A slew drive is a ready-to-install unit consisting of a ball or roller slewing ring bearing, drive gear, housing, and possibly a motor. It is designed to handle radial, axial, and moment loads, providing rotational motion and power transmission in a compact module. Slew drives are used to control rotational movement with precision and can support heavy loads while maintaining stability.

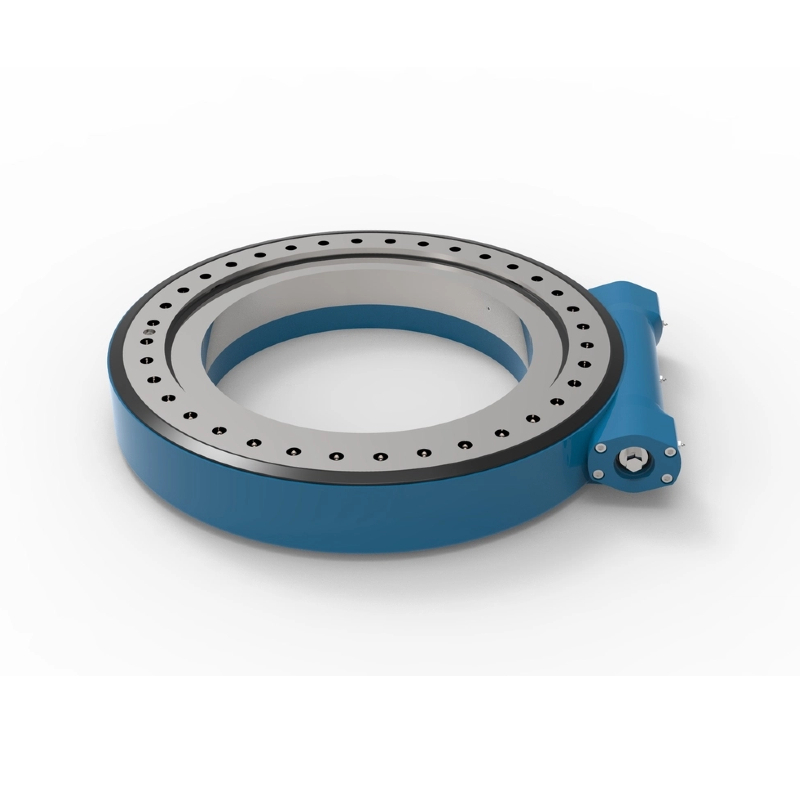

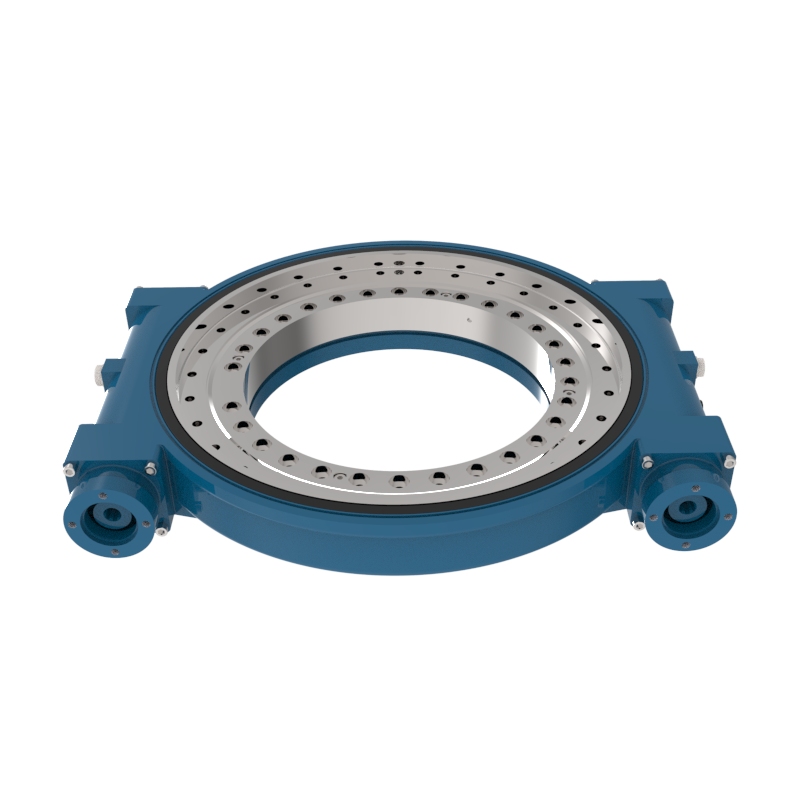

Worm Gear Drive WE25

The Worm Gear Drive WE25 is a high-precision, dustproof, and waterproof rotary drive system designed for heavy-duty applications like marine cranes and lifting equipment, offering impressive output torque, self-locking safety features, and versatility for various industrial uses.

