- Precision-crafted slewing bearings, slew drives and gears.

- sales@lyradrive.com

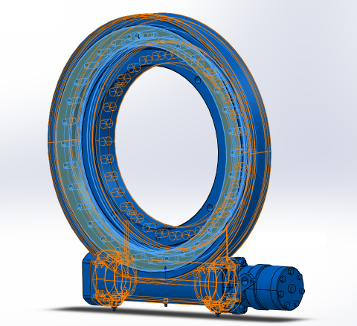

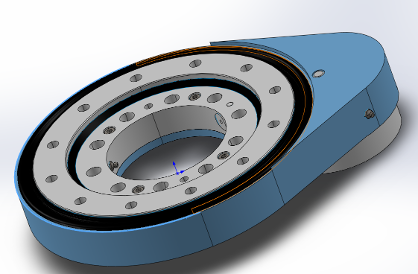

After receiving a user's detailed request, engineers will conduct 3D simulations based on the customer’s requirements and actual operating conditions to verify feasibility. If the design is proven feasible, it will be submitted for production. If not, the design will be optimized until it is feasible.

After the design is proven feasible, the design shall be handed to the manufacturing department for further processing.

Raw Material Procurement and Inspection

The mainstream materials for the rotary drive are divided into three parts:

The housing is generally made of ductile iron. Based on the actual operating conditions, such as temperature, load, and rotational speed, recommended grades include QT450-10, QT500-7, and QT600-3. After casting, the material undergoes heat treatment, metallographic testing, mechanical property testing, and finally, UT testing. Only after passing all inspections can it proceed to the next step of processing.

The raw materials of the rotating part in the worm gear are usually forged with high-quality alloy steel. After high-temperature quenching and tempering (tempering treatment), the material undergoes heat treatment, metallographic, yield strength, tensile, and impact tests, and finally UT testing. After all test items are qualified, it enters the next step of processing.

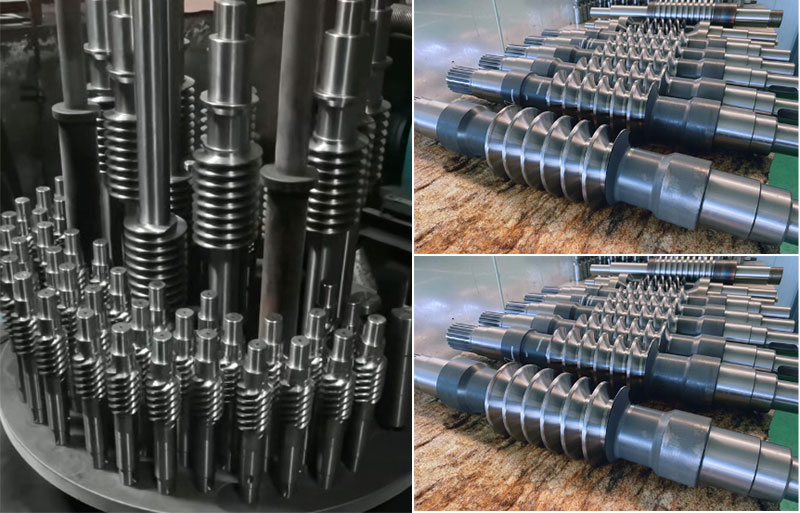

The worm shaft is the main transmission component for power input and is usually made of alloy steel or case-hardened steel. Commonly used materials include 42CrMo, 38CrMoAl, 16Cr5Mn, 20CrMoTi, etc. The alloy steel modulation hardness requirement is HB270-300, and surface hardening is carried out by medium-frequency quenching or gas nitriding. The tooth surface of case-hardened steel is processed after normalizing, followed by carburizing and quenching heat treatment. The hardness can reach HRC58~62, and the depth of the hardened layer is greater than 1.5mm. While improving strength and wear resistance, the toughness of the product is also guaranteed.

Rough Lathe the Finishing of the Gear Ring

Forged blanks that have passed inspection are machined according to the detailed part drawing. A post-processing allowance of 0.5-2.5mm is allowed for deformation and machining based on the desired diameter, height, and wall thickness of the finished product.

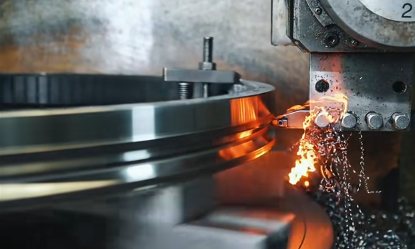

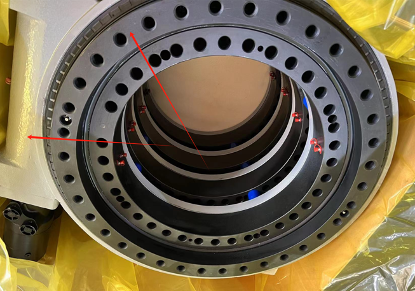

Medium-frequency quenching of the raceways

Using a medium-frequency quenching machine, the raceway surface hardness is increased to HRC55-60. Depending on the rolling element diameter, the hardened layer depth can reach 1-5mm, ensuring the product's load-bearing strength and wear resistance without compromising its toughness.

Finishing and Processing of Products: Surface quenching releases internal stresses in the product, which can cause deformation. The excess material left over from initial machining can be re-finished to meet the drawing requirements. The surface roughness of the finished product can be reduced to 0.8 to 3.2 mm.

Surface Treatment: Both the housing and the rotating worm gear require surface anti-corrosion treatment after installation. The housing is typically painted or plastic-sprayed, achieving a maximum protection level of C5H. The worm gear is typically treated with QPQ (salt bath composite technology), which effectively improves the metal surface's wear and corrosion resistance.

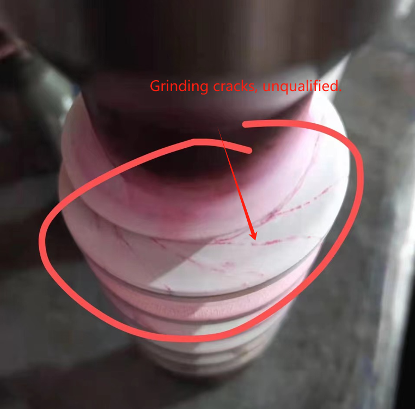

Tooth Profile Grinding Test: After processing the worm gear and worm, a tooth profile meshing test is required to verify the matching and ensure that the product meets the technical design requirements.

Part Inspection: After all parts are processed and assembled, they must be individually inspected according to the part drawings. Parts that have undergone heat treatment and grinding must undergo flaw detection before entering the assembly workshop.

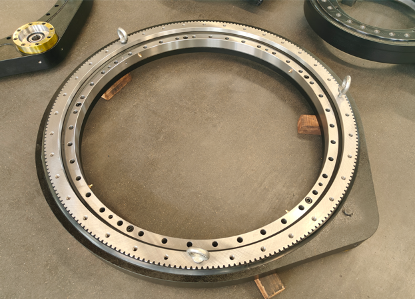

After assembling the finished product, it is necessary to check and compare the finished product size one by one according to the drawing to ensure that it is within the drawing tolerance before delivery.

Input end internal diameter micrometer inspection

Input keyway inspection

Install threaded hole plug gauge inspection

Mounting hole center distance detection

Slew Drive Assembly

After the product is tested according to the drawings, a finished product test report will be issued, and the product will be cleaned, packed, and shipped.