What is Worm Gear Slew Drive?

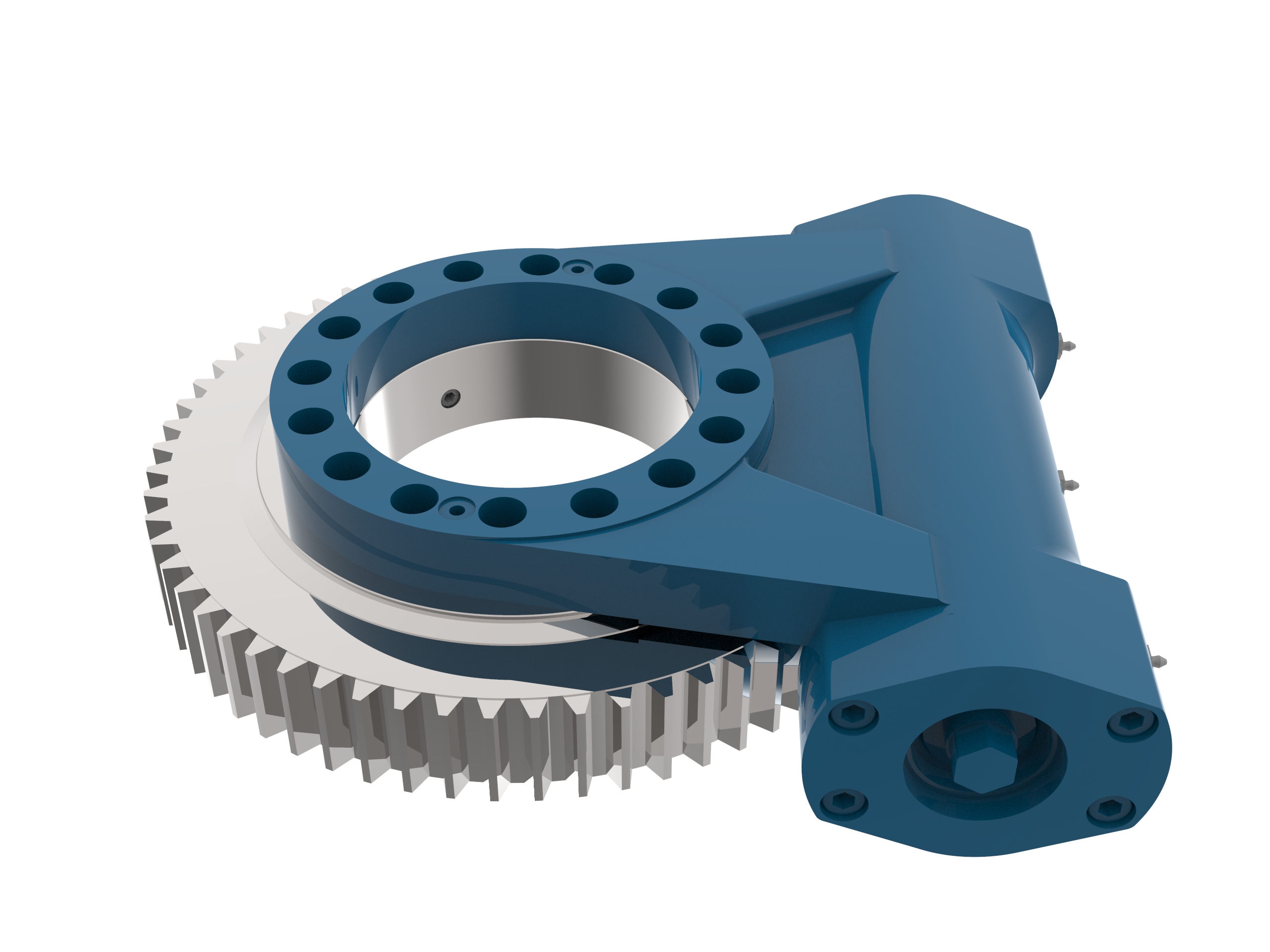

A worm gear slew drive is a compact, self-contained gearing system that combines a worm shaft (the input) with a worm wheel (the output). This setup allows for high torque and low-speed applications, typically used for precise rotational movement control. The design inherently provides a large reduction ratio in a single stage, and the worm gear's engagement ensures that the system can hold loads without back-driving, making it ideal for applications requiring positional accuracy and stability.