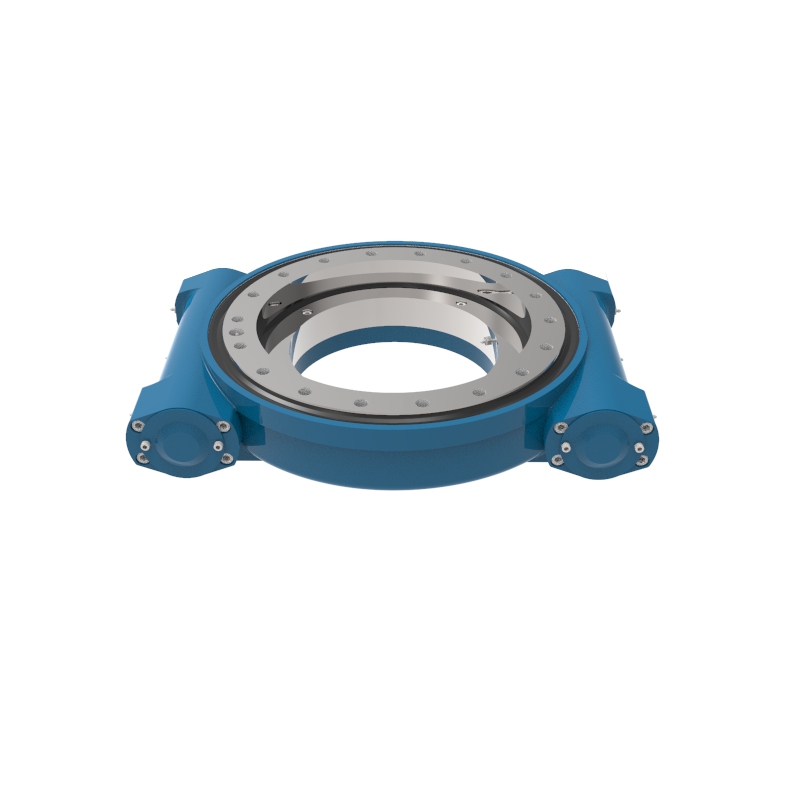

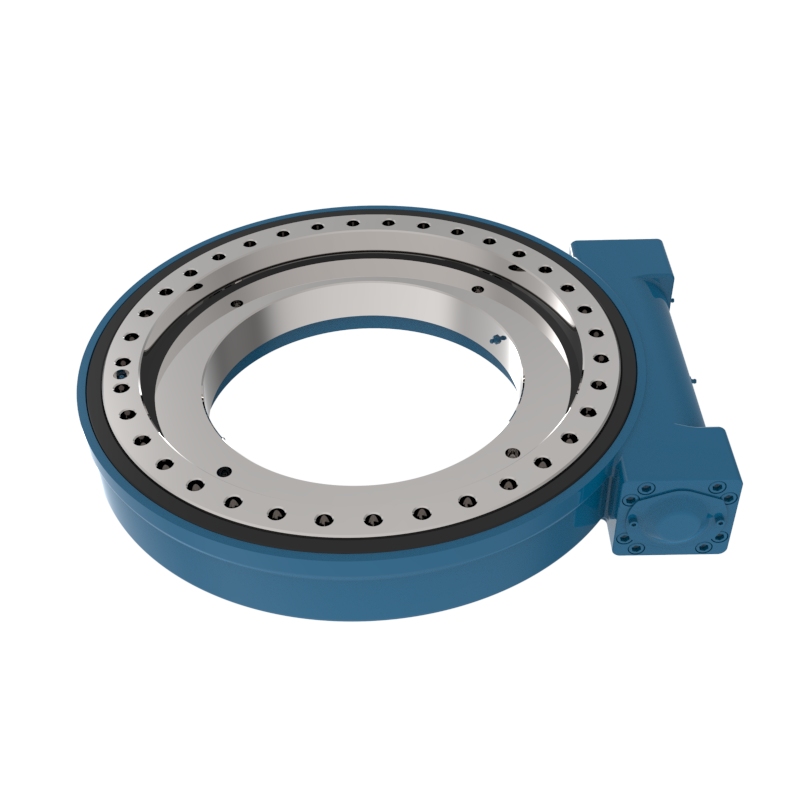

Read More Get A QuoteOpen Housing Slew Drive S14

Open Housing Slew Drive S14 is an advanced integrated modular transmission component designed to facilitate efficient rotary motion across various applications.

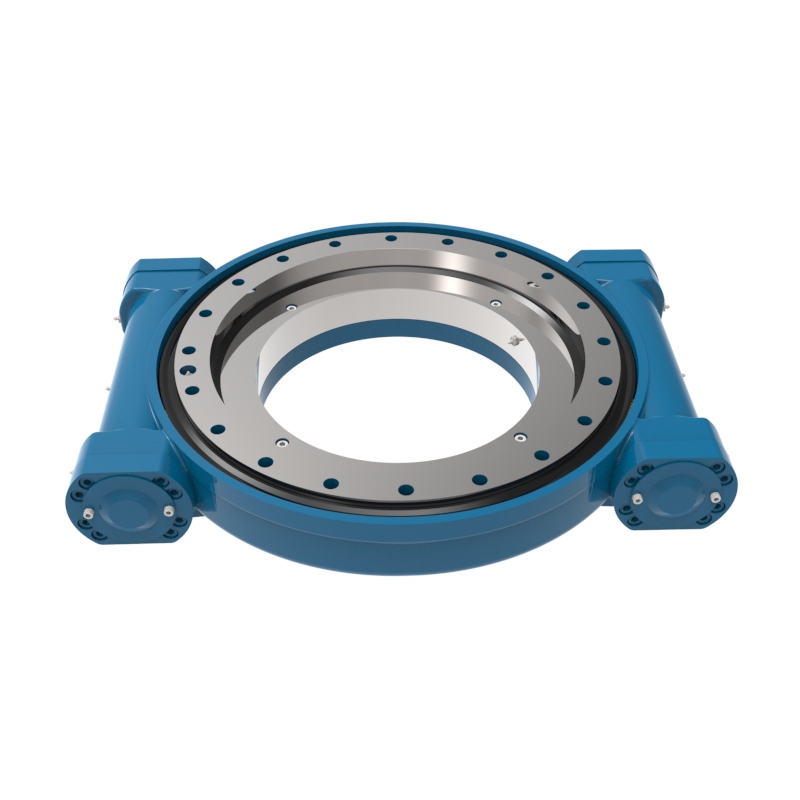

Read More Get A QuoteOpen Housing Slew Drive S17

The Open Housing Slew Drive S17 is a versatile and lightweight integrated transmission component designed for high-performance rotary applications, featuring self-locking functionality and enhanced torque capacity, making it ideal for use in aerial work platforms, mobile cranes, and industrial machinery, with ordering facilitated through Lyra Drive, a trusted manufacturer.

