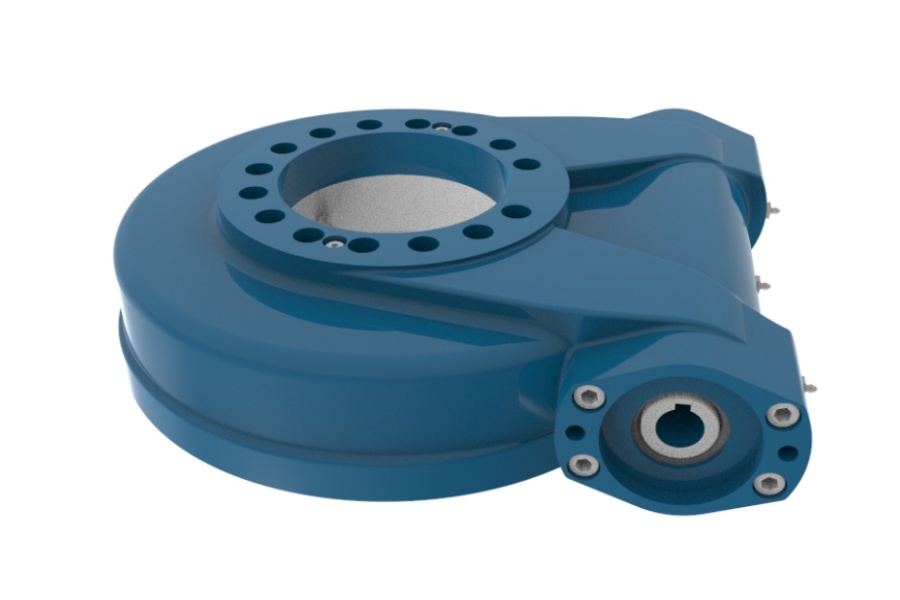

WE9 Worm Gear Drive Mastering Heavy Loads with Sliding Efficiency

What is Worm Gear Drive WE9

Worm Gear Drive WE9 is an advanced integrated slewing drive system engineered for extreme-duty performance. It combines a precision-ground hardened steel worm, a high-strength bronze worm wheel with ZA/ZK tooth profiles, and a heavy-duty slewing ring bearing within a single rigid housing. Designed to handle immense multi-directional loads – static axial forces up to 578 kN, static radial loads of 215 kN, dynamic axial loads of 136 kN, and dynamic radial loads of 115 kN – the WE9 delivers an output torque of 8 kN.m, a tilting moment capacity of 35.6 kN.m, and a critical holding torque of 38.7 kN.m. Its compact, sealed architecture (IP65-rated) ensures reliable operation in harsh environments while providing inherent self-locking security upon power disengagement.

Sliding Speed Impact on Worm Drive Efficiency

In worm gear transmissions, sliding velocity between the worm and wheel teeth fundamentally governs efficiency. Unlike rolling contact in gears, worm drives experience significant interfacial sliding. Higher sliding speeds (calculated as *v = π × d_worm × n_worm / (60,000 × cosγ)*, where d_worm is pitch diameter, n_worm is RPM, and γ is lead angle) generate more friction-induced heat, reducing efficiency by 15-40% compared to gear types. The WE9 counters this through precision engineering:

Optimal Lead Angle Design: WE9's calculated lead angle minimizes sliding velocity at operational RPMs.

Advanced Tooth Profiling: ZA/ZK profiles maximize contact area, distributing sliding forces and reducing localized heat buildup.

Material Synergy: Hardened steel worm paired with phosphor bronze wheel provides low-friction coefficients (<0.05 under optimal lubrication).

Thermal Management: High-viscosity synthetic lubricants and efficient heat dissipation paths maintain viscosity integrity, preventing efficiency drop at sustained loads.

While sliding limits peak efficiency, WE9’s design achieves 70-85% efficiency in its operating range – exceptional for worm drives – by strategically balancing sliding velocity, contact pressure, and thermal control.

Key Features of Worm Gear Drive WE9

Extreme Load Capacity: Engineered for industrial megaton applications, WE9 withstands 578 kN static axial loads, 215 kN static radial loads, and 38.7 kN.m holding torque – ideal for vertical lifting and dynamic stabilization.

