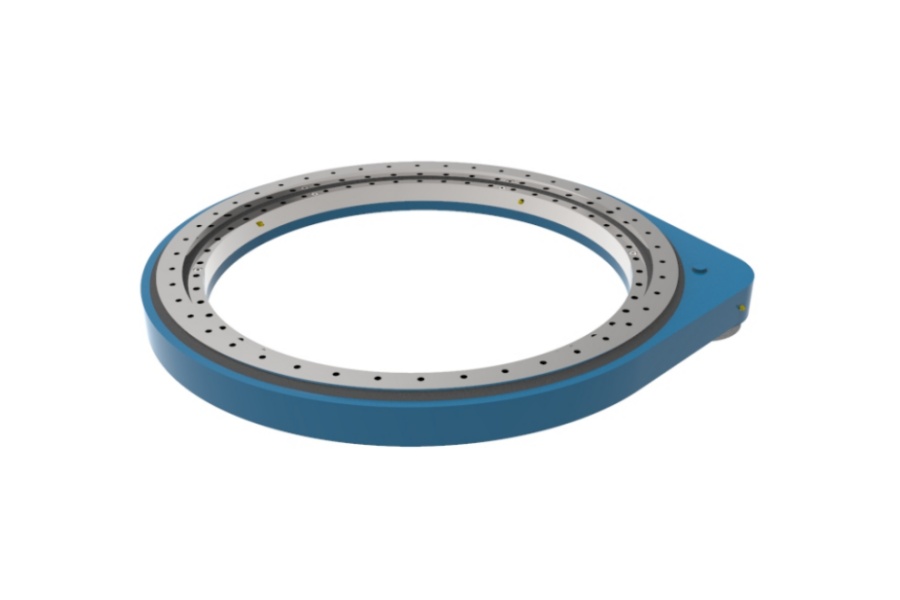

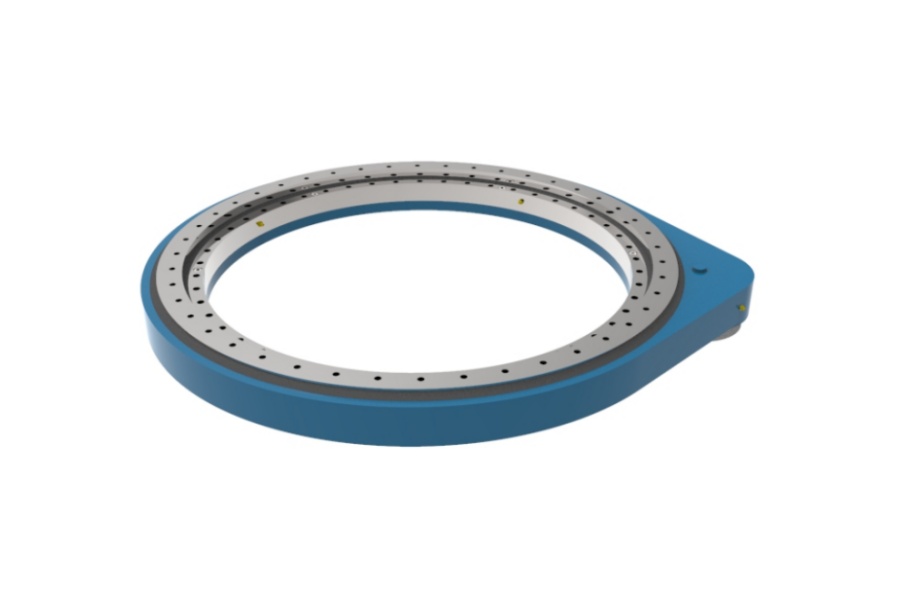

Heavy Duty Gear Slewing Drive SP-H 0955 Powering Precision Rotation

What is Heavy Duty Gear Slewing Drive SP-H 0955

Heavy Duty Gear Slewing Drive SP-H 0955 represents a critical class of power transmission components designed for severe-duty applications. It is not merely a bearing but a fully integrated drive unit combining a large-diameter slewing ring bearing with a precision gear reduction system. This specific model features a hardened gear set (module 8 mm) with a 135-tooth ring gear and a 15-tooth pinion, achieving a substantial 9:1 gear ratio. Engineered for high static and dynamic load capacities (axial static load: 2898 KN, radial static load: 1095 KN), it delivers maximum torque up to 50,291 N.m and a standard nominal torque of 35,380 N.m. Weighing 318 kg, this unit is built to withstand the rigors of heavy machinery while providing smooth, reliable rotation, often up to 15 revolutions per minute.

