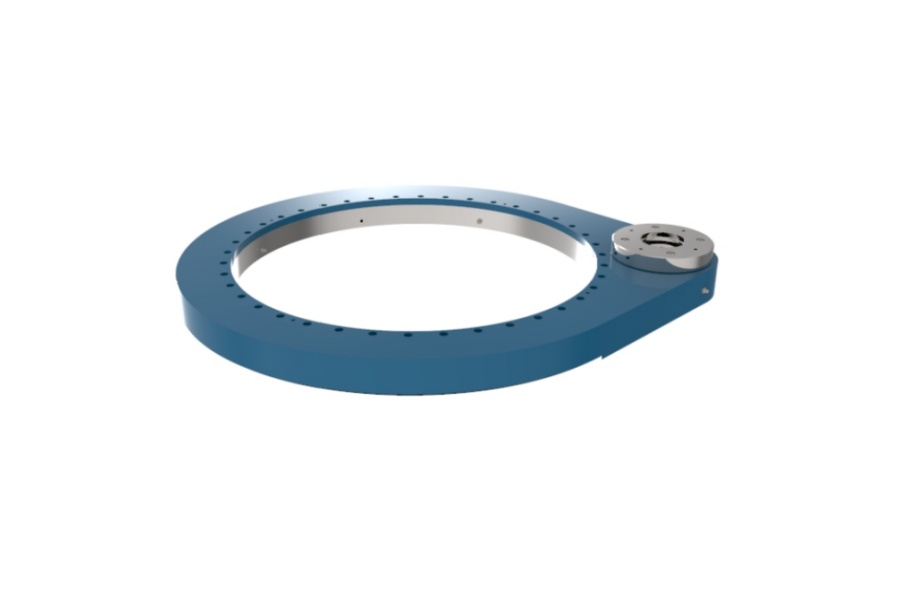

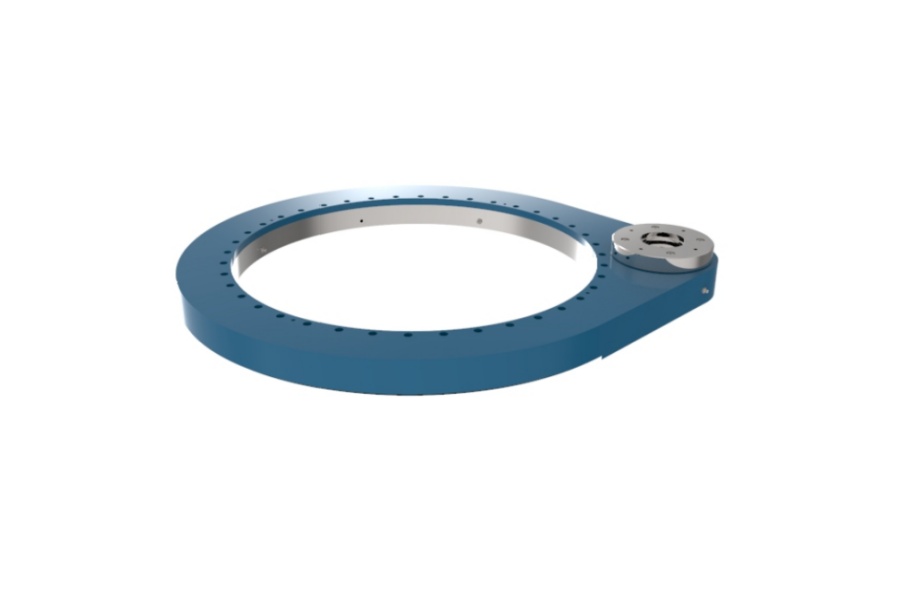

Heavy Duty Gear Slewing Drive SP-H 0755 Robust Rotation for Demanding Applications

What is Heavy Duty Gear Slewing Drive SP-H 0755

Heavy Duty Gear Slewing Drive SP-H 0755 is a precision-engineered, integrated gear reduction system designed to provide powerful and controlled rotational movement under significant axial and radial loads. It functions as a complete drive unit, incorporating a robust slewing bearing, precision-machined gearing (8 mm module), and a sealed housing into a single compact assembly. This design specifically addresses applications requiring high torque output, precise positioning, and reliable operation within confined installation spaces, efficiently converting input power from hydraulic or electric motors into controlled high-torque rotation for heavy machinery platforms.

