Three Row Roller Slewing Bearing Guide

What is Three Row Roller Slewing Bearing

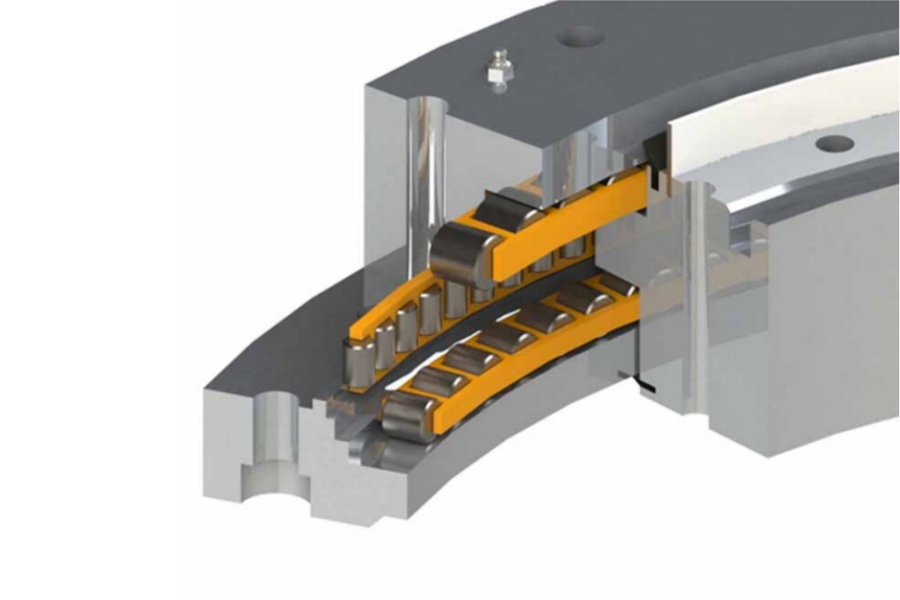

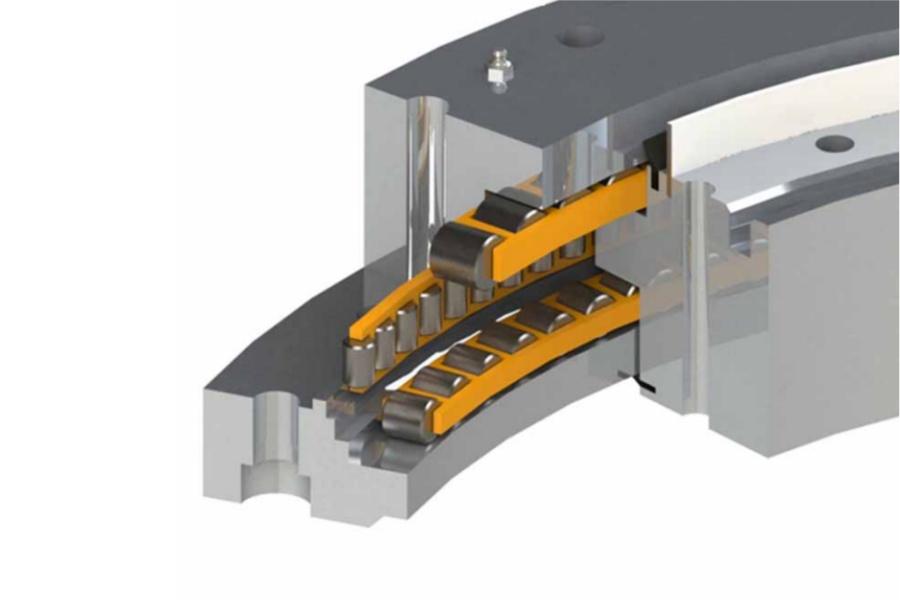

Three Row Roller Slewing Bearing is a highly specialized type of large-diameter rolling-element bearing engineered explicitly for applications requiring exceptional resistance to massive overturning moments combined with significant axial and radial forces. Its defining characteristic is the incorporation of three distinct, parallel rows of cylindrical rollers positioned between concentric inner and outer rings. Two of these roller rows are dedicated to handling axial loads – forces acting parallel to the bearing's axis of rotation. The third, radially oriented row is solely responsible for managing radial loads – forces acting perpendicular to the axis. This deliberate separation of load paths is key to its superior performance. The raceways, the precision-machined tracks upon which the rollers travel, typically employ a flat groove profile. To ensure exceptional durability and resistance to surface fatigue under immense pressure, these raceways undergo medium-frequency induction surface quenching. This specialized heat treatment process achieves a hardened surface layer with a hardness typically ranging from HRC 55 to 60, extending to a critical depth of 3mm to 6mm. Crucially, the cylindrical rollers interact with these hardened raceways through surface contact, distributing the massive loads over a significantly larger area compared to point contact bearings like ball types. This surface contact, combined with the dedicated load rows, grants the Three Row Roller Slewing Bearing its extraordinary load capacity and inherent stability, making it indispensable for massive structures experiencing severe operational stresses.