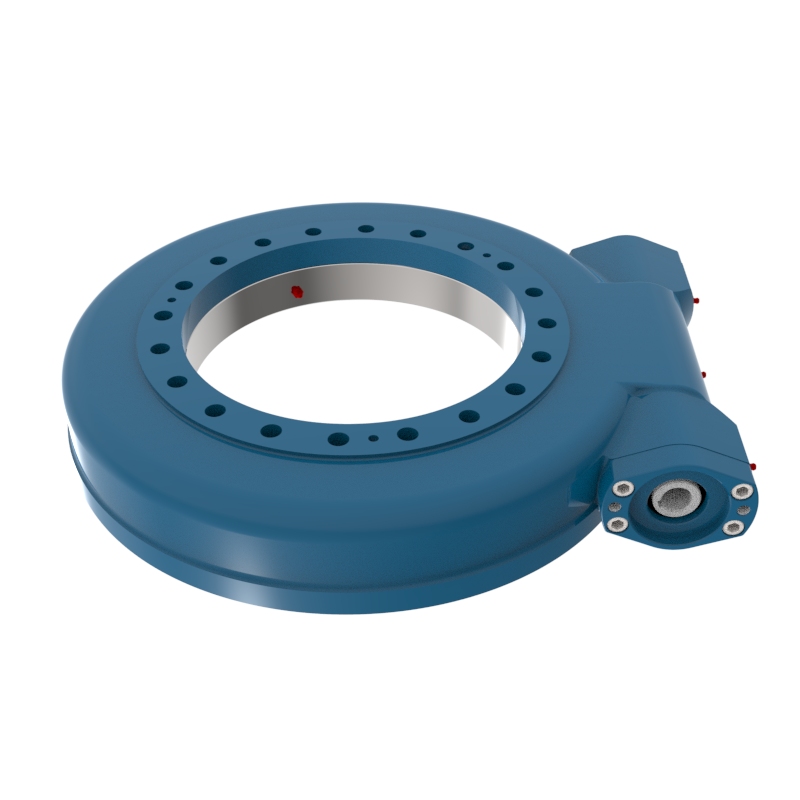

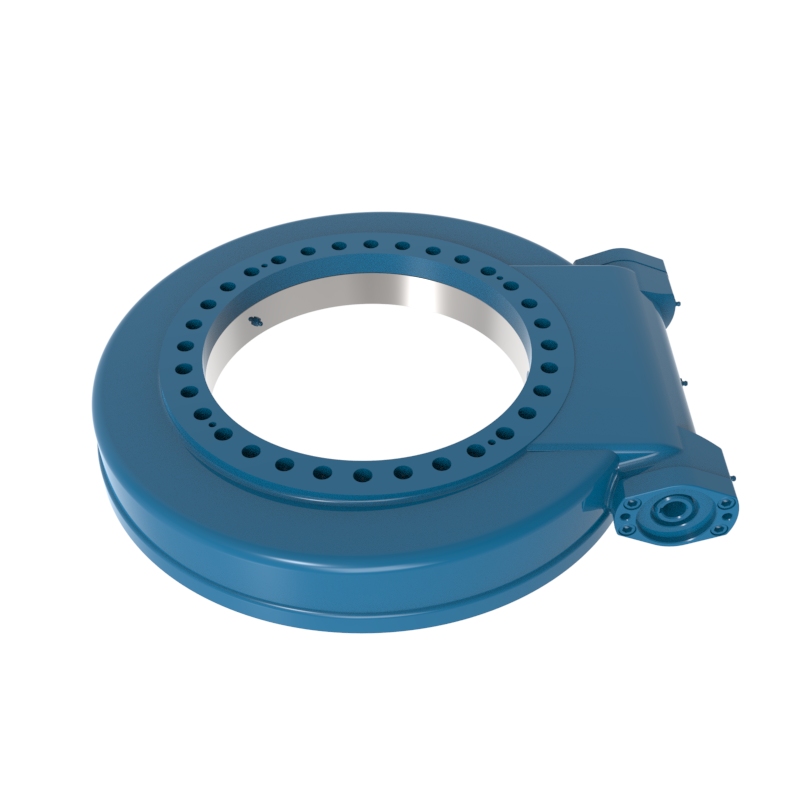

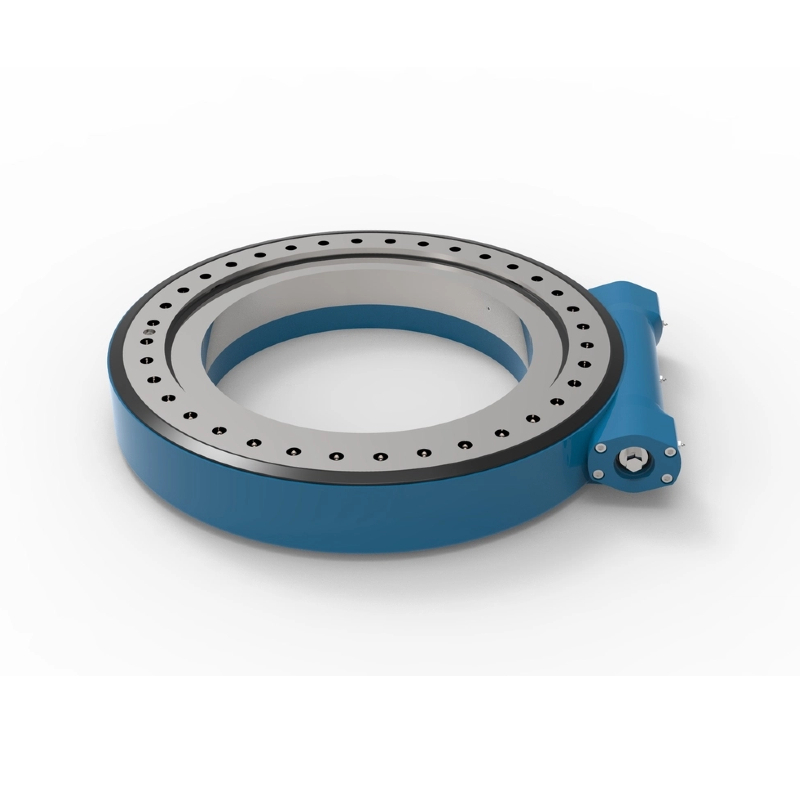

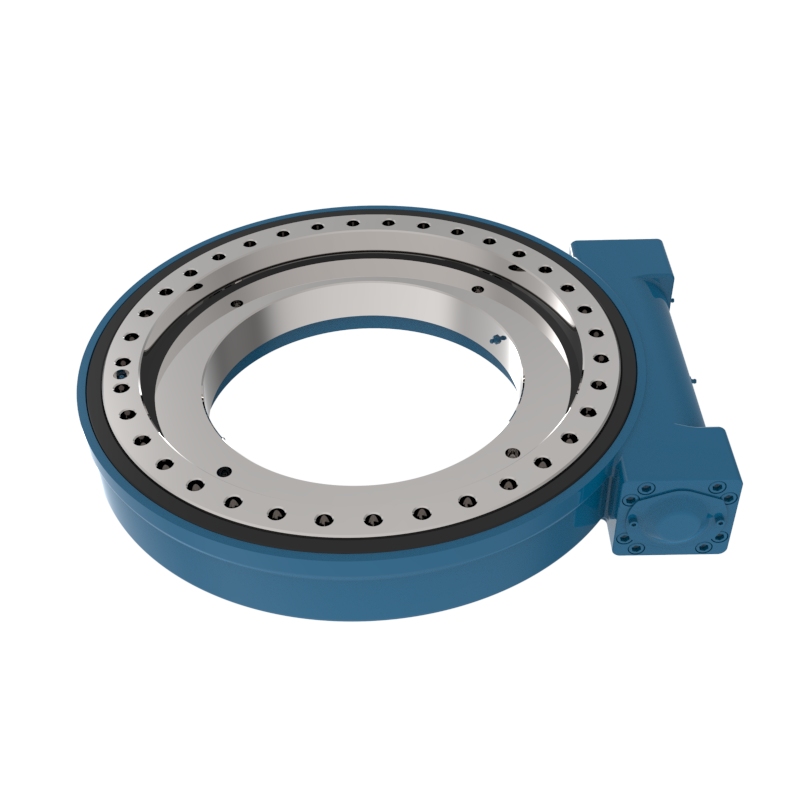

Worm Gear Drive WE17

Worm Gear Drive WE17 is a sophisticated drive component designed for various industrial applications. Comprising a sturdy base, a precisely engineered worm shaft, and a corresponding worm wheel, the WE17 is built to operate effectively in closed protectiv

Read More Get A QuoteWorm Gear Drive WE19

Worm Gear Drive WE19 is an integrated drive component designed to handle axial loads, radial forces, and overturning moments, featuring a self-locking mechanism and high efficiency for various industrial applications.