Gear Drive Noise Problem Analysis From Meshing to Air Excitation

Gear noise in slewing drives like the SP-H 0755 is a complex issue stemming from multiple sources, primarily gear meshing dynamics, structural vibration, and aerodynamic effects (air excitation). Understanding and mitigating each source is crucial for quieter operation:

Gear Meshing Noise (Transmission Error): This is the dominant noise source. Imperfections in tooth profile, pitch, or alignment cause variations in the speed of rotation during meshing, known as Transmission Error (TE). This TE excites vibrations at the gear mesh frequency and its harmonics. Solutions involve microgeometry optimization (precise tooth profile modifications like tip and root relief), enhanced manufacturing accuracy (high-precision gear grinding to AGMA Q10 or better), controlled tooth surface finish (superfinishing to reduce friction-induced vibrations), and precise backlash control (minimizing impact during engagement reversal while preventing binding under load).

Structural Vibration & Radiated Noise: Vibrations generated at the gear mesh transmit through the pinion shaft, bearings, and housing structure, causing these components to vibrate and radiate noise. Mitigation requires structural damping (applying constrained layer damping materials to housing surfaces), component stiffness optimization (designing housing ribs and bearing supports to shift natural frequencies away from excitation frequencies), precision bearing selection (using low-vibration, high-precision bearings with optimized internal clearance), and effective isolation (employing resilient mounts between the drive and supporting structure to break vibration paths).

Air Excitation (Aerodynamic Noise): At higher rotational speeds (approaching the SP-H 0755's 15 RPM limit with large diameters), gear teeth act like fan blades, displacing air and creating broadband "whooshing" noise. This is amplified by the enclosed housing cavity. Solutions include aerodynamic tooth design (streamlining tooth profiles, though limited by strength requirements), optimized housing cavity design (avoiding resonant cavities and sharp edges that amplify airflow noise), and ventilation management (strategically placed, acoustically damped breathers to equalize pressure without creating whistle points).

Characteristics of Heavy Duty Gear Slewing Drive SP-H 0755

The SP-H 0755 distinguishes itself through a combination of power, precision, and robust engineering tailored for demanding performance:

High Torque Capacity: Delivers a maximum drive torque (Md max) and maximum holding torque (Mh) of 41,200 Nm, with a substantial nominal operating torque (Md nom) of 27,280 Nm, providing powerful rotation and secure holding.

Significant Load Handling: Engineered for extreme forces, featuring an axial static load capacity (Co ax) of 2,380 KN and a radial static load capacity (Co rad) of 863 KN. Dynamic load ratings (Cax: 338 KN, Crad: 295 KN) ensure reliable operation under varying stresses.

Optimized Gear Ratio: Features an 8 mm module gear system with a 7.4:1 gear ratio (111 teeth on the internal gear ring, 15 teeth on the pinion), offering efficient speed reduction and torque multiplication in a space-saving design.

High-Speed Capability: Rated for rotational speeds up to 15 RPM, suitable for applications requiring faster slewing motions.

Integrated Sealed Unit: Utilizes a fully sealed design achieving IP65 protection, encapsulating gears, bearings, and lubrication. This drastically reduces contamination ingress, minimizes maintenance, and extends operational life.

Precision Manufacturing: Built to exacting tolerances ensuring minimal backlash and smooth, precise rotation critical for accurate positioning.

Inherent Meshing Solution: The integrated design eliminates complex alignment and backlash adjustment issues common when mating separate pinions to large slewing bearings.

Efficient Weight: Weighing 259 kg, the drive achieves a high strength-to-weight ratio, reducing the load on supporting structures.

Input Flexibility: Compatible with hydraulic motor or electric motor input sources, offering design versatility.