How is Roller Length Selected in Three Row Roller Slewing Bearings?

Selecting the optimal roller length within a Three Row Roller Slewing Bearing is a critical design decision driven by complex engineering calculations focused on load distribution, bearing life expectancy, and structural integrity. Longer rollers inherently offer a larger load-carrying surface area. This translates directly to a higher theoretical dynamic load rating for the bearing, meaning it can handle heavier loads over its design life. However, this benefit is counterbalanced by significant challenges. Longer rollers are inherently more susceptible to skewing and misalignment under load, especially if manufacturing tolerances or mounting deflections are not perfectly controlled. This misalignment can lead to detrimental edge loading, where excessive stress concentrates at the ends of the rollers, drastically accelerating wear and dramatically reducing the actual achievable bearing life (L10 life). Edge loading is the primary enemy of long roller performance. To mitigate this, extremely precise machining of the raceways and roller profiles is non-negotiable. Furthermore, the cage (spacer) design becomes paramount; it must impeccably guide the rollers, preventing skewing while minimizing friction. The cage material and strength must also withstand the significant forces involved. Consequently, roller length is not maximized indiscriminately. Engineers perform detailed finite element analysis (FEA) and life calculations (based on standards like ISO 281) to find the ideal compromise. They consider the specific magnitude and direction of the applied loads (axial, radial, moment), the required L10 life target, the achievable manufacturing precision for the raceways and rollers, the rigidity of the supporting structures (which influence deflections), and the capabilities of the cage design. The goal is to choose a roller length that provides sufficient load capacity to meet the application's demands while ensuring the rollers operate within their optimal stress range, minimizing edge effects and guaranteeing reliable, long-term performance under the predicted operating conditions. This intricate balance often results in rollers significantly shorter than the full width of the raceway contact zone.

Characteristics of Three Row Roller Slewing Bearings

Three Row Roller Slewing Bearings possess a distinct set of characteristics derived from their unique triple-row roller design, making them the preferred solution for applications where extreme loads and stability are paramount:

Exceptional Load Capacity: The dedicated axial and radial roller rows, combined with surface contact loading, allow these bearings to withstand immense axial loads, radial loads, and critically, very high tilting moments simultaneously. They offer the highest load ratings among common slewing bearing types for equivalent diameters.

Superior Stability and Rigidity: The separation of load paths and the inherent rigidity of the roller-to-raceway surface contact provide exceptional operational stability. This minimizes deflection and ensures precise positioning under heavy loads, crucial for large machinery.

Optimized Stiffness: The direct surface contact and the specific arrangement of the roller rows contribute to high stiffness in all loading directions (axial, radial, and moment), reducing unwanted movement and vibration.

High Moment Resistance: Their defining strength lies in their unparalleled ability to resist large overturning moments, a result of the wide separation between the two axial load-carrying rows. This makes them ideal for tall structures or long booms.

Robust Design for Harsh Environments: Engineered for severe service, these bearings feature heavy-section rings, high-strength alloy steel construction, and deep surface hardening (typically HRC 55-60, depth 3-6mm) on raceways. Sealing is often multi-layered and robust to protect against ingress of contaminants like dust, water, or abrasive particles.

Gearing Options: They are commonly manufactured in toothless, external gear, or internal gear configurations. Gear teeth can undergo various hardening treatments (tooth surface scanning quenching, medium-frequency quenching of tooth and root, or matrix hardening and tempering) based on torque transmission requirements and operating conditions. Pinion gear specifications are carefully matched to the bearing gear and application demands.

Precision Engineering: Achieving the necessary performance requires extremely tight tolerances in manufacturing the rings, rollers, and cages to ensure proper load distribution and prevent detrimental edge loading.

Lower Speed Rating: Due to higher friction inherent in roller designs compared to balls, they are generally suited for low to moderate rotational speeds.

Applications of Three Row Roller Slewing Bearings

The defining characteristics of Three Row Roller Slewing Bearings – their immense load capacity, high moment resistance, and exceptional stability – naturally lead them to be deployed in the most demanding heavy machinery sectors where failure is not an option:

Mining Giants: Buckwheel excavators and stacker-reclaimers rely on these bearings to support their massive rotating superstructures and booms under continuous, extreme digging and material handling loads.

Heavy Lifting: Large crawler cranes (often exceeding 500-ton capacity), heavy-duty mobile harbor cranes, sophisticated shipboard cranes (handling cargo or containers), and robust offshore pedestal cranes depend on them to handle the combined weight of the load, boom weight, and dynamic wind forces safely.

Port Operations: They are fundamental in the slewing mechanism of large ship-to-shore container cranes (STS) and rail-mounted gantry cranes (RMG), supporting the entire trolley and spreader system while handling massive container weights at significant outreach.