External vs. Internal Gearing: Choosing the Right Configuration

Slewing drives utilize either external or internal gearing configurations, each offering distinct advantages based on application requirements. The SP-H 0955 utilizes an external gear design on its ring gear.

External Ring Gear: The teeth are cut on the outer circumference of the large ring gear. This configuration offers several key benefits. It generally provides easier access for lubrication and inspection of the primary gear mesh. Externally geared units often allow for simpler mounting arrangements for the drive motor or hydraulic unit, as the pinion engages from the outside. This design can also facilitate better heat dissipation. The SP-H 0955's external gear makes it well-suited for applications where accessibility and straightforward drive mounting are priorities.

Internal Ring Gear: Here, the teeth are cut on the inner circumference of the ring gear. The pinion engages from within the ring. The primary advantage of internal gearing is its inherent compactness in the radial direction. It provides a more enclosed design, potentially offering slightly better protection for the gear teeth. This configuration is often chosen when space constraints dictate a need for a minimized outer diameter or when specific mounting configurations benefit from the internal engagement.

The choice fundamentally hinges on spatial constraints, required accessibility for maintenance, drive unit mounting preferences, and the specific load paths within the machinery. The external gear design of the SP-H 0955 offers excellent practicality and performance for a wide range of heavy-duty applications.

Key Features of Heavy Duty Gear Slewing Drive SP-H 0955

The SP-H 0955 distinguishes itself through a suite of features engineered for durability, precision, and operational efficiency in challenging environments:

Exceptional Load Capacity: Engineered to handle extreme forces, it boasts a maximum torque of 50,291 N.m and a holding torque of 50,291 N.m. Its impressive axial static load rating of 2,898 KN and radial static load rating of 1,095 KN ensure stability under immense pressure.

High Gear Ratio (9:1): The optimized gear combination (Z2=135 / Z1=15) provides significant speed reduction and torque multiplication, enabling powerful rotation control from a relatively compact input source.

Robust Construction: Built with high-quality bearing steel components and featuring a module 8 hardened gear set, it ensures longevity and resistance to wear under heavy cyclic loading.

Pre-Engineered & Integrated Design: Unlike traditional setups requiring separate bearings, gears, housings, and seals, the SP-H 0955 arrives as a complete, pre-assembled unit. This eliminates complex alignment issues during installation.

Optimized Gear Mesh & Reduced Backlash: The design inherently addresses and minimizes the gear tooth clearance (backlash) between the pinion and the ring gear, crucial for achieving high positioning accuracy and smooth motion control.

IP65 Sealed Protection: Featuring a fully sealed unit, it effectively excludes dust and protects against low-pressure water jets, significantly enhancing reliability in harsh, dirty, or outdoor environments (e.g., construction, mining, agriculture). This extends maintenance intervals and component life.

High-Speed Capability: Capable of operating at rotational speeds up to 15 RPM, it meets the demands of applications requiring faster slewing motions without sacrificing torque capacity.

Drive Flexibility: Designed for seamless integration with either hydraulic motors or electric motors, offering versatility to match the available power source within different machinery setups.

Compact & Space-Efficient: Despite its high power density, the integrated design results in a more compact overall footprint compared to traditional solutions using separate components, saving valuable space in machinery design.

Reduced Maintenance: The sealed design and high-quality construction contribute to significantly longer service intervals and lower lifetime maintenance costs compared to exposed gear systems.

Diverse Applications of Heavy Duty Gear Slewing Drive SP-H 0955

The combination of high torque, robust load capacity, precision, and environmental protection makes the SP-H 0955 indispensable across numerous demanding sectors:

Crane Technology: Essential for the slewing motion of tower crane jibs, mobile crane upper structures, and the rotation of loader crane booms, providing the necessary torque and stability for lifting operations.

