Excavator Slewing Bearing Guide

What is Excavator Slewing Bearing

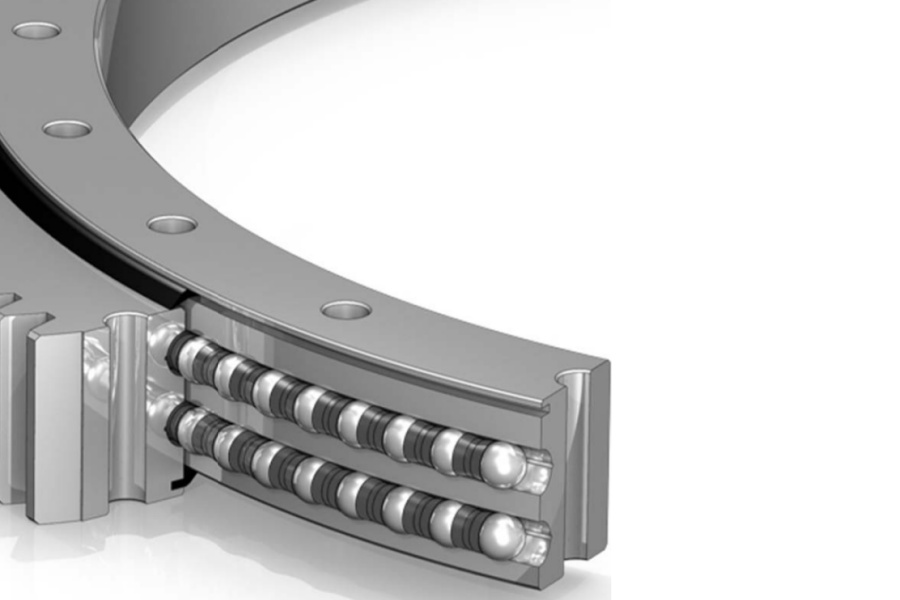

The excavator slewing bearing is a critical large-diameter rolling bearing connecting the upper structure (cab, boom, arm, bucket, hydraulics) to the lower undercarriage (tracks/wheels). It enables smooth rotation while supporting the upper weight and enduring extreme combined loads: axial forces, radial forces, and overturning moments. Common types include Single-Row Four-Point Contact Ball Bearings, Double-Row Ball Bearings (Eight-Point Contact), and for ultra-large mining excavators, Internal Gear Three-Row Cylindrical Roller Bearings. Key components are an inner ring (bolted to the undercarriage with internal gear teeth), an outer ring (bolted to the upper structure), hardened steel balls/rollers, and precision cages. Rotation is driven by a slewing motor pinion meshing with the inner ring's teeth. Raceways use a Gothic arch profile for multi-point contact and are induction hardened (HRC 55-60, 2.5-5mm depth) for wear resistance; gear teeth are quenched to HRC 45-50 for balanced toughness and wear resistance. Outer ring mounting holes often have non-uniform patterns, requiring strict part number matching during replacement.

How to Quickly and Accurately Measure Slewing Bearing Raceway Diameter

Accurate raceway diameter measurement is vital for assessing wear, determining replacement needs, or verifying manufacturing tolerances. Achieving both speed and precision requires the right tools and methodology:

Preparation is Paramount:

Thorough Cleaning: Remove all grease, debris, and rust from the raceway using industrial degreasers and non-abrasive tools. Any residue compromises measurement accuracy.

Accessibility: Ensure clear access to the entire raceway circumference. Remove seals if necessary.

Stable Environment: Perform measurements in a stable temperature environment to minimize thermal expansion effects.

Selecting the Optimal Tool:

Large Diameter Vernier Caliper (Telescoping Gauge + Micrometer Combo):

Method: Insert the telescoping arms into the raceway, gently expand them until they firmly contact the raceway walls at the desired measurement height (ensure perpendicularity), lock the arms, carefully withdraw, and measure the distance between the arm tips with a high-precision micrometer.

Pros: Relatively affordable, portable.

Cons: Highly operator-dependent skill. Prone to errors from tilt, pressure variation, or withdrawal disturbance. Slow for multiple points. Accuracy typically ±0.05-0.1mm.

Precision Bridge Gauge (Raceway Gauge):

Method: A purpose-built tool with hardened, fixed anvils matching standard raceway curvatures or adjustable anvils. Placed directly into the raceway groove, it provides a direct readout via a dial indicator or digital display.

