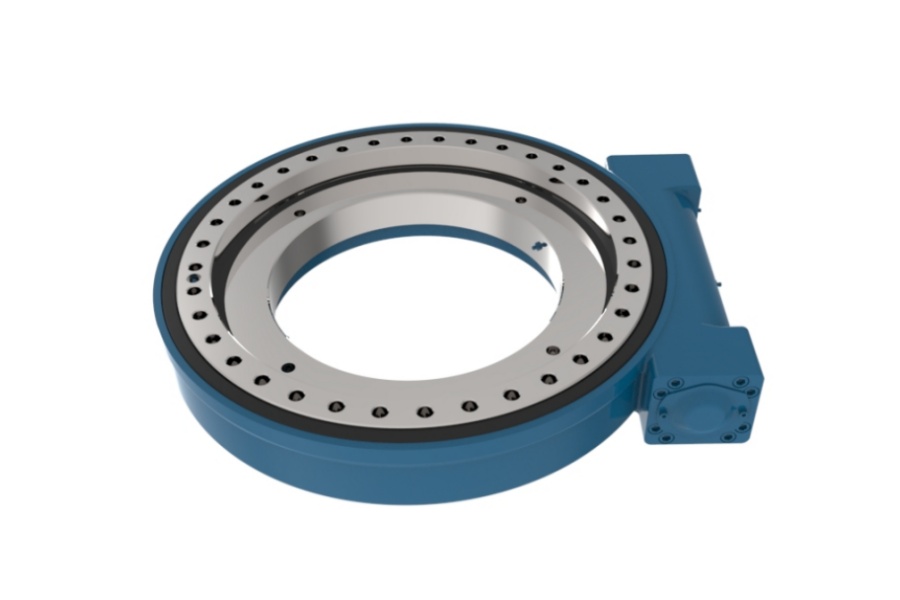

Worm Gear Drive WE21 Industrial Heavy Load Precision Motion Solution

What is Worm Gear Drive WE21

Worm Gear Drive WE21 is an advanced integrated rotational drive system engineered for extreme industrial environments. Its core architecture features a hardened precision-ground steel worm shaft engaging a high-strength bronze alloy worm wheel, encased within a rigid, sealed housing. Designed for efficient operation in protected conditions, the WE21 excels at simultaneously handling substantial axial loads (Static: 1598 kN), radial forces (Static: 640 kN), and tilting moments (203 kN·m). Its defining self-locking mechanism prevents back-driving during power loss, ensuring critical safety in vertical load-holding scenarios. Optimized ZA/ZK tooth profiles maximize contact efficiency, enabling exceptional torque transmission (28.7 kN·m) and speed reduction (90:1 ratio) while maintaining ≤0.1° tracking precision.

Critical Considerations for High-Speed Rotary Drive Selection

Selecting drives for high-RPM applications requires rigorous evaluation beyond basic specifications:

Torque-Speed Compatibility

Verify torque delivery at operational RPMs. Centrifugal forces at high speeds reduce effective torque capacity. Demand manufacturer-certified torque-speed curves covering your entire operating range.

Dynamic Stability & Precision

High RPM amplifies vibrations. Ensure the drive maintains ≤0.1° tracking precision under load at target speeds. Validate dynamic stiffness specifications to resist inertial deflection.

Thermal Management

Friction losses escalate exponentially with speed. Prioritize drives with optimized efficiency profiles (≥85% at rated load), thermal dissipation design (finned housings), and compatibility with forced-oil cooling systems.

High-Speed Lubrication Systems

Standard grease fails above 500 RPM. Require oil-lubricated designs with splash circulation, mist systems, or forced filtration to prevent lubricant starvation and centrifugal throw-off.

Bearing Performance Metrics

Confirm bearings are rated for combined dynamic loads (Axial: 385 kN, Radial: 335 kN for WE21) at maximum operational RPM. Calculate adjusted L10 life using dynamic equivalent loads.

Resonance Avoidance

Demand documented critical speed thresholds. Operating above 80% of the first critical frequency risks catastrophic vibration failure.

Dynamic Sealing Integrity

IP65 sealing must withstand centrifugal forces. Labyrinth seals or spring-energized fluoropolymer seals are essential for contamination exclusion.