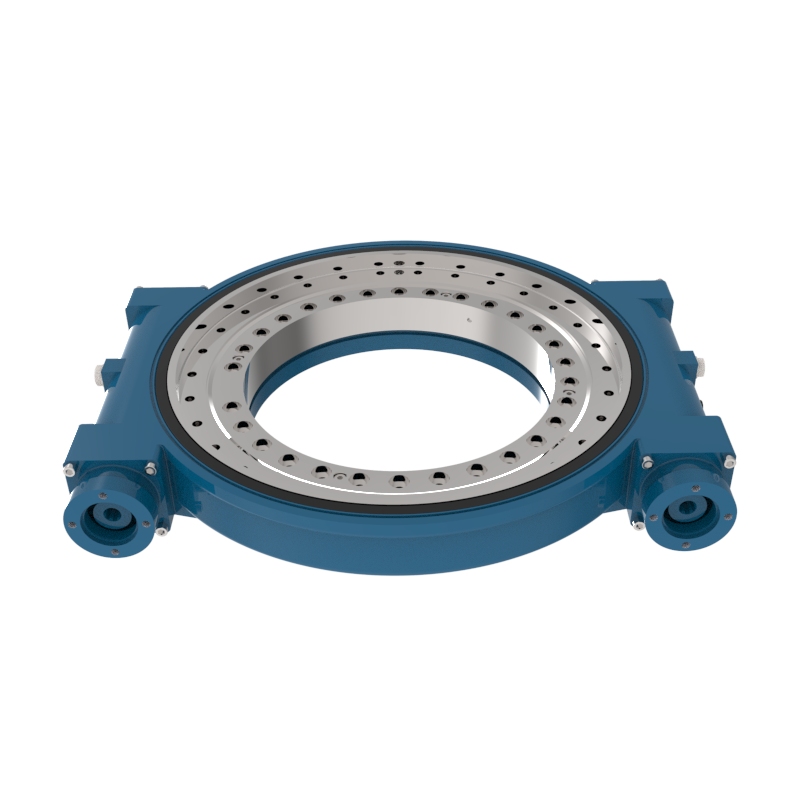

Read More Get A QuoteOpen Housing Slew Drive S19

The Open Housing Slew Drive S19 is a lightweight, reliable rotary drive designed for various applications, featuring a self-locking mechanism, enhanced torque capabilities, and built for efficiency in industries like construction and mobile cranes.

Read More Get A QuoteDouble Worm Slewing Drive WED14

The Double Worm Slewing Drive WED14 is a high-performance, self-locking transmission unit that enhances torque, load capacity, and safety for heavy-duty applications, with customization options available to suit specific industry needs.

Read More Get A QuoteDouble Worm Slewing Drive WED17

The Double Worm Slewing Drive WED17 is a high-performance, compact rotational drive system designed for heavy-duty applications, offering high torque, self-locking functionality, and excellent durability in harsh environments, with customizable options to meet specific operational needs.

Read More Get A QuoteDouble Worm Slewing Drive WED21

Output Torque:48kN.mTilting Moment Torque:203kN.mHolding Torque:179.8kN.mGear Ratio:90:1Tracking Precision:≤0.13°

Read More Get A QuoteDouble Worm Slewing Drive WED 25

The Double Worm Slewing Drive WED25 is a high-performance, heavy-duty mechanical component designed to deliver superior rotational motion for large-scale industrial machinery. It is an advanced slewing drive that incorporates two worms driving a single worm wheel, providing higher output and holding torque than traditional slewing drives. The WED25 is specifically engineered to handle heavy loads and extreme operational environments, offering enhanced precision, reliability, and safety in a comp