Pros: Designed for the task, faster and less operator-dependent than telescoping gauges. Better repeatability (±0.02-0.05mm).

Cons: Requires correct size/anvil profile for the specific bearing. May not fit all access constraints. Cost higher than basic calipers.

3D Coordinate Measuring Machine (CMM) or Portable Measuring Arm:

Method: Uses a touch probe or laser scanner to capture numerous data points along the raceway profile. Sophisticated software calculates the best-fit diameter and assesses form errors (ovalty, taper).

Pros: Highest accuracy (±0.005mm or better). Provides comprehensive data (diameter, roundness, groove profile). Ideal for OEMs or advanced rebuild shops.

Cons: Very expensive. Requires specialized training and controlled environment (for fixed CMM). Portable arms offer flexibility but still significant investment.

Laser Tracker or Laser Radar:

Method: Uses laser interferometry to measure the position of a target moved around the raceway. Creates a highly accurate point cloud for diameter calculation.

Pros: Exceptional accuracy over very large diameters. Non-contact.

Cons: Extremely high cost. Complex setup and operation. Primarily used by OEMs or for critical large-bearing certification.

Measurement Protocol for Accuracy:

Define Measurement Plane: Consistently measure at the centerline of the ball/roller path depth-wise.

Multiple Points: Take measurements at a minimum of 4-6 equally spaced locations around the circumference (e.g., every 60-90 degrees).

Consistent Pressure: Apply gentle, consistent contact pressure with the measuring tool. Avoid forcing or wedging.

Perpendicularity: Ensure the measuring tool or anvils are perpendicular to the tangent point on the raceway wall.

Record & Compare: Log all measurements. Compare to the bearing’s original specifications or OEM tolerance charts to determine wear or conformity. Significant variations indicate ovalty or wear.

Calibration: All measuring tools must be regularly calibrated against traceable standards.

Prioritize Precision for Critical Decisions: While "quick" methods exist (like telescoping gauges), investing time in proper technique with the best available tool (like a bridge gauge or CMM) ensures the accuracy needed for reliable assessment of bearing condition or manufacturing quality. Rushed, inaccurate measurements lead to costly mistakes.

Characteristics of Excavator Slewing Bearings

Excavator Slewing Bearings are defined by characteristics engineered for relentless duty cycles in abrasive, high-shock environments:

Internal Gearing Standard: Teeth on the inner ring mesh directly with the slewing motor pinion, optimizing space and torque transmission for the typical excavator layout.

High Load Density Design: Maximizes axial, radial, and moment load capacity within minimal axial section height, crucial for excavator compactness. Single-row ball designs excel here.

Exceptional Moment Resistance: Engineered to withstand massive overturning moments generated by extended booms, heavy buckets, and intense digging forces at maximum reach.

Robust Construction: Forged or rolled high-strength alloy steel rings (e.g., 50Mn, 42CrMo) form the core.

Advanced Surface Hardening: Raceways undergo medium-frequency induction quenching (HRC 55-60, depth 2.5-5mm) for supreme resistance to brinelling, wear, and rolling contact fatigue.

Optimized Gear Hardening: Internal gear teeth hardened to HRC 45-50 via M/F quenching – balancing wear resistance with essential toughness to absorb impact loads without brittle fracture.

Four/Eight-Point Contact: Gothic arch raceways enable balls to handle combined loads efficiently. Double-row designs offer higher capacity.

Precision Rolling Elements: High-grade, tightly tolerance steel balls or cylindrical rollers ensure smooth motion and even load distribution.

Durable Cages: Precision cages (polyamide, brass, or sintered bronze) maintain element spacing, minimize friction, and withstand high inertial forces during sudden starts/stops.

Heavy-Duty Sealing: Multi-lip seals (often NBR or FKM) with labyrinth features aggressively exclude abrasive contaminants (soil, sand, water) while retaining grease. Integral dust lips are common.

Asymmetric Mounting: Outer ring mounting holes are often non-uniformly spaced, requiring precise alignment during installation based on part number.

Integrated Lubrication: Grease fittings and often internal channels allow for re-lubrication to purge contaminants and maintain protective grease films.

Tight Internal Clearance: Controlled clearance ensures rigidity and stability under high moments while maintaining smooth rotation.

High Impact Resistance: Material selection, hardening, and design accommodate severe shock loads inherent in digging and rock breaking.

