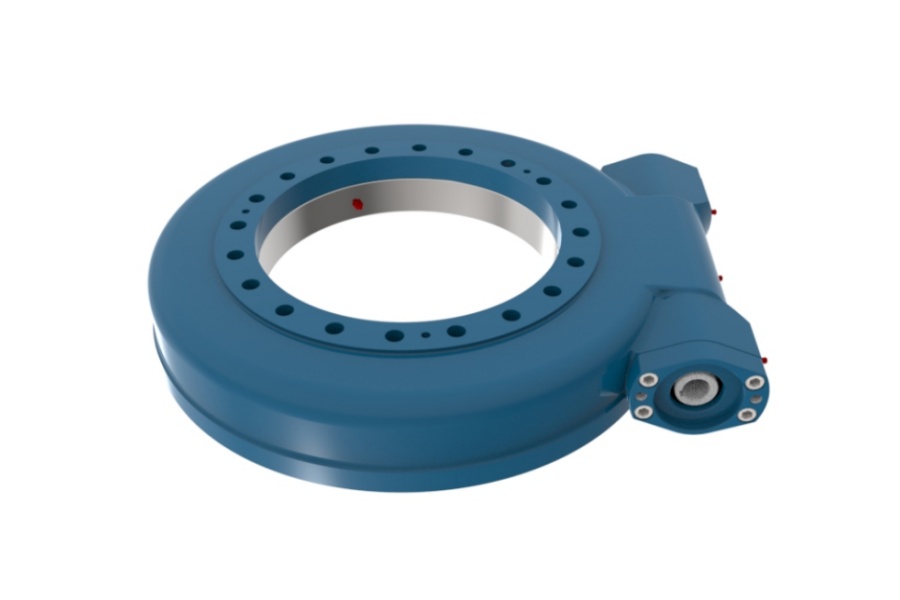

Worm Gear Drive WE17 for Demanding Industrial Applications

What is Worm Gear Drive WE17

Worm Gear Drive WE17 is a high-performance industrial drive unit meticulously engineered for durability and precision. Its core components comprise a hardened, precision-ground worm shaft meshing with a high-strength bronze alloy worm wheel, all housed within a rigid, sealed casing. This configuration operates within a protected environment, ensuring longevity and consistent performance. The WE17 excels at simultaneously handling significant axial loads, radial forces, and tilting moments. Its inherent self-locking capability enhances operational safety by preventing back-driving when power is removed, making it exceptionally reliable for critical positioning and holding tasks. Designed to deliver substantial torque multiplication and speed reduction, the WE17 often utilizes optimized ZA or ZK worm profiles to maximize contact efficiency and power transmission capability within its compact form factor.

How Gear Modification Design Impacts Transmission Performance

Gear modification, particularly profile shifting applied to the worm wheel in worm gear sets like the WE17, is a critical design strategy significantly influencing transmission characteristics. While less common than in spur or helical gears, targeted modification in worm gears addresses specific performance goals:

Enhanced Load Capacity: Strategic shifting can optimize the contact pattern between the worm and wheel teeth. This distributes stresses more evenly across the tooth flanks, reducing peak pressures at the ends of the worm thread or the tips of the wheel teeth. This leads to increased resistance to pitting, scoring, and wear, directly boosting the drive's load-carrying ability and operational lifespan under demanding conditions.

Improved Efficiency: Modifying the tooth profiles can minimize sliding friction at critical engagement points. By adjusting the relative curvature of the meshing surfaces, engineers can reduce the contact stress and friction coefficient locally, leading to a measurable improvement in the overall transmission efficiency. This is crucial for high-power applications where energy loss translates to heat and reduced performance.

Controlled Backlash: Backlash, the slight clearance between meshing teeth, is essential for smooth operation and lubrication but must be minimized for precision applications. Gear modification allows for precise control over this backlash during manufacturing and assembly. By carefully adjusting the center distance and tooth profiles, manufacturers can achieve the optimal minimal backlash required for the WE17's specified ≤0.1° tracking precision without risking binding or excessive wear.

