Industrial Rotation Powerhouse for Extreme Load Applications

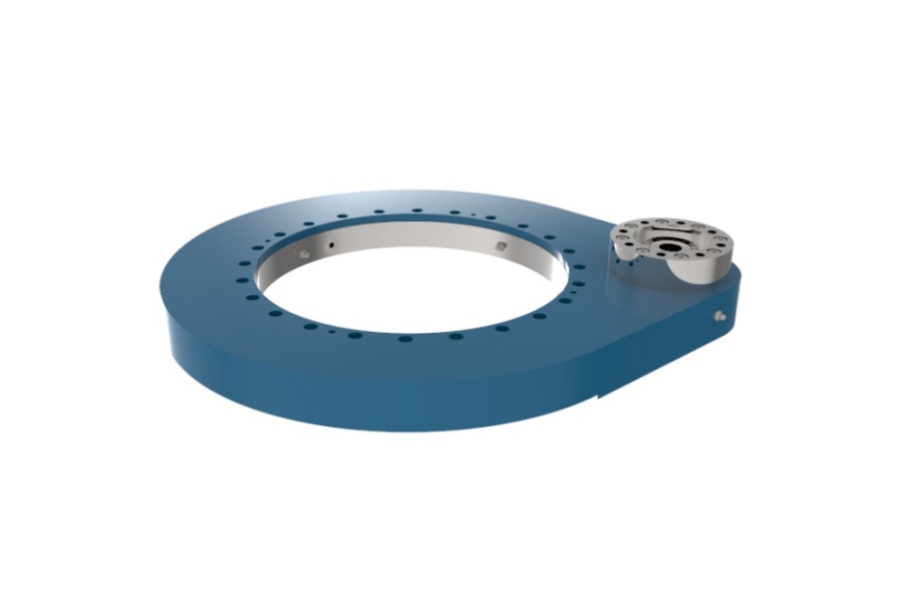

What is Heavy Duty Gear Slewing Drive SP-H 0455

Heavy Duty Gear Slewing Drive SP-H 0455 integrates industrial-grade 8-module hardened gears with a reinforced slewing bearing into a single IP65-sealed unit. This engineered solution transforms hydraulic or electric power into colossal rotational force while supporting extreme structural loads. Its optimized 72-tooth ring gear driven by a 15-tooth pinion achieves a 4.8:1 reduction ratio – enabling high-speed operation in space-constrained heavy machinery applications.

Critical Role of Lubrication in Gear Slewing Drives

Proper lubrication directly determines SP-H 0455's operational lifespan and reliability:

Wear Protection: Specialized grease forms protective films on gear teeth under extreme pressures

Corrosion Defense: Advanced additives shield components from moisture and chemical exposure

Temperature Stability: Synthetic formulations maintain performance from arctic cold to foundry heat

Contaminant Resistance: Thickened consistency traps abrasive particles before they damage surfaces

Seal Preservation: Prevents hardening and cracking of critical sealing components

Energy Efficiency: Reduces friction losses within the gear transmission system

LYRADRIDE specifies premium synthetic grease with solid lubricants for 10,000-hour service intervals

Engineering Specifications of SP-H 0455

Torque Dominance: 18,115 Nm continuous torque (27,650 Nm peak)

Structural Capacity: 1,420 KN axial static load / 530 KN radial static load

High-Speed Design: Rated for 30 RPM operation under full load

Precision Gearing: 8-module hardened helical gear system

Sealing Integrity: Triple-labyrinth sealing technology (IP65 standard)

Durability Features: Forged alloy steel components with deep case hardening

Mounting System: Heavy-duty bolt pattern for secure installation

Weight Optimization: 185 kg through advanced casting techniques

Critical Industrial Applications

Port Equipment: Container crane rotation systems and ship loader drives

Mining Machinery: Bucket wheel excavators and mineral reclaimers

Construction Systems: Tunnel boring machines and piling rig turntables

Energy Infrastructure: Hydroelectric gate mechanisms and transformer positioners

Steel Production: Ladle turret drives and rolling mill equipment

Heavy Transport: Railway turntables and specialized carriers

Defense Platforms: Weapon system traversing and radar bases

Price Determination Factors

Material Selection: Premium alloy steels for gears and bearings

Manufacturing Complexity: Precision forging and heat treatment processes

Quality Standards: Gear grinding to aerospace-grade tolerances

Testing Requirements: Extended validation under extreme conditions

Protection Systems: Advanced sealing solutions for harsh environments

Certification Needs: Industry-specific compliance documentation

Custom Engineering: Application-specific modifications

Order Volume: Production scale efficiencies

Global Logistics: Oversized component transportation

Technical Support: Comprehensive service packages

Supplier of Heavy Duty Slewing Drives

LYRADRIVE designs and manufactures the SP-H series for extreme-duty industrial applications. Their certified production facility combines advanced forging technology with precision machining capabilities. With global technical support networks and extended performance warranties, LYRADRIVE delivers engineered rotation solutions for critical infrastructure projects worldwide.