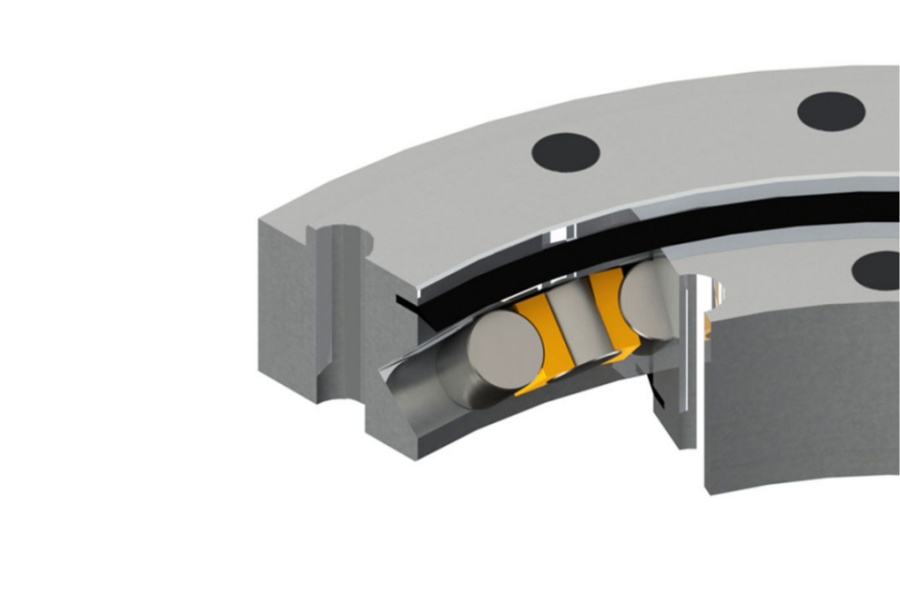

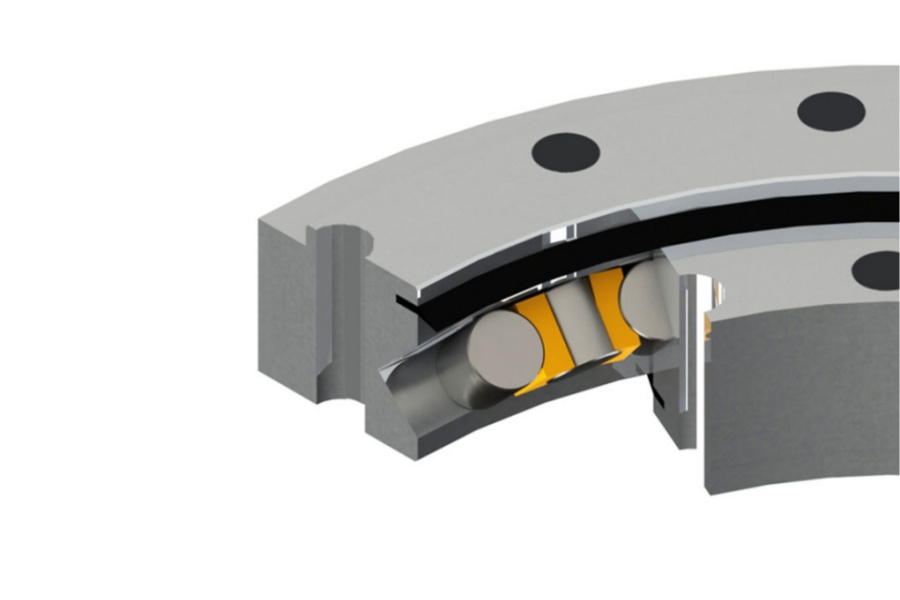

Crossed Cylindrical Roller Slewing Bearing Precision Rotation for Demanding Loads

What is Crossed Cylindrical Roller Slewing Bearing

Crossed Cylindrical Roller Slewing Bearing is a high-precision rotational component characterized by its 90° orthogonally arranged cylindrical rollers operating between hardened inner and outer rings. This configuration features alternating roller axes oriented perpendicularly to adjacent rollers within a single raceway, enabling simultaneous transmission of axial, radial, and moment loads through optimized line contact. The bearing incorporates precision-ground raceways, hardened rollers (HRC 60-65), and advanced retention systems (polyamide spacers or bronze cages), achieving rigid motion control with minimal elastic deformation. Its fundamental distinction lies in eliminating the four-point contact principle of ball bearings, replacing it with surface contact mechanics that provide superior load distribution and stiffness.