Optimized Contact Pattern: A well-centered and appropriately sized contact area is vital for smooth, quiet operation and uniform load distribution. Profile shifting allows designers to position the contact zone optimally on the worm wheel tooth surface, avoiding edge loading near the root or tip which can cause premature failure. This ensures stable operation and minimizes noise and vibration.

Increased Durability: The cumulative effect of optimized load distribution, reduced peak stresses, minimized detrimental friction, and a controlled contact pattern directly translates to increased durability and resistance to wear. Modified gears often exhibit significantly longer service lives, especially under variable or heavy loads, reducing maintenance frequency and downtime. For the WE17, this modification contributes directly to its impressive static and dynamic load ratings.

Worm Gear Drive WE17 Characteristics

The WE17 stands out due to its exceptional combination of power, precision, and resilience:

High Output Torque: Delivering a formidable 12.96 kN·m of output torque, the WE17 is engineered to handle the most strenuous industrial tasks involving heavy lifting, pressing, or positioning.

Superior Tilting Moment Capacity: With a tilting moment resistance of 142.4 kN·m, the drive maintains exceptional stability even when subjected to significant off-center or overturning loads, crucial for applications like slewing rings or large manipulators.

Robust Holding Torque: Providing 72.3 kN·m of holding torque, the WE17 reliably secures loads in position, leveraging its inherent self-locking nature. This is essential for safety in hoisting, clamping, and indexing applications where unintended movement is unacceptable.

Significant Load Ratings: Engineered for demanding environments, the WE17 boasts high static (Axial: 1166 kN, Radial: 435 kN) and dynamic (Axial: 280 kN, Radial: 231 kN) load capacities, ensuring reliable operation under both steady-state and operational stresses.

Optimal Gear Ratio: The 104:1 reduction ratio provides substantial speed reduction and corresponding torque amplification, making it ideal for applications requiring powerful, controlled, low-speed movement.

Exceptional Tracking Precision: Achieving tracking precision ≤0.1°, the WE17 enables highly accurate positioning and repeatable motion control, suitable for automated machinery, radar systems, antenna positioning, and robotic applications.

Inherent Self-Locking: The fundamental design of the worm and wheel interface creates a self-locking effect. This critical safety feature prevents the output shaft from back-driving the input worm when power is removed, ensuring load security without additional braking mechanisms in many scenarios.

Robust Protection (IP65): Sealed to IP65 standards, the WE17 is protected against dust ingress and low-pressure water jets from any direction. This allows reliable operation in harsh industrial environments, both indoors and outdoors.

Versatile Drive Compatibility: Designed for flexibility, the WE17 readily interfaces with various prime movers, including hydraulic motors for high power density or electric motors (servo, AC, DC) for precise control, adapting to diverse power systems.

Durable Construction: Utilizing high-grade materials like hardened steel for the worm and wear-resistant bronze alloys for the wheel, coupled with precision manufacturing, ensures longevity and consistent performance even under continuous operation.

Worm Gear Drive WE17 Applications

The WE17's blend of high torque, precision, self-locking, and robustness makes it indispensable across numerous demanding sectors:

Heavy Machinery: Excels in slewing drives for cranes (mobile, tower, overhead), excavators, and heavy-duty material handling equipment requiring precise rotation under massive loads.

Industrial Automation: Powers rotary indexing tables, precision positioning stages, heavy-duty robotic joints, and automation cells where accurate angular positioning and holding are paramount.

Material Handling: Integral to conveyor drives, palletizers, stacker/reclaimers, and large gate/valve actuators where controlled movement and reliable holding are critical.

Defense & Aerospace: Used in radar pedestals, satellite communication (SATCOM) antenna positioning systems, missile launcher positioning, and optical tracking platforms demanding high precision and stability.

