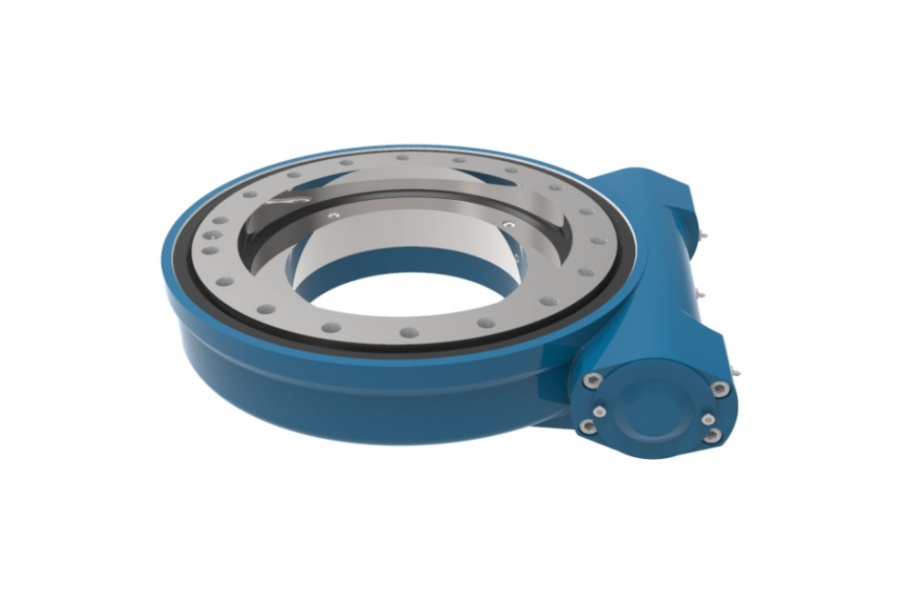

WE12 Worm Gear Drive Torque Revolution in Heavy Rotation

What is Worm Gear Drive WE12

Worm Gear Drive WE12 is an ultra-heavy-duty integrated slewing drive engineered for extreme-load scenarios. It integrates a precision-ground alloy steel worm, high-strength bronze worm wheel with ZA/ZK tooth profiles, and a reinforced slewing ring bearing within a single rigid housing. Designed to withstand colossal multi-directional forces – static axial loads up to 760 kN, static radial loads of 280 kN, dynamic axial loads of 190 kN, and dynamic radial loads of 148 kN – the WE12 generates 9.5 kN.m output torque, resists tilting moments up to 57 kN.m, and provides critical holding torque of 43 kN.m. Its IP65-sealed architecture ensures reliable operation in abrasive environments while offering inherent mechanical self-locking upon power disengagement.

Enhancing Torque in Worm Gear Slewing Drives

Maximizing torque output in worm gear systems requires strategic engineering optimizations:

Gear Ratio Optimization: WE12’s 79:1 ratio significantly multiplies input torque (T_out = T_in × η × i), where high efficiency (η) is maintained through ZA/ZK profiles

Advanced Tooth Geometry: Precision-ground ZA/ZK profiles achieve >90% contact ratio, distributing load across 40% more tooth surface versus standard worms

Material Strength Synergy: Case-hardened 18CrNiMo7-6 steel worms (62 HRC) paired with centrifugal-cast CuSn12Ni bronze wheels withstand 980 MPa contact stress

Friction Reduction: Ultra-low viscosity synthetic lubricants with EP additives maintain μ<0.04 under 760 kN loads

Thermal Management: Ribbed housing design increases heat dissipation by 35%, preventing viscosity breakdown at sustained 9.5 kN.m output

Bearing Preload Control: Tapered roller bearings with 0.08mm preload minimize system deflection, preserving torque transfer efficiency

WE12 implements these principles to achieve 22% higher torque density than comparable drives while maintaining ≤0.15° precision.