Read More Get A QuoteWorm Gear Drive WE25

The Worm Gear Drive WE25 is a high-precision, dustproof, and waterproof rotary drive system designed for heavy-duty applications like marine cranes and lifting equipment, offering impressive output torque, self-locking safety features, and versatility for various industrial uses.

Read More Get A QuoteOpen Housing Slew Drive S14

Open Housing Slew Drive S14 is an advanced integrated modular transmission component designed to facilitate efficient rotary motion across various applications.

Read More Get A QuoteOpen Housing Slew Drive S17

The Open Housing Slew Drive S17 is a versatile and lightweight integrated transmission component designed for high-performance rotary applications, featuring self-locking functionality and enhanced torque capacity, making it ideal for use in aerial work platforms, mobile cranes, and industrial machinery, with ordering facilitated through Lyra Drive, a trusted manufacturer.

Read More Get A QuoteOpen Housing Slew Drive S19

The Open Housing Slew Drive S19 is a lightweight, reliable rotary drive designed for various applications, featuring a self-locking mechanism, enhanced torque capabilities, and built for efficiency in industries like construction and mobile cranes.

Read More Get A QuoteOpen Housing Slew Drive S9

The Open Housing Slew Drive S9 is a lightweight, high-performance rotary drive designed for applications like aerial work platforms and cranes, featuring self-locking capabilities and enhanced torque handling, making it a reliable choice for various industrial uses.

Read More Get A QuoteWorm Gear Drive WE21

The Worm Gear Drive WE21 is an advanced, integrated rotary drive system designed for a wide range of industrial applications. Composed of key components such as a base, worm shaft, and worm wheel, the WE21 is engineered to operate efficiently within a sealed environment. This drive system can handle axial loads, radial forces, and overturning moments simultaneously, while its self-locking mechanism ensures secure operation even when power is lost. This makes the WE21 particularly suitable for ap

Read More Get A Quote

Types of Worm Gear Slew Drive

There are primarily two types of worm gear slew drives:

Single-Start Worm Gear Slew Drive:

This type has a single thread on the worm shaft. It offers smoother and more precise movements but with a lower efficiency and speed. It is typically used where precision is more critical than speed.

Multiple-Start Worm Gear Slew Drive:

This type features multiple threads on the worm shaft, allowing for higher efficiency and faster operation. It is suitable for applications where speed is necessary, and precise control is less critical.

Features of Worm Gear Slew Drive

High Torque Capacity: Capable of handling high loads with a compact footprint.

Self-locking Ability: Naturally prevents back-driving, which is crucial for holding loads in place without additional braking mechanisms.

Precision: Offers high positional accuracy, making it suitable for operations requiring meticulous control.

Durability: Designed to be robust and durable, often featuring weatherproof and corrosion-resistant materials.

Compactness: Integrates gearing, bearing, and base into a single unit, saving space and simplifying installation.

Applications of Worm Gear Slew Drive

Worm gear slew drives are used in a variety of applications, including:

Solar Trackers: To adjust panels to follow the sun’s movement throughout the day.

Wind Turbines: For yaw and pitch control.

Satellite and Radar Dishes: To precisely position antennas.

Cranes and Lifts: In the mechanisms that require precise handling.

Robotic Arms: Providing rotational movement with high precision and load capacity.

Heavy Equipment: Such as excavators and backhoes, where controlled rotational movement is necessary.

How to Select Worm Gear Slew Drive?

Selecting the right worm gear slew drive involves considering several factors:

Load Requirements: Assess the maximum load the drive must handle, both in terms of torque and axial/radial loads.

Speed and Efficiency: Determine the necessary operational speed and the acceptable efficiency level.

Precision and Backlash: Consider the required precision and acceptable backlash, especially important in applications like robotics or satellite dish positioning.

Environment: Account for environmental conditions such as temperature, exposure to elements, and potential contaminants.

Size and Space Constraints: Ensure the selected slew drive fits within the available space and integrates well with the overall system design.

Material and Coatings: Choose materials and coatings that offer the required durability and corrosion resistance.

Cost: Balance all technical requirements with budget constraints to find a cost-effective solution.

Worm Gear Slew Drive Installation and Operation Manual

Important Notice:

Read this manual thoroughly before installing or operating the Worm Gear Slew Drive.