Mass Optimization

High rotational inertia demands lightweight yet rigid components. Evaluate the drive’s reflected inertia relative to motor capabilities for rapid acceleration/deceleration.

Worm Gear Drive WE21 Technical Characteristics

Extreme Output Torque: 28.7 kN·m torque capacity drives heavy industrial presses, slewing cranes, and mining equipment.

Tilting Moment Resistance: 203 kN·m capacity maintains stability under severe off-center loading.

Fail-Safe Holding Torque: 105.8 kN·m holding torque with zero back-drive risk ensures vertical load security.

Premium Load Ratings: Engineered for 24/7 operation with Static Axial (1598 kN), Dynamic Axial (385 kN), Static Radial (640 kN), and Dynamic Radial (335 kN) ratings.

Optimized Reduction Ratio: 90:1 gear ratio balances torque multiplication and operational speed requirements.

Micro-Precision Tracking: ≤0.1° repeatability enables radar positioning, telescope alignment, and robotic welding applications.

Zero-Backlash Self-Locking: Geometric self-locking eliminates need for auxiliary brakes while preventing positional drift.

Extreme Environment Protection: IP65-rated sealing withstands abrasive dust and high-pressure washdowns in foundries or offshore platforms.

Multi-Prime Mover Compatibility: Direct integration with hydraulic motors (up to 500 bar) or high-torque servo motors (IE4/IE5 efficiency class).

Advanced Metallurgy: Case-hardened 18CrNiMo7-6 worm shaft with grinding finish Ra≤0.4μm + phosphating; CuSn12Ni2-C worm wheel.

Industrial Applications of WE21

Heavy Lift Systems: Portal crane slewing rings, ship-to-shore gantry crane drives

Precision Defense Systems: Missile launcher azimuth drives, naval gun turret rotation

Mega Solar Tracking: Utility-scale solar farm azimuth-elevation drives

Mining Infrastructure: Bucket wheel excavator slewing drives, stacker-reclaimer rotation

Hydraulic Press Systems: 10,000+ ton metal forming press indexers

Aerospace Test Rigs: Satellite antenna position simulators, structural load testers

Marine Handling: Offshore crane luffing drives, dynamic positioning thrusters

Nuclear Infrastructure: Shield door actuators, fuel handling manipulator

High-Inertia Rotators: Industrial mixer drives >15-ton vessels, wind tunnel fan drives

Cost Drivers for Worm Gear Drive WE21

Material Premium: Aircraft-grade steel alloys (AMS 6265/AMS 6470) for worms and nickel-tin bronze (C95800) for gears increase raw material costs by 35-50% versus standard alloys.

Precision Manufacturing: CNC profile grinding (DIN 3974 Class 6 accuracy), carburizing to 60-64 HRC depth ≥2mm, and coordinate measuring machine (CMM) validation add 25+ hours of skilled labor per unit.

High-Capacity Bearing Systems: Custom 4-row tapered roller bearings rated for combined axial/radial/moment loads (L10 life >30,000 hrs at max dynamic load) constitute 18-22% of total cost.

Advanced Sealing Solutions: Triple-lip hydrodynamic seals with PTFE spring energizers and multi-stage labyrinth systems increase sealing costs by 300% versus standard units.

Performance Validation: 72-hour continuous load testing (per ISO 14521) with thermal imaging and vibration spectrum analysis adds significant QA overhead.

Housing Integrity: Nodular graphite cast iron (EN-GJS-400-18-LT) housings requiring stress-relieving and 5-axis machining account for 30% of mass and 20% of cost.

Customization Premium: Non-standard shaft configurations (flanged hollow shafts, keyed outputs) or special coatings (Magnaplate HCR®) incur 15-40% surcharges.

Engineering Partner for WE21 Solutions

LYRADRIVE delivers certified Worm Gear Drive WE21 systems through ISO 9001:2015 manufacturing facilities equipped with climate-controlled metrology labs. Their vertical integration covers everything from alloy formulation to final performance validation, providing full traceability documentation. Global technical support teams offer application engineering, including FEA analysis of mounting structures and thermal modeling for extreme environments. With distribution centers in Germany, USA, and Singapore, LYRADRIVE guarantees 30-day lead times for standard WE21 units with lifetime lubrication and 24-month performance warranties.