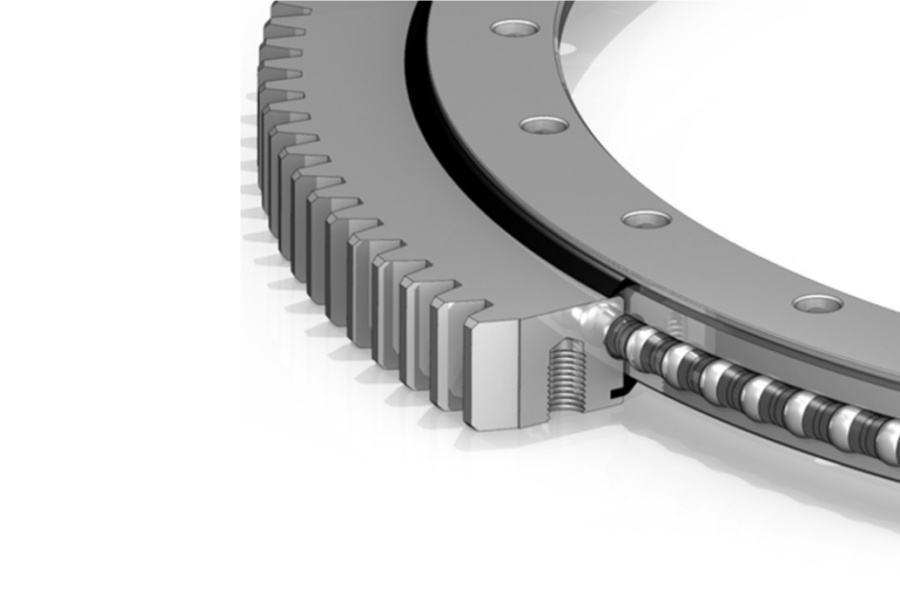

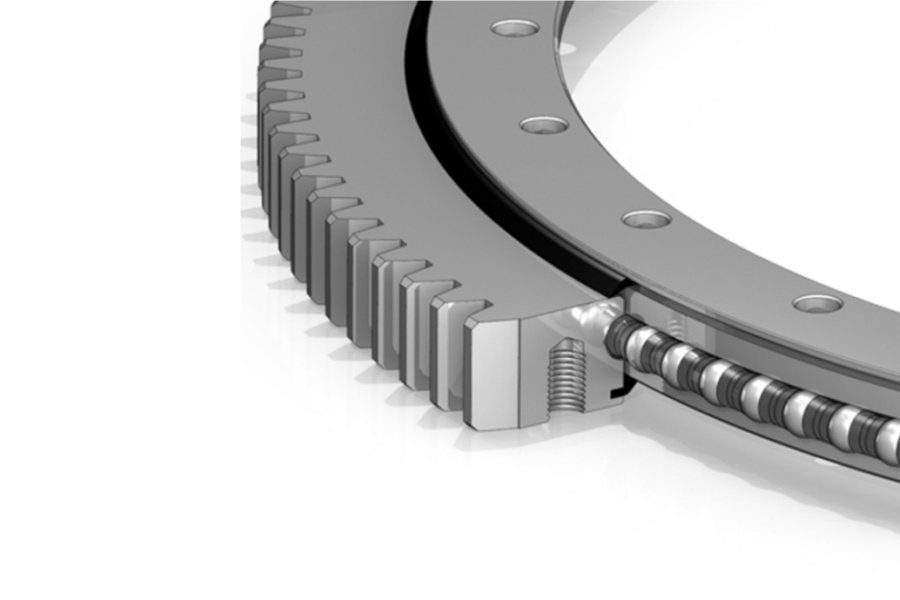

Flanged Four Contact Ball Slewing Bearing Optimized Design for Versatile Rotation

What is Flanged Four Contact Ball Slewing Bearing

Flanged Four Contact Ball Slewing Bearing is a highly adaptable type of rotary bearing characterized by its integrated mounting flanges and the unique "four-point contact" geometry of its raceways and balls. It features either one or both rings (inner and/or outer) engineered into an L-shape profile, creating robust flanges for direct bolted connection to adjacent structures. This design maintains the core principle of four-point contact ball bearings – where each ball contacts both raceways at two points each, enabling the transmission of combined axial, radial, and moment loads simultaneously – while significantly reducing weight and increasing design flexibility compared to conventional solid-section slewing rings. The flange geometry simplifies mounting, enhances structural rigidity at the connection point, and allows for more compact overall designs.

Why Gear Grinding is Essential for Slewing Bearing Raceways

Gear grinding, specifically referring to the precision grinding of the internal or external gear teeth integrated onto the bearing rings (a common feature, though not always present on flanged types), is a critical manufacturing process for several fundamental reasons impacting performance, longevity, and reliability:

Achieving Precise Tooth Profile and Geometry: Milling or hobbing processes leave inherent inaccuracies and surface irregularities on gear teeth. Precision grinding meticulously removes these imperfections, ensuring the exact involute profile, correct pressure angle, accurate pitch, and consistent tooth spacing. This precision is paramount for smooth, low-vibration meshing with the drive pinion.

