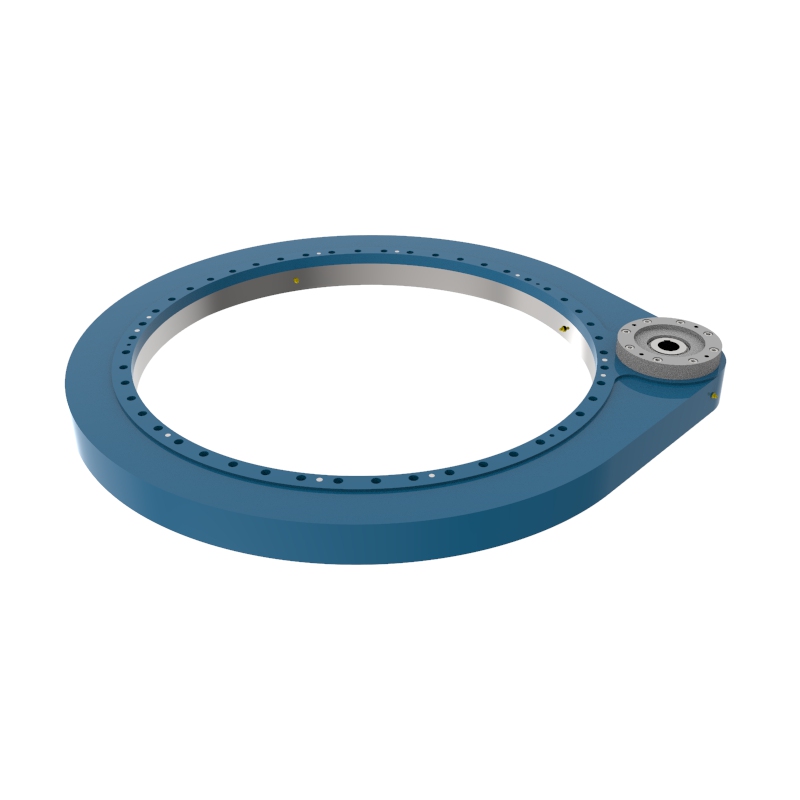

Read More Get A QuoteHeavy Duty Gear Slewing Drive SP-H 0955

SP-H 0955 gear slewing drive is a heavy-duty and efficient gear reduction transmission device, which is widely used in crane slewing and heavy machinery slewing platforms, especially in working conditions that require high precision and have limited insta