Contains vital safety and operational information

Installation must be performed by certified technicians

Contact technical support for any clarification

1. Transportation, Handling and Storage

1.1. Transportation and Handling Procedures

Transport in original packaging with proper orientation markings facing upward

Use certified lifting equipment with minimum 4 attachment points

Never lift using motor shafts or external components

Maintain ambient temperature between -20°C to 50°C during transit

1.2. Storage Guidelines

Indoor storage preferred in climate-controlled environment

Relative humidity must not exceed 70%

Rotate drive 90° every 3 months if stored long-term

Preservative coating effective for 12 months in unopened packaging

2. Installation and Maintenance

2.1. Pre-Installation Checklist

✔ Verify drive model matches specifications

✔ Inspect for shipping damage (check seals, housings, shafts)

✔ Confirm all mounting surfaces within 0.1mm flatness tolerance

✔ Prepare appropriate tools and lifting equipment

2.2. Surface Preparation

Degrease using isopropyl alcohol (90% concentration minimum)

Remove all oxidation using non-metallic abrasives

Apply thin layer of anti-seize compound (nickel-based recommended)

Protect sealing surfaces with temporary covers during preparation

2.3. Fastener Specifications

Critical Requirements:

Metric coarse thread series (ISO 898-1 compliant)

Minimum property class 10.9 for all structural connections

Thread engagement = 1.5 × nominal diameter (minimum)

Prevailing torque locknuts required for all vertical applications

2.4. Torque Values and Tightening Sequence

Recommended Installation Torques (Dry):

| Bolt Size | Initial Torque (Nm) | Final Torque (Nm) | Angle Tightening (°) |

|---|---|---|---|

| M12 | 60 | 120 | 90 |

| M16 | 150 | 300 | 120 |

| M20 | 300 | 600 | 180 |

| M24 | 520 | 1040 | 270 |

Tightening Pattern:

Follow crisscross sequence starting from center bolts moving outward

2.5. Installation Procedure

Align drive within 0.05mm/m tolerance using laser alignment tools

Install temporary locating pins for precise positioning

Apply threadlocker (medium strength, anaerobic type)

Perform three-stage tightening sequence:

30% torque to seat components

70% torque for preliminary tension

100% torque + angle tightening

Verify backlash (0.08-0.12mm typical for new units)

2.6. Lubrication Requirements

Initial Lubrication Specifications:

Primary gear: Mobil SHC 460 (or equivalent synthetic)

Bearings: Kluber Staburags NBU 30/600

Seals: Molykote 111 silicone paste

Fill Quantities:

Gear chamber: 80% of free volume

Bearing cavities: 30-40% fill ratio

2.7. Maintenance Schedule

Standard Operating Conditions:

| Parameter | Interval | Action Required |

|---|---|---|

| Visual Inspection | Weekly | Check for leaks, unusual noise |

| Lubricant Analysis | Quarterly | Send sample to lab |

| Backlash Measurement | Biannually | Record wear patterns |

| Complete Overhaul | 20,000 hours | Full disassembly inspection |

Severe Service Conditions:

Reduce all intervals by 50% for:

Continuous operation (>16hr/day)

High shock loading applications

Marine/offshore environments

3. Operational Guidelines

Break-in Procedure (First 100 Hours):

Limit to 50% rated load

Operate through full rotation every 2 hours

Monitor temperature (≤85°C surface temp)

Check lubrication after first 24 hours

Troubleshooting Guide:

| Symptom | Likely Cause | Corrective Action |

|---|---|---|

| Excessive noise | Lubrication failure | Immediate relubrication |

| Overheating | Misalignment | Laser alignment check |

| Irregular motion | Backlash increase | Adjust preload or replace gear |

| Oil leakage | Seal degradation | Replace all shaft seals |

4. Safety Protocols

Lockout/Tagout procedures mandatory for maintenance

Thermal monitoring required for continuous duty cycles

Personal protective equipment including:

Cut-resistant gloves

Safety goggles

Steel-toe footwear

Warning:

Never exceed maximum rated parameters:

120% peak torque (intermittent)

100% continuous torque

15 rpm maximum input speed

For technical drawings, CAD models, or additional documentation, visit our engineering portal at [website] or contact our 24/7 technical support hotline.

Revision History:

[Date] - Initial release

[Date] - Updated torque specifications

[Date] - Added severe service guidelines

This manual meets ISO 9001:2015 quality standards and complies with relevant CE directives. Specifications subject to change without notice.