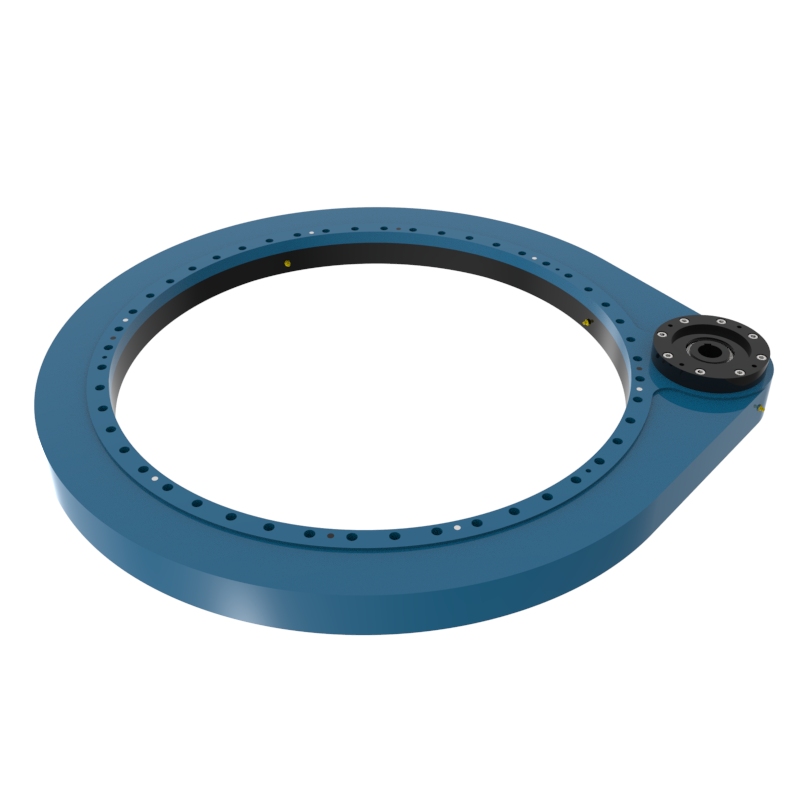

Read More Get A QuoteOpen Housing Slew Drive S9

The Open Housing Slew Drive S9 is a lightweight, high-performance rotary drive designed for applications like aerial work platforms and cranes, featuring self-locking capabilities and enhanced torque handling, making it a reliable choice for various industrial uses.