Applications of Excavator Slewing Bearings

Excavator Slewing Bearings are fundamental to all hydraulic excavators across diverse industries:

Mini/Midi Excavators: Compact machines (1-10 tons) for landscaping, utility work, and light construction. Use smaller single-row ball bearings.

Standard Crawler Excavators: The most common type (10-50 tons) for general construction, demolition, road building, and trenching. Primarily use single-row four-point contact or double-row ball bearings.

Large Crawler Excavators (50-100+ tons): Heavy construction, quarrying, and mining loading applications. Utilize larger single-row or double-row ball bearings, demanding higher load ratings.

Mining Shovels & Face Shovels: Massive excavators (><|place▁holder▁no▁797|> tons) for bulk material removal in mining. Often employ large-diameter internal gear three-row cylindrical roller bearings for extreme moment capacity.

Wheeled Excavators: Offer mobility between sites on public roads. Utilize slewing bearings similar to equivalent-sized crawler models.

Long-Reach Excavators: Specialized machines for dredging, demolition, or deep digging. Require bearings optimized for exceptionally high overturning moments at full extension.

Demolition Excavators: Fitted with breakers or shears, subjecting bearings to intense, constant vibration and shock loads. Need enhanced robustness and sealing.

Material Handler Excavators: Equipped with grapples or sorting grabs for handling scrap, logs, or recycling materials. Experience high cyclic loading.

Compact Track Loaders (CTLs) with Excavator Attachments: Utilize scaled-down slewing bearings in the rotating excavator attachment.

Factors Influencing Excavator Slewing Bearing Price

The price of an Excavator Slewing Bearing reflects its complexity, material quality, and precision:

Size & Type: Diameter and axial height are primary drivers. Larger bearings cost exponentially more. Three-row rollers are significantly more expensive than single-row balls for comparable diameters.

Load Ratings (Axial, Radial, Moment): Higher specified capacities require larger cross-sections, more/larger rolling elements, enhanced materials, and tighter tolerances.

Material Grade & Quality: High-purity, high-strength alloy steel forgings (50Mn, 42CrMo) with superior fatigue properties cost more. Origin and certifications (mill certs) add cost.

Heat Treatment Complexity: Medium-frequency quenching of large raceways and gears is energy-intensive and requires precise control. Depth and hardness consistency verification add cost.

Precision Machining: Achieving tight geometric tolerances on large rings (raceway profile, gear tooth accuracy, mounting surface flatness, bolt hole position) demands advanced CNC machining and rigorous inspection (CMM), significantly increasing production time and cost.

Internal Gearing: Gear module size, tooth width, profile accuracy, and the controlled hardening process (HRC 45-50) are major cost factors. Larger gears cost more.

Rolling Element Quality: High-precision balls/rollers meeting strict size, sphericity, and hardness tolerances are costly. Quantity needed scales with size.

Cage Design & Material: Complex or high-performance cages (machined brass, engineered polymers) cost more than simple pressed steel.

Sealing System: Multi-lip seals with specialized elastomers (FKM for high temp), integral dust excluders, and robust designs add cost.

Asymmetric Hole Machining: Non-standard hole patterns require custom fixturing and programming.

Quantity & Standardization: Mass production of common sizes offers economies. Custom or low-volume bearings incur high per-unit engineering and setup costs.

Quality Assurance: Costs for material certification, process records, non-destructive testing (MPI, UT), dimensional reports, and certifications (ISO 9001, OEM approvals).

Brand Reputation & Support: Premium manufacturers with proven reliability, engineering support, and global service networks command higher prices.

Market Dynamics: Fluctuations in global steel prices, energy costs, and logistics impact final pricing.

Supplier Spotlight of Excavator Slewing Bearings

Sourcing reliable Excavator Slewing Bearings demands partnering with a manufacturer possessing proven expertise in heavy-duty applications. LYRADRIVE is recognized for engineering and manufacturing robust slewing bearings specifically designed to endure the punishing conditions faced by excavators. Their focus encompasses utilizing high-grade materials, implementing stringent heat treatment controls (raceway HRC 55-60, gear HRC 45-50), and maintaining precise manufacturing tolerances to ensure durability, high load capacity, and long service life under severe impact and contamination. LYRADRIVE emphasizes understanding the unique demands of digging applications, offering solutions backed by technical support for integration and maintenance, catering to equipment manufacturers and aftermarket needs across the excavator size spectrum.