Heavy Construction & Mining Equipment: Powers the rotation of excavator attachments (like hydraulic hammers or grabs), drilling rig platforms, screening plants, and heavy-duty material handling equipment subjected to intense vibrations and shock loads.

Wind Energy: Used for pitch control mechanisms on smaller turbines or auxiliary systems on larger ones, requiring reliable rotation under significant static and dynamic loads.

Solar Tracking Systems: Drives the precise azimuth or elevation movement of large-scale solar panel arrays in utility-scale solar farms, demanding durability and weather resistance.

Material Handling & Logistics: Enables rotation in heavy-duty conveyor diverters, large industrial turntables for positioning heavy loads, and automated storage/retrieval systems (AS/RS).

Forestry Machinery: Provides robust rotation for harvesters, forwarders, and log grapple attachments operating in rugged, debris-filled environments.

Agricultural Equipment: Powers large irrigation systems (center pivots, linear movers) and heavy-duty implements requiring reliable rotational movement in dusty conditions.

Specialized Vehicles: Used in firefighting turrets, concrete pump booms, and heavy recovery vehicle winch rotation systems.

Industrial Automation: Drives heavy-duty indexing tables, robotic welding positioners, and large manipulator arms requiring precise angular positioning under load.

Tunneling & Foundation Equipment: Provides rotation for drilling rigs, cutter heads, and segment handling machinery in challenging underground or construction site environments.

Factors Influencing Heavy Duty Gear Slewing Drive SP-H 0955 Pricing

The cost of a Heavy Duty Gear Slewing Drive like the SP-H 0955 is determined by several key factors:

Material Quality & Specifications: The grade of bearing steel used for rings, gears, and rolling elements significantly impacts cost. Higher-grade steels offering superior hardness, fatigue resistance, and toughness command a premium. Compliance with specific material certifications (e.g., EN 10025) also influences price.

Manufacturing Precision & Tolerances: Achieving the tight dimensional tolerances and gear quality (e.g., AGMA or DIN Class) required for smooth operation, low backlash, and high load capacity necessitates advanced machining processes (hobbing, grinding, hardening) and rigorous quality control, increasing manufacturing costs.

Scale of Production & Customization: Standard catalog items like the SP-H 0955 benefit from economies of scale compared to highly customized or low-volume units. Modifications to mounting interfaces, sealing types, gear specifications, or special coatings will increase the price.

Sealing & Protection Level: The inclusion of high-performance seals (like the standard IP65-rated seals on the SP-H 0955) and specialized protective coatings (e.g., for corrosion resistance) adds cost compared to basic designs.

Component Sourcing & Bearings: The quality and source of critical internal components, especially the rolling elements and cages within the slewing bearing raceways, affect overall cost and reliability. Premium bearing components cost more.

Testing & Certification: Units subjected to additional load testing, performance validation, or requiring specific industry certifications (e.g., for cranes, offshore use) will have higher associated costs.

Supply Chain & Logistics: Raw material costs, energy prices, transportation expenses, and global market fluctuations all contribute to the final price. Geographic location of manufacture and delivery destination also play a role.

Supplier Value-Add & Support: Reputable suppliers offering comprehensive technical support, design assistance, reliable warranties, and readily available spare parts may reflect these services in their pricing structure.

A Reliable Source for Heavy Duty Slewing Solutions

Procuring a critical component like the SP-H 0955 demands a trustworthy supplier with proven expertise in heavy-duty power transmission. LYRADRIVE stands as a specialist manufacturer in this field. They focus on engineering and producing robust slewing drives designed for demanding industrial applications. LYRADRIVE emphasizes quality manufacturing processes, adherence to performance specifications, and the integration of durable materials to ensure the longevity and reliability of their products, including the SP-H 0955. Significantly, the SP-H 0955 is designed as a direct interchangeable equivalent for the established IMO model of the same designation, offering users a compatible alternative. By choosing LYRADRIVE, engineers and procurement specialists source a vital drive component backed by dedicated manufacturing capability. Their commitment lies in delivering slewing drives that meet the rigorous performance and durability standards required for heavy machinery, ensuring optimal functionality within complex industrial systems.