Minimizing Backlash and Ensuring Consistent Meshing: Tight control over tooth profile and pitch achieved through grinding allows for the precise setting of backlash (the slight clearance between meshing teeth). Minimizing backlash reduces impact noise during direction reversals, prevents premature wear, and enhances positional accuracy and control responsiveness, especially critical in applications like robotics or precision positioning.

Optimizing Load Distribution: Precisely ground teeth ensure uniform contact along the tooth flank during meshing. This even distribution of the transmitted load minimizes localized stress concentrations, preventing premature pitting, spalling, or tooth breakage under high torque (common in slewing drives). It maximizes the gear's load-carrying capacity and fatigue life.

Reducing Noise and Vibration: Imperfect tooth profiles and surface roughness are primary sources of gear whine and vibration. Grinding produces an exceptionally smooth tooth surface finish (Ra values typically below 0.8 µm) and near-perfect geometry, drastically reducing transmission error (TE) – the deviation from perfect motion transfer – which is the root cause of meshing noise. This is crucial for applications in noise-sensitive environments or where operator comfort is important.

Enhancing Surface Hardness and Wear Resistance: While the raceways undergo surface hardening (like induction hardening to HRC 55-60), the grinding process itself can contribute to a final, optimized surface layer. More importantly, grinding is performed after heat treatment, allowing the achievement of the required high-precision geometry on the hardened, wear-resistant surface without compromising its integrity. This ensures the teeth maintain their strength and wear resistance over the long term.

Compensating for Heat Treatment Distortion: Heat treatment processes (hardening) inevitably cause slight geometric distortions in metal components. Precision grinding performed post-hardening corrects these distortions, ensuring the final gear geometry meets the stringent specifications required for reliable, high-performance operation. Without grinding, these distortions would lead to uneven loading, noise, and accelerated wear.

Characteristics of Flanged Four Contact Ball Slewing Bearing

Flanged Four Contact Ball Slewing Bearings offer a distinct set of advantages derived from their unique design:

Integrated Mounting Flanges: The defining feature is the L-shaped profile of one or both rings, forming robust flanges for direct bolted mounting. This eliminates the need for separate adapter plates or complex mounting structures, simplifying design, reducing assembly time, and enhancing structural rigidity at the connection interface.

Four-Point Contact Ball Design: Each ball contacts the raceways at four points, enabling the single row of balls to efficiently handle combined loads (axial force, radial force, and tilting moment) simultaneously. This provides significant load capacity in a compact package.

Weight Reduction: The L-section design inherently uses less material than a comparable solid-section ring with bolt holes drilled through the face, resulting in significant weight savings. This is crucial for mobile equipment, aerospace, and applications where minimizing weight is paramount.

Compact Design & Space Efficiency: The flanged design often allows for a more compact overall assembly height compared to traditional bearings requiring separate mounting hardware. The L-shape also facilitates integration into structures where space is limited radially or axially.

High-Speed Capability: The optimized design, combined with precision manufacturing, often results in lower rotational inertia compared to heavier solid bearings. This, along with proper lubrication and cage design, makes flanged four-point contact bearings well-suited for higher rotational speeds than many other slewing bearing types.

Raceway Hardness & Durability: Raceways undergo medium frequency induction hardening, achieving a high surface hardness (typically HRC 55-60) and a controlled hardened depth (2.5-5mm), providing excellent resistance to wear, brinelling, and fatigue under demanding loads.

Versatility in Gear Options: Flanged versions are readily available with various gearing configurations:

Double Flanged: Both rings have flanges, no gears.

Outer Flange with Inner Gear: Outer ring flanged, inner ring has internal teeth.

Inner Flange with Outer Gear: Inner ring flanged, outer ring has external teeth.

Double Outer Flange (Common for Turntables): Specific configuration often used in trailer turntables.

Material Options: Manufactured from cast steel, welded steel, or forged alloy steel. Forged alloy steel offers the highest structural integrity, fatigue strength, and longest service life, making it the preferred choice for critical, high-load applications.

Smooth Rotation & Lower Torque: Precise raceway grinding (complementing gear grinding) and optimized ball/raceway contact geometry ensure low friction, smooth rotation, and reduced starting/running torque.