Precision Self-Locking: The worm’s shallow lead angle ensures mechanical self-locking at rest, preventing back-driving even under 38.7 kN.m load. Critical for safety in cranes or tilt systems.

IP65 Sealed Robustness: Triple-lip seals and hardened bearing races block dust/water ingress in quarry, marine, or washdown environments. WEA9/WEB9 variants offer enhanced sealing for slurry/powder extremes.

High-Precision Motion: ≤0.15° tracking accuracy enables exact positioning in automation, achieved via CNC-ground teeth and preloaded tapered roller bearings.

Efficiency-Optimized Gearing: ZA/ZK profile worms maximize power transfer while minimizing sliding losses. Precision grinding ensures >85% contact ratio.

Flexible Drive Integration: Direct mounting for hydraulic motors (high torque-variability) or IEC/NEMA electric motors (servo/vector control). 62:1 standard ratio balances torque and speed.

Compact Power Density: Delivers 8 kN.m torque from a 54 kg package – superior power-to-weight for space-constrained installations.

Worm Gear Drive WE9 Applications

Mining & Bulk Handling: Rotating excavator buckets, conveyor trippers, and stacker-reclaimers. Handles shock loads from rock impact while self-locking prevents uncontrolled slew.

Heavy-Duty Cranes: Swing drives for mobile cranes and jib cranes. 38.7 kN.m holding torque secures loads at height; IP65 rating endures outdoor exposure.

Tunnel Boring & Drilling: Drives cutterhead positioning systems. Axial load capacity (578 kN) handles thrust forces; sealed design resists abrasive slurry.

Steel Mill Equipment: Tilting ladles and roller table drives. Withstands radiant heat and ingot loads; bronze wheel resists seizure under thermal cycling.

Offshore & Shipboard: Deck crane slewing and hatch covers. Corrosion-resistant coatings and sealed bearings prevent saltwater degradation.

Precision Solar Trackers: Azimuth drives for utility-scale PV systems. ≤0.15° accuracy optimizes sun alignment; self-locking reduces actuator power draw.

Industrial Presses & Foundries: Ejection systems and die-tilting. Reliable under 24/7 cycling; thermal stability maintains precision.

Factors Influencing Worm Gear Drive WE9 Price

Material Specifications: Aircraft-grade alloy steel worms (18CrNiMo7-6) and centrifugal-cast bronze wheels (CuSn12Ni) increase cost 20-30% versus standard alloys but extend service life 3x.

Precision Manufacturing: CNC profile grinding (DIN Class 8+ accuracy), induction hardening (60-62 HRC), and bearing race superfinishing add 15-25% cost but ensure ≤0.15° precision.

Sealing Tier: Standard IP65 costs 10% less than IP69K (WEB9) or triple-labyrinth seals for acidic/abrasive environments.

Ratio Customization: Non-standard ratios (e.g., 80:1 for higher torque) require new tooling, increasing unit cost 12-18%.

Bearing Configuration: Tapered roller bearings (standard) cost less than crossed-roller variants (higher moment rigidity).

Input Drive Options: Hydraulic motor adapters (+8-12%), IEC flange kits (+5%), or integrated servo motors (+25-50%).

Order Volume: 100+ unit batches reduce per-unit cost by 22-30% via optimized material sourcing and production flow.

Certifications: ISO 6336 calculation documents, CE machinery certification, or DNV-GL marine approval add 5-10% but enable regulated markets.

Trusted Supplier of Worm Gear Drive WE9

LYRADRIVE delivers engineered heavy-duty slewing solutions globally, with the WE9 series as a flagship product. Combining ISO 9001-certified manufacturing with in-house R&D, LYRADRIVE provides application-specific drives – including WE9, WEA9 (single-seal enhanced), and WEB9 (double-seal extreme) variants. Their technical team supports load analysis, CAD integration, and lifecycle optimization, ensuring drives meet exact operational demands. With streamlined global logistics and comprehensive after-sales support, LYRADRIVE guarantees reliability where performance cannot falter.