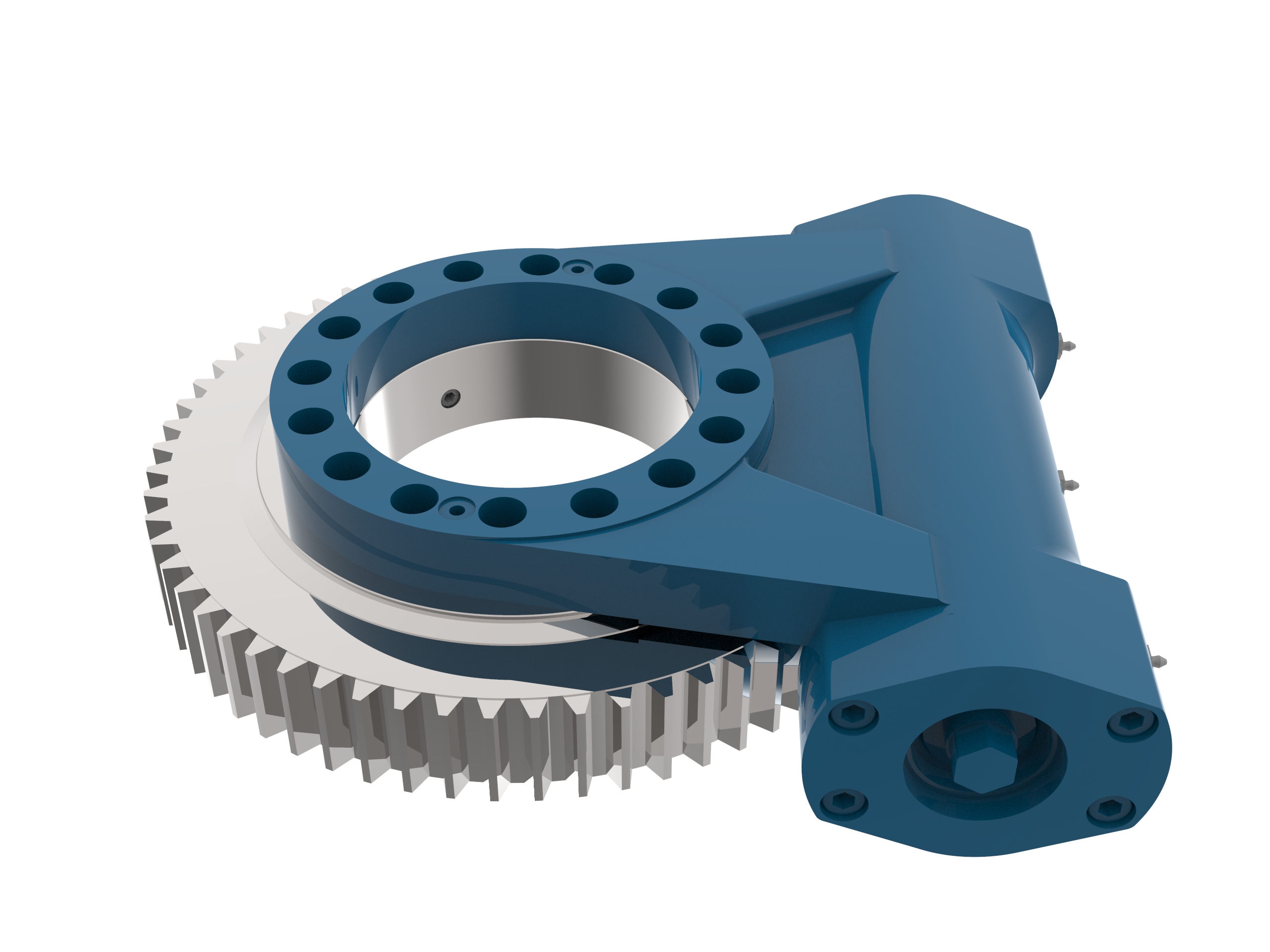

Read More Get A QuoteLightweight Slewing Ring Gear Drive SP-I 0941

SP-I 0941 gear slewing drive is a highly efficient gear reduction transmission device, which is widely used in the automatic slewing of industrial machinery, especially in the occasions that require high precision and high speed.

Read More Get A QuoteWorm Gear Drive WE21

The Worm Gear Drive WE21 is an advanced, integrated rotary drive system designed for a wide range of industrial applications. Composed of key components such as a base, worm shaft, and worm wheel, the WE21 is engineered to operate efficiently within a sealed environment. This drive system can handle axial loads, radial forces, and overturning moments simultaneously, while its self-locking mechanism ensures secure operation even when power is lost. This makes the WE21 particularly suitable for ap

Read More Get A Quote

Types of Slew Drive

Slew drives are primarily categorized based on the type of gears and motors used:

Worm Gear Slew Drives:

These use a worm (a type of gear resembling a screw) to engage with a wheel, providing high torque at low speeds. They are inherently self-locking, making them ideal for applications requiring load holding.

Spur Gear Slew Drives:

These involve spur gears, which are straight-toothed gears. They offer high efficiency and are suitable for applications requiring high speed and lower torque compared to worm gear drives.

Helical Gear Slew Drives:

Similar to spur gears but with angled teeth, helical gears engage more gradually, offering smoother and quieter operation. They are used where noise reduction is critical.

Bevel Gear Slew Drives:

These drives use bevel gears that allow transmission of power between axes that are not parallel. They are typically used in applications requiring the transfer of motion at an angle.

Features of Slew Drive

High Load Capacity: Designed to support heavy axial, radial, and moment loads.

Compact Design: Integrates bearings and gears into a single unit, saving space and simplifying installation.

