High-Capacity Precision Rotation for Demanding Industrial Applications

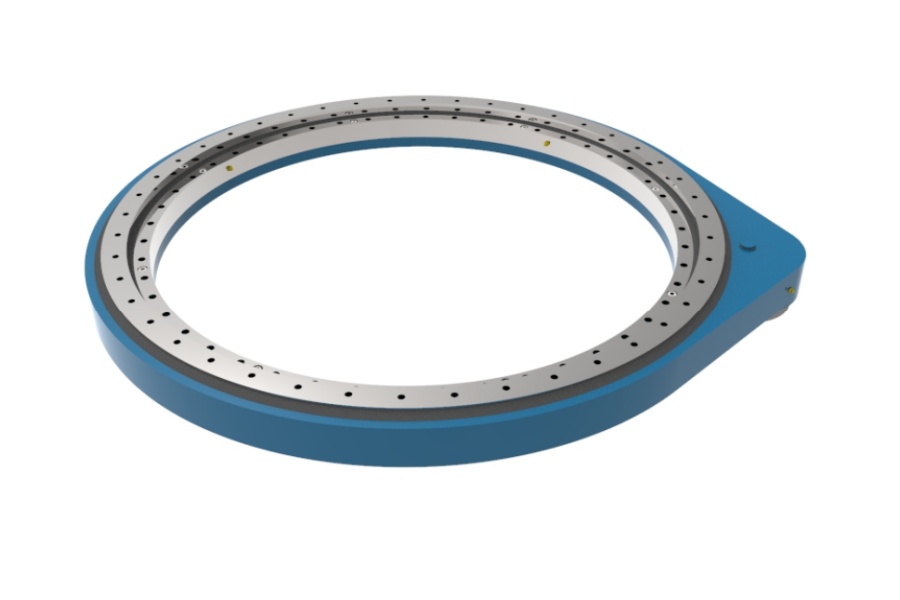

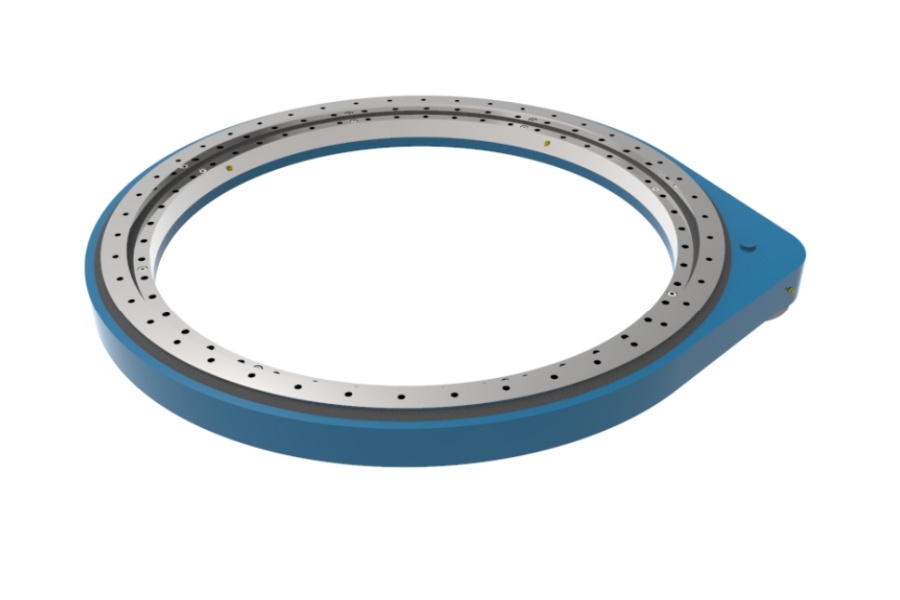

What is Medium Duty Gear Slewing Drive SP-M 1091

Medium Duty Gear Slewing Drive SP-M 1091 integrates hardened helical gearing (Module 6) with a large-diameter slewing bearing into a single IP65-sealed assembly. Engineered for 24/7 operation, this unit transforms high-speed motor input into controlled high-torque rotation (24,250 Nm max) while supporting extreme combined loads (1,503 KN axial static). Its optimized 198-tooth ring gear meshing with a 15-tooth pinion achieves a 13.2:1 reduction ratio - the steepest in its class - enabling precise low-speed output for heavy-duty industrial platforms.

Advantages of Powder Coating on Gear Slewing Drive Housings

Powder coating delivers critical performance benefits for SP-M 1091 housings:

Corrosion Resistance: Electrostatic-applied epoxy-polyester hybrid coatings create a chemically bonded barrier against salt spray, acids, and humidity, passing 1,000+ hours in ASTM B117 testing.

Impact Protection: 80-120μm thickness provides 3X better chip resistance versus liquid paints