Renewable Energy: Drives solar tracker systems for precise panel orientation and yaw/pitch control mechanisms in wind turbines.

Construction Equipment: Found in concrete boom pumps, drilling rigs, and heavy lift equipment requiring robust rotational motion.

Packaging Machinery: Powers rotary filling stations, capping machines, and turntables needing high torque at low speeds.

Stage & Entertainment Technology: Drives heavy-duty stage lifts, rotating platforms, and large lighting rig movements requiring smooth, controlled, and secure operation.

Test & Simulation Equipment: Provides precise angular positioning and high torque for dynamometers, fatigue testers, and motion simulators.

Factors Influencing Worm Gear Drive WE17 Price

The cost of a Worm Gear Drive WE17 is determined by several key factors reflecting its complexity, quality, and performance:

Material Selection & Quality: The use of high-performance materials significantly impacts cost. Premium hardened steel alloys for the worm shaft and specialized bronze alloys (often containing nickel or tin) for the worm wheel, chosen for their strength, wear resistance, and compatibility, are major cost drivers. The quality and traceability of these raw materials also factor in.

Precision Manufacturing & Tolerances: Achieving the WE17's ≤0.1° precision and high load ratings requires advanced, high-precision machining, grinding (especially for the worm profile), and heat treatment processes. Tighter tolerances and superior surface finishes demand more sophisticated equipment, skilled labor, and rigorous quality control, increasing manufacturing costs substantially.

Gear Modification & Design Complexity: Implementing specific gear profile modifications (ZA, ZK profiles, profile shifting) to optimize load capacity, efficiency, and backlash control adds complexity to the design and manufacturing process, requiring specialized tooling and expertise, thus increasing cost.

Load Ratings & Performance Specifications: Higher static and dynamic load ratings (axial, radial, tilting moment) necessitate more robust internal designs, larger bearings, stronger housings, and potentially larger overall size within the WE17 class, directly correlating with increased material usage and manufacturing effort. The high holding torque and self-locking reliability are outcomes of this robust design.

Sealing & Protection Level: Achieving and maintaining the IP65 rating requires high-quality seals (lip seals, labyrinth designs), specialized greases, and careful housing design to prevent ingress. These components and assembly processes add to the unit cost.

Testing & Quality Assurance: Comprehensive testing protocols to verify load ratings, efficiency, precision, backlash, durability, and sealing integrity under simulated operating conditions represent a significant investment in time and equipment, contributing to the final price. Certifications (ISO, etc.) add further assurance and cost.

Order Volume & Customization: Economies of scale apply; larger production runs typically reduce the unit cost. Conversely, any customization (special shaft configurations, flanges, coatings, specific lubrication, modified ratios within the design envelope) will increase the price compared to a standard catalog item.

Bearing Quality & Configuration: The bearings supporting the worm shaft and output shaft must withstand high axial, radial, and moment loads simultaneously. Using high-capacity, precision bearings (often tapered roller or specialized angular contact types) is essential for performance and longevity but adds cost.

Housing Complexity & Material: The housing must be rigid enough to maintain alignment under load and accommodate sealing. Cast iron or ductile iron housings offer the necessary strength and damping properties but require precise casting and machining.

Supplier of Worm Gear Drive WE17

For industrial users seeking the proven performance and reliability of the Worm Gear Drive WE17, LYRADRIVE stands as a premier global supplier and manufacturer. LYRADRIVE specializes in the design, engineering, and production of high-precision worm gear drives, slewing ring bearings, and integrated drive systems tailored for demanding applications across diverse industries. Their commitment to rigorous quality control, advanced manufacturing techniques, and deep technical expertise ensures that every WE17 unit meets exacting standards for performance, durability, and precision. LYRADRIVE provides comprehensive technical support, from selection assistance through installation guidance, helping customers integrate the WE17 effectively into their machinery for optimal results. Their global presence facilitates reliable supply chains and responsive service, making them a trusted partner for critical drive solutions.