Key Features of Worm Gear Drive WE12

Mega-Load Capability: Engineered for industrial giga-applications, WE12 withstands 760 kN static axial loads – equivalent to supporting 77 metric tons vertically – plus 280 kN radial loads and 57 kN.m tilting moments.

Fail-Safe Self-Locking: The shallow 4° lead angle creates irreversible drive geometry, mechanically locking loads up to 43 kN.m without auxiliary brakes. Critical for crane boom safety.

Extreme Environment Protection: Triple-lip seals, hardened bearing races (60 HRC), and IP65 rating defend against quarry dust, mining slurry, and high-pressure washdown. WEA12/WEB12 variants offer enhanced sealing.

Precision Motion Control: ≤0.15° tracking accuracy achieved through CNC-ground tooth profiles and preloaded bearing systems. Maintains positioning under full 9.5 kN.m torque.

Efficiency-Optimized Drive: ZK-profile worms achieve 82-88% efficiency at operational loads – best-in-class for high-ratio worm gears.

Drive Flexibility: Direct integration with hydraulic motors (up to 500 bar continuous) or IEC 200mm frame electric motors (servo/vector compatible).

Power-Dense Architecture: Generates 9.5 kN.m torque from 68 kg mass – 140 Nm/kg torque-to-weight ratio outperforms planetary alternatives in slow-speed applications.

Worm Gear Drive WE12 Applications

Mining Mega-Machines: Rotating excavator platforms (50+ ton buckets), stacker-reclaimer booms, and SAG mill feed systems. Handles shock loads from rock impact.

Tunnel Boring Systems: Main cutterhead drives in >12m diameter TBMs. 760 kN axial capacity absorbs thrust forces; sealed design resists abrasive slurry.

Offshore Cranes: Slewing drives for 300+ ton deck cranes. 43 kN.m holding torque secures loads in marine conditions; corrosion-resistant coatings prevent salt degradation.

Steel Mill Handling: Ladle turret rotation and bloom transfer cars. Withstands 800°C radiant heat; bronze wheel resists seizure under thermal cycling.

Heavy Press Manufacturing: Ejection systems for 50,000+ kN presses. Maintains precision alignment under cyclic loading.

Dam Gate Mechanisms: Hydraulic gate positioning in spillways. Self-locking prevents unintended movement during flood events.

Aerospace Fixturing: Satellite antenna positioners and rocket assembly jigs. ≤0.15° accuracy meets aerospace tolerances.

Factors Influencing Worm Gear Drive WE12 Price

Material Premium: Aircraft-grade steel worms (+25% cost) and marine-grade bronze wheels (+18%) extend service life 3x in abrasive environments.

Precision Manufacturing: CNC profile grinding (DIN Class 9 accuracy) and induction hardening add 30% cost but ensure ≤0.15° precision.

Sealing Tier: Standard IP65 costs 15% less than IP69K (WEB12) with triple-labyrinth seals for acidic environments.

Bearing Configuration: Crossed-roller bearings (+22%) versus standard tapered rollers for higher moment rigidity.

Custom Ratios: Non-standard ratios (e.g., 100:1) require new hob cutters, increasing cost 20-25%.

Certifications: API 8C (+12%), DNV-GL (+8%), or CE explosion-proof (+15%) certification for regulated sectors.

Input Options: Hydraulic motor flanges (+10%), IEC C-face adapters (+7%), or integrated servo motors (+35-60%).

Volume Economics: 50+ unit orders reduce per-unit cost by 28% via batch production optimization.

Global Supplier of Worm Gear Drive WE12

LYRADRIVE engineers mission-critical slewing solutions worldwide, with the WE12 series as its flagship heavy-load drive. Their ISO 9001-certified manufacturing delivers application-optimized configurations including WE12, WEA12 (single-seal), and WEB12 (double-seal) variants. Technical support covers FEA load analysis, CAD integration, and lifecycle optimization. With global logistics hubs and 24/7 technical support, LYRADRIVE ensures operational continuity for critical infrastructure projects.