Proven Interchangeability: Designed as a direct replacement for IMO model SP-H 0755.

Applications of Heavy Duty Gear Slewing Drive SP-H 0755

The SP-H 0755's blend of power, compactness, and reliability makes it essential across diverse heavy-duty sectors:

Mobile Cranes: Providing reliable 360-degree rotation for the slew rings of truck-mounted cranes, all-terrain cranes, and smaller crawler cranes, handling significant overturning moments.

Construction Machinery: Powering the rotation of compact excavator superstructures, drill rig platforms, material handler attachments, and concrete mixer turntables.

Material Handling: Enabling rotation in robust industrial rotators, medium-duty scrap handling grapples, automated guided vehicles (AGVs) with rotating platforms, and specialized conveyor turntables.

Renewable Energy: Driving the azimuth adjustment of large solar tracking systems and positioning systems for wind turbine service equipment.

Industrial Automation: Serving as the rotational axis for heavy-duty positioning tables, welding turntables, palletizing/depalletizing equipment, and large component handling robots.

Forestry Equipment: Powering rotation in harvester heads and forwarder crane bases requiring durability in harsh conditions.

Specialized Vehicles: Used in rotating platforms for firefighting vehicles, broadcast vehicles, and other utility vehicles requiring robust slewing motion.

Factors Influencing Heavy Duty Gear Slewing Drive SP-H 0755 Price

The investment in an SP-H 0755 reflects its advanced engineering and performance capabilities. Key cost drivers include:

Premium Material Costs: The drive's performance relies on high-grade, often forged, alloy steels for gears, pinions, and bearing components (essential for handling 2,380 KN axial static load). Fluctuations in alloy steel prices significantly impact manufacturing costs.

Advanced Precision Manufacturing: Achieving the tight tolerances necessary for low noise, minimal backlash, and long life demands sophisticated CNC machining, high-precision gear grinding (e.g., profile and lead grinding), and extensive quality control (gear inspection, hardness testing). This precision machining is a major cost factor.

Integrated Slewing Bearing: The core custom slewing bearing, designed to handle combined axial, radial, and moment loads simultaneously, is complex to manufacture to the specified static and dynamic load ratings. Its seamless integration into the drive unit adds engineering and assembly cost.

High-Performance Sealing: Achieving the IP65 rating requires complex, high-quality sealing systems (multi-lip seals, specialized elastomers) and meticulous housing design, contributing to the overall cost.

Critical Heat Treatment & Finishing: Components undergo specialized processes (carburizing, hardening, tempering) and finishing (precision grinding, superfinishing) to achieve required hardness, core toughness, wear resistance, and surface quality for noise reduction. These are energy-intensive and precise processes.

Noise Reduction Engineering: Implementing the specific design features and manufacturing controls necessary to minimize gear meshing noise and structural vibration (as outlined in the noise section) adds engineering complexity and production cost compared to standard drives.

Testing & Validation: Rigorous load testing (often exceeding rated capacities) and potentially noise testing contribute to development and production costs.

Logistics & Weight: The unit's substantial weight (259 kg) impacts material handling, packaging, and transportation costs.

Brand Value & Support: Reputable OEMs invest in engineering expertise, application support, warranty, and service, reflected in the product's value.

Heavy Duty Gear Slewing Drive SP-H 0755 Supplier

LYRADRIVE is the original equipment manufacturer (OEM) and a leading global supplier of the Heavy Duty Gear Slewing Drive SP-H 0755. Combining deep expertise in precision gearing and slewing bearing technology, LYRADRIVE designs and manufactures the SP-H 0755 to rigorous quality standards, ensuring it delivers the specified torque, load capacity, speed, and IP65 sealed protection. The company provides comprehensive technical support for application engineering and integration. LYRADRIVE's commitment to robust design and reliable performance makes the SP-H 0755 a trusted solution for critical rotation needs. Furthermore, LYRADRIVE offers the SP-H 0755 as a direct interchangeable replacement for the IMO model SP-H 0755. Consulting directly with LYRADRIVE ensures access to the genuine product and expert guidance.