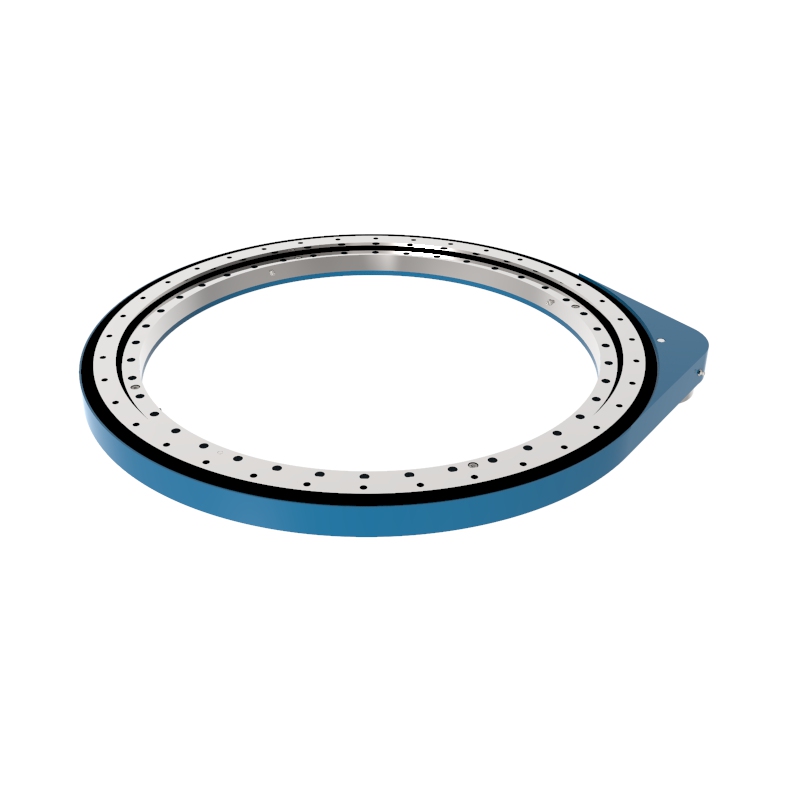

Read More Get A QuoteHeavy Duty Gear Slewing Drive SP-H 0855

SP-H 0855 gear slewing drive is a heavy-duty and efficient gear reduction transmission device, which is widely used in crane slewing and heavy machinery slewing platforms, especially in working conditions that require high precision and have limited insta

Read More Get A QuoteHeavy Duty Gear Slewing Drive SP-H 0755

SP-H 0755 gear slewing drive is a heavy-duty and efficient gear reduction transmission device, which is widely used in crane slewing and heavy machinery slewing platforms, especially in working conditions that require high precision and have limited insta

Read More Get A QuoteHeavy Duty Gear Slewing Drive SP-H 0655

SP-H 0655 gear slewing drive is a heavy-duty and efficient gear reduction transmission device, which is widely used in crane slewing and heavy machinery slewing platforms, especially in working conditions that require high precision and have limited insta

Read More Get A Quote

Design of SP-H Slew Drive

Heavy-Duty Bearings: SP-H slew drives are equipped with robust bearings designed to support higher loads. These bearings may include multiple rows of roller bearings or specialized configurations such as crossed roller bearings for increased load capacity and rotational accuracy.

Strong Gear System: These drives often feature a heavy-duty gear system, which can be either internally or externally mounted. The gears are typically larger and made from high-strength materials to withstand the stresses of heavy loads and provide long service life.

Reinforced Housing: The housing of an SP-H slew drive is built to be extra sturdy to support the heavy internal components and to withstand external environmental conditions like dust, water, and extreme temperatures.

Features of SP-H Slew Drive

Exceptional Load Capacity: Designed to handle significantly higher loads compared to standard or multi-row slew drives.

High Torque Capability: Capable of delivering high torque for powerful rotational movements, essential in heavy machinery.

Durability and Robustness: Built with high-quality materials and protective measures to ensure durability and resistance to wear and tear, even under harsh conditions.

Precision and Stability: Despite their size and strength, SP-H slew drives are designed to maintain precision and stability in movement, crucial for applications requiring accurate positioning.

Customization Options: Manufacturers often provide options to customize gear ratios, motor interfaces, and other specifications to meet specific operational requirements.

Typical Applications of SP-H Slew Drive

Large Construction Machinery: Such as large excavators, tower cranes, and giant wheel loaders which require robust components to handle heavy loads.

Mining Equipment: In heavy-duty drilling rigs and large-scale conveyor systems where high torque and load capacity are necessary.

Marine and Offshore Applications: Including offshore cranes, ship loaders, and deck machinery which must perform reliably in corrosive marine environments.

Wind Turbines: Particularly in larger wind turbines for yaw and pitch control mechanisms, where high load capacity and reliability are critical.

Heavy Industrial Equipment: Used in steel mills, large rotary kilns, and other heavy industrial applications where equipment must support heavy loads continuously.

Selection Considerations for SP-H Slew Drive

Load and Torque Requirements: It is crucial to accurately determine the axial, radial, and moment loads as well as the required torque to ensure the slew drive can handle the application’s demands without failure.

Environmental Conditions: The slew drive must be capable of operating in the specific environmental conditions of the application, which might include extreme temperatures, high levels of dust, or corrosive atmospheres.

Integration with Machinery: Ensure that the slew drive can be integrated seamlessly with other machinery components, particularly with respect to motor and control systems.

Maintenance Accessibility: Given the critical nature and size of these drives, easy access for maintenance and repair is essential to minimize downtime.

Longevity and Reliability: Opt for slew drives from reputable manufacturers known for quality and durability, especially since these components often operate under extreme conditions.