Steel Industry: Critical components in massive ladle turrets and molten steel turntables within continuous casting machines, where they support the weight of ladles filled with molten metal and endure intense thermal gradients.

Construction Mega-Machines: Found in the slewing rings of very large-tonnage truck-mounted cranes and all-terrain cranes, enabling the rotation of the crane's upper works under full load.

Renewable Energy: Increasingly vital in the yaw systems of the largest offshore wind turbines, where they must withstand colossal wind-induced moments and loads in harsh marine environments for decades.

Tunnel Boring: Used in the main bearing assemblies of large tunnel boring machines (TBMs), supporting the enormous thrust and rotational forces required to drive the cutting head through rock and soil.

Other Heavy Industry: Applications include large radar platforms, heavy-duty industrial turntables, specialized material handling equipment in foundries, and any machinery where extreme stability under immense combined loads is critical.

Factors Influencing Three Row Roller Slewing Bearing Price

The price of a Three Row Roller Slewing Bearing is significantly higher than simpler bearing types due to its complexity, material requirements, and manufacturing precision. Key factors driving cost include:

Bearing Size and Dimensions: Diameter, width, and overall dimensions are primary cost drivers. Larger bearings require vastly more raw material (high-grade alloy steel) and involve larger, more complex machining processes. Ring thickness and roller dimensions directly scale with size.

Load Capacity Requirements: Higher specified axial, radial, and moment load ratings necessitate larger cross-sections, wider rollers, more rollers, enhanced heat treatment processes, and potentially more robust cage designs – all increasing material usage and manufacturing time.

Material Specification: The grade and quality of the forged or rolled alloy steel (e.g., 42CrMo, 50Mn) used for rings and rollers are critical. Higher strength, cleaner steels with better fatigue properties command premium prices. The volume of material required is substantial.

Heat Treatment Complexity: Achieving the deep (3-6mm), hard (HRC 55-60) surface layer on large, complex raceways via medium-frequency induction hardening is a sophisticated and energy-intensive process requiring precise control. Gear tooth hardening adds further complexity and cost.

Precision Machining Tolerances: Manufacturing the rings to the extremely tight geometric tolerances required for proper roller path alignment and load distribution demands advanced CNC machining centers, skilled operators, and rigorous quality control, significantly impacting production time and cost. Roller precision is equally critical.

Gearing: Adding external or internal gearing substantially increases complexity. Gear cutting (hobbing, shaping), tooth profile grinding, and the specialized hardening processes required (scanning quench, M/F quenching) add considerable cost. Larger gear modules or hardened teeth increase this further.

Cage Design and Material: The cage must be robust enough to handle the high loads and guide the rollers precisely. Designs using high-strength brass, special polymers, or precision-machined steel segments add cost compared to simpler pressed steel cages.

Sealing System: Effective sealing for harsh environments (multiple lip seals, labyrinth features, special elastomers) adds cost. Requirements for grease purging or monitoring ports also contribute.

Lubrication System: Integrated lubrication channels, fittings, and potentially centralized lubrication systems add to the complexity and price.

Customization: Bearings designed to specific, non-standard dimensions, load cases, mounting arrangements, or special features (unusual bolt patterns, integrated sensors, special coatings) incur significant engineering and setup costs.

Quality Certifications: Meeting stringent international quality standards (ISO 9001), specific industry certifications (e.g., DNV-GL, ABS for marine), and providing extensive material and process documentation (mill certs, heat treat charts, NDT reports) adds administrative and testing overhead.

Quantity: While unit costs are high, economies of scale can apply for larger production runs, reducing the per-unit cost compared to one-off or small-batch production.

Supplier Expertise and Reputation: Established manufacturers with proven expertise in designing and manufacturing these complex bearings, backed by a strong track record and technical support, typically command a price premium reflecting their reliability and engineering capability.

Supplier of Three Row Roller Slewing Bearings

For engineers and procurement specialists sourcing critical Three Row Roller Slewing Bearings, partnering with a manufacturer possessing deep expertise and proven capability is essential. LYRADRIVE stands as a prominent supplier within this demanding sector. They focus on the design, engineering, and precision manufacturing of large-diameter slewing bearings, including the complex Three Row Roller type. LYRADRIVE typically offers comprehensive solutions, encompassing custom design services tailored to specific application loads and environments, advanced manufacturing utilizing high-grade materials and controlled heat treatment processes, stringent quality control protocols often aligned with international standards, and robust technical support throughout the project lifecycle – from initial specification to installation guidance. Their production capabilities are geared towards delivering bearings that meet the rigorous demands of industries like heavy lifting, mining, port machinery, and renewable energy, emphasizing reliability and long-term performance under extreme operating conditions. Engaging with a supplier like LYRADRIVE involves detailed technical discussions to ensure the bearing design precisely matches the application's unique requirements.