Unstoppable Rotation: Double Row Ball & Three Row Roller Bearings Powering Industry

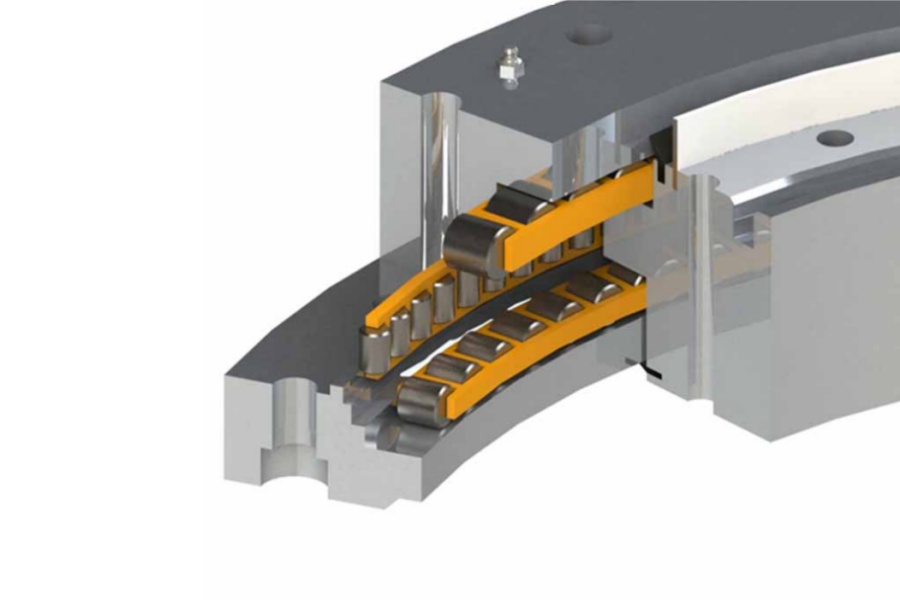

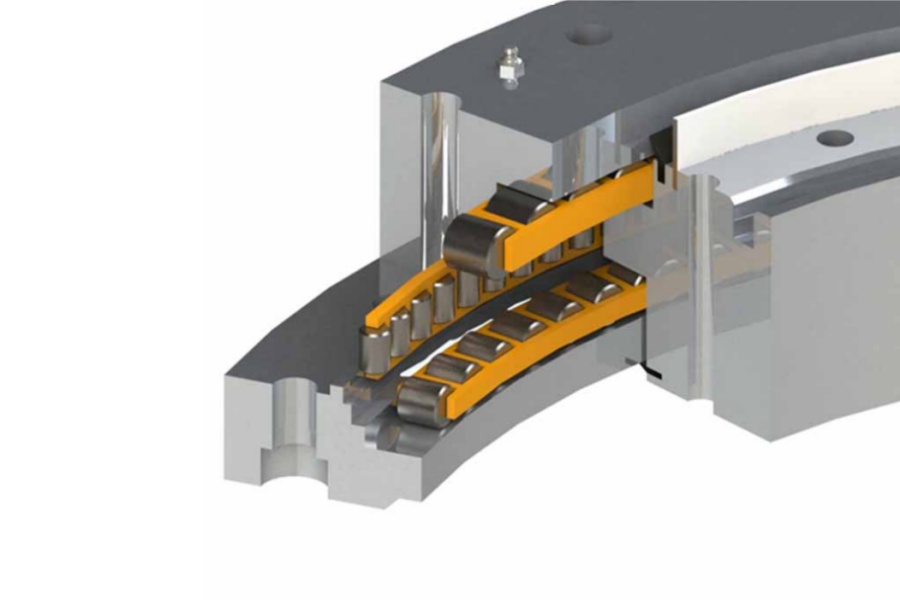

What is a Three Row Roller Slewing Bearing?

A three row roller slewing bearing is the ultimate solution for extreme loads. It uses three distinct roller paths: one row manages axial loads in one direction, another row handles axial loads in the opposite direction, and a dedicated radial row supports heavy radial loads and tilting moments. This separation allows unmatched load distribution and capacity. Rollers provide larger contact areas than balls, enabling immense load handling with superior rigidity and minimal deformation – critical for the most demanding applications.

Slewing Bearing for Wind Turbine

Wind turbines rely heavily on slewing bearings. Yaw bearings rotate the nacelle to face the wind, enduring massive axial loads, moments, and harsh environments. Pitch bearings precisely adjust blade angles, handling complex cyclic loads for power control and safety. Both demand exceptional materials, sealing, and longevity (20+ years) against elements like salt spray and temperature extremes.

Slewing Bearing for Mining Equipment

Mining equipment operates in brutal conditions. Giant excavators, draglines, stackers, and reclaimers depend on robust slewing bearings (often three-row rollers) for 360-degree rotation. These bearings withstand colossal weights, extreme dynamic loads (digging, swinging), abrasive dust, moisture, and severe impacts. Reliability is paramount to avoid catastrophic downtime, demanding supreme wear resistance, sealing, and shock load capacity.

Key Features of Three Row Roller Bearings

Unmatched Load Capacity: Handles extreme axial (both ways), radial loads, and tilting moments simultaneously.

Superior Rigidity: Minimal deformation under load ensures precision and stability.

Optimized Load Distribution: Dedicated paths for each load type maximize life.

Exceptional Moment Resistance: Crucial for high centers of gravity.

Robust Durability: Built for severe environments with high-grade materials and hardening.

High Reliability: Predictable performance in critical applications.

Applications of Three Row Roller Bearings

Heavy Cranes (Tower, Mobile, Crawler)

Mining Excavators & Draglines

Port Cranes (STS, RMG)

Stackers & Reclaimers

Large Offshore Wind Turbine Main Bearings

Ladle Turrets (Steel)

Tunnel Boring Machines (TBMs)

Large Radars & Defense Systems

Price Factors for Three Row Roller Bearings

Size & Dimensions: Diameter is a major cost driver.

Load Capacity & Design: Higher loads/custom designs cost more.

Material: Quantity and quality (high-alloy steel) significantly impact price.

Precision & Tolerances: Tighter specs increase machining costs.

Heat Treatment: Deep, controlled raceway hardening is essential and costly.

Gearing: Integrated gear teeth add substantial expense.

Sealing: Advanced, multi-lip, or corrosion-resistant seals cost more.

Lubrication: Integrated systems add complexity.

Surface Protection: Special coatings (e.g., Dacromet) increase cost.

Quality Control & Certs: Rigorous NDT, testing, and documentation add overhead.

Quantity & Customization: Volume discounts vs. one-off engineering costs.

Selecting a Supplier: Engineering Excellence Matters

Choosing a supplier for critical three row roller bearings demands more than price comparison. Prioritize proven engineering expertise in your application, robust manufacturing capabilities (CNC, heat treatment, QA), guaranteed material quality, and customization ability. Look for a strong track record in heavy industry, comprehensive technical support, and global service.

Supplier of Three Row Roller Slewing Bearings

For Double Row Ball and especially high-performance Three Row Roller Slewing Bearings, LYRADRIVE delivers engineered reliability. We specialize in bearings for mining, wind, construction, and material handling. Using premium steel, precision CNC machining, and advanced heat treatment, we ensure durability. LYRADRIVE excels in customization, designing bearings for your exact loads, environment, and space constraints. Our engineering support includes load analysis, FEM verification, installation guidance, and maintenance planning. Trust LYRADRIVE for bearings engineered to maximize uptime and safety in the world's toughest applications.