Precision: Provides accurate control of rotational movement, crucial for applications requiring precise positioning.

Versatility: Available in various configurations to suit different applications and load requirements.

Ease of Maintenance: Typically designed for long life with minimal maintenance requirements.

Customizability: Can be tailored with different motors, encoders, and other modifications to meet specific requirements.

Applications of Slew Drive

Slew drives are used in a wide range of applications across various industries:

Solar Power Systems: For tracking the sun in photovoltaic and concentrated solar power systems.

Wind Turbines: Used in the yaw and pitch adjustment mechanisms.

Cranes and Manlifts: To achieve precise positioning of the boom and basket.

Satellite and Communication Dishes: For accurate positioning to ensure optimal signal reception.

Construction Equipment: In excavators, backhoes, and other heavy machinery for rotation and handling.

Industrial Turntables: To rotate stages, platforms, or heavy loads smoothly.

How to Select Slew Drive?

Selecting the right slew drive involves several considerations:

Load Capacity: Evaluate the maximum loads (axial, radial, and moment) the drive will need to handle.

Operational Speed: Consider the required operational speed and match it with the appropriate gear type.

Precision Requirements: Determine the precision level needed for the application, especially in terms of rotational accuracy and backlash.

Environmental Conditions: Assess the environmental conditions such as temperature, moisture, dust, and potential corrosive elements the drive will be exposed to.

Integration Needs: Ensure the slew drive can be integrated into the existing system with appropriate mounting and connection interfaces.

Power Source: Decide on the type of motor or manual operation required based on the application's power availability and control needs.

Budget and Cost-Effectiveness: Balance the performance requirements with the budget, considering not only initial cost but also maintenance and operational costs.