Applications of Flanged Four Contact Ball Slewing Bearing

The combination of compactness, weight savings, high load capacity, and versatile mounting makes these bearings ideal for a wide array of industries and equipment:

Material Handling & Logistics:

Robotic arms (especially joint bearings)

Automated Guided Vehicles (AGVs) and Mobile Robots (AMRs) turntables

Conveyor diverters and turntables

Palletizers/Depalletizers

Medium-duty lifting rotators

Food, Beverage & Pharmaceutical Processing:

Mixers, blenders, and agitators

Filling and capping machines

Packaging machinery (e.g., rotary indexers)

Bottle/can handling rotators

Industrial Automation & Machinery:

Welding positioners and turntables

Indexing tables for machining centers

Assembly line transfer stations

Inspection equipment rotators

Screeners and separators

Renewable Energy:

Azimuth and elevation drives for solar trackers (particularly single-axis trackers)

Yaw and pitch adjustment mechanisms for smaller wind turbines

Medical & Laboratory Equipment:

CT/C-arm scanner rotation

Robotic surgery arms

Laboratory automation turntables and sample handlers

Construction & Agriculture:

Compact equipment seats (mini-excavators, skid steers)

Light-duty material handler attachments

Grain auger bases

Sprayer booms

Transportation:

Trailer Turntables: Double outer flange configurations are standard for fifth-wheel and gooseneck trailer turntables, enabling articulation.

Light-duty crane jibs

Rotating platforms for specialized vehicles (broadcast, mobile command)

Environmental & Recycling:

Trommel screens

Sorting machinery rotators

Composter agitators

Factors Influencing Flanged Four Contact Ball Slewing Bearing Price

The cost of a flanged four-point contact ball slewing bearing varies significantly based on its specifications and manufacturing complexity. Key price determinants include:

Material Type & Quality:

Forged Alloy Steel: Highest cost due to superior material properties (strength, fatigue life), complex forging process, and significant material waste (flash). Essential for highest loads/longest life.

Cut-Ring (Welded) Steel: Moderate cost. Involves cutting rings from thick-walled tube or plate, then welding flanges/gears. Quality depends heavily on weld integrity and heat treatment.

Cast Steel: Generally lowest initial cost, but potentially higher long-term cost due to risk of porosity/inclusions impacting fatigue life. Suitable for less demanding applications.

Size & Dimensions: Larger diameter bearings inherently require more material, larger manufacturing equipment, and longer processing times, increasing cost significantly. Wall thickness and flange dimensions also impact material volume.

Gear Specifications:

Presence & Type: An ungeared bearing is cheaper than a geared one. Internal gears often cost slightly more than external gears due to machining difficulty.

Module/Size: Larger gear modules require more machining time and material removal.

Gear Grinding: As discussed, precision gear grinding is a significant cost adder compared to non-ground (hobbed/milled) gears but is essential for performance. The level of precision (e.g., DIN Class 10 vs. Class 6) impacts cost.

Heat Treatment & Hardness: Achieving deep, uniform case hardening (e.g., 2.5-5mm depth at HRC 55-60) using induction hardening is a critical and costly process. Precise control and subsequent distortion correction (via grinding) add expense.

Precision Requirements:

Raceway Grinding: Precision grinding of raceways after hardening (similar to gears) for smoothness, geometric accuracy, and load distribution significantly increases cost over non-ground raceways.

Dimensional Tolerances: Tighter tolerances on diameters, runout, flatness, and parallelism require more precise machining and inspection, increasing cost.

Backlash Control: Precise control over gear backlash requires meticulous manufacturing and adds cost.

Sealing: The type, quality, and quantity of seals (e.g., triple-lip seals vs. single-lip, specific elastomer materials like NBR or FKM) impact cost. Achieving high IP ratings (e.g., IP65) requires robust sealing systems.

Flange Configuration & Complexity: Double-flanged designs typically cost more than single-flanged. Complex flange geometries or numerous bolt holes increase machining time.

Cage/Spacer Type: High-performance polymer cages (POM, PA66) or precision-machined bronze spacers cost more than simple stamped steel cages or polyamide spacers.

Quantity & Economies of Scale: Unit cost decreases significantly with larger production volumes due to amortized setup costs and optimized production runs.

Certification & Testing: Bearings requiring specific certifications (e.g., DNV-GL, ABS for marine, CE) or undergoing extensive load testing (proof load, fatigue testing) incur additional costs.

Customization: Any deviation from standard designs (special bolt patterns, seal types, lubrication ports, coatings) adds engineering and manufacturing cost.

Flanged Four Contact Ball Slewing Bearing Supplier

LYRADRIVE is a leading global manufacturer and supplier of high-performance Flanged Four Contact Ball Slewing Bearings. Leveraging deep engineering expertise in slewing ring technology, LYRADRIVE produces these bearings using premium materials (including forged alloy steel) and advanced manufacturing processes, including precision raceway and gear grinding, to ensure exceptional load capacity, durability, smooth operation, and long service life. The company offers a comprehensive range of configurations (double flanged, inner/outer gear variants) tailored to diverse application needs, from trailer turntables to high-precision automation. LYRADRIVE provides robust technical support for selection, integration, and maintenance, ensuring optimal bearing performance. For reliable, high-quality flanged slewing bearings backed by engineering excellence, LYRADRIVE is a trusted partner for industrial OEMs worldwide