Why Elastic Washers Are Excluded in Slewing Bearing Bolt Installations

The prohibition against elastic washers (split lock washers, spring washers) in slewing bearing mounting stems from critical engineering principles:

Preload Stability Requirements

Elastic washers compress under load, causing unpredictable preload relaxation (15-30% torque loss) that compromises joint integrity under cyclic stresses

Stress Concentration Risks

Sharp washer edges create localized stress peaks exceeding 2x material yield strength, initiating microcracks in flange interfaces

Parallelism Degradation

Non-uniform washer compression induces flange misalignment (≥0.05mm/m), distorting bearing raceways and accelerating wear

Vibration Amplification

Elastic elements resonate at 200-800Hz frequencies, amplifying structural vibrations by 40-60%

Recommended Installation Methodology:

Direct Hardened Surface Contact: Bolt heads/nuts bear directly on ground surfaces (Ra≤3.2μm)

Precision Torque + Angle Control: Initial torque (e.g., 70% target) followed by precise angular tightening (e.g., 90° rotation)

Hydraulic Tensioning: Achieves ±2% preload accuracy for diameters >2m

Thread Locking Compounds: Anaerobic adhesives (Loctite 263) prevent loosening without compliance

Flange Design Optimization: Integrated dowel pins maintain concentricity within 0.01mm TIR

Characteristics of Crossed Cylindrical Roller Slewing Bearings

These bearings redefine precision through advanced mechanical design:

Orthogonal Roller Geometry

90° crossed rollers provide uniform load distribution, increasing moment stiffness 3x versus ball bearings

Zero-Clearance Preload

Factory-set negative clearance (0-5μm) eliminates operational backlash for micron-level repeatability

Ultra-Precision Raceways

Hardened surfaces (HRC 60-64) ground to ≤0.001mm roundness tolerance

High-Density Rolling Elements

30-40% more rollers per diameter unit versus conventional designs, boosting dynamic capacity 1.8x

Minimal Elastic Deformation

≤5μm deflection under 10kN load maintains positioning accuracy

Thermal Stability

Coefficient-matched materials maintain preload within 2% from -30°C to +80°C

Custom Configuration Options

Gear integration (DIN 1-4 accuracy), vacuum-compatible lubricants, non-magnetic variants

Applications of Crossed Cylindrical Roller Slewing Bearings

Mission-critical rotation across technology sectors:

Semiconductor Manufacturing

Lithography wafer stages requiring ≤±0.001° angular accuracy

Medical Imaging Systems

CT gantries with <10μm rotational deviation per revolution

Precision Metrology

CMM rotary tables achieving 0.1 arc-second resolution

Aerospace & Defense

Satellite antenna positioning (0.005° pointing accuracy)

Industrial Robotics

Articulated arm joints with 10,000+ hour MTBF

Optical Instrumentation

Telescope mounts compensating for 0.05" atmospheric distortion

High-Rigidity Machine Tools

5-axis CNC rotary tables handling 15,000N cutting forces

Price Determinants for Crossed Cylindrical Roller Slewing Bearings

Cost drivers reflect extreme precision requirements:

Geometric Tolerances

±0.0005° raceway perpendicularity adds 40% cost versus commercial grade

Roller Precision

Grade I rollers (0.3μm diameter tolerance) cost 5x more than Grade III

Material Certification

Vacuum-remelted 100Cr6 steel increases material cost 120%

Thermal Stabilization

Cryogenic treatment (-196°C) adds 15% processing cost

Retention System

Bronze cages cost 3.5x polyamide spacers but enable +80°C operation

Testing & Validation

ISO 10791-7 compliance testing adds 18-25% to base price

Specialized Coatings

MoS₂ dry-film lubrication increases cost 30% but eliminates grease

Crossed Cylindrical Roller Slewing Bearing Supplier

LYRADRIVE manufactures aerospace-grade Crossed Cylindrical Roller Slewing Bearings featuring ≤0.5μm raceway parallelism and custom preload settings (0-25μm negative clearance). Utilizing vacuum-degassed 100CrMo7 steel hardened to HRC 62±1, LYRADRIVE bearings achieve 30% higher dynamic load ratings than ISO 76 standards. Proprietary orthogonal grinding technology ensures <0.001mm/m raceway distortion. The company provides application-specific solutions including ultra-high vacuum variants (<1x10⁻⁹ mbar), non-magnetic options (μᵣ<1.05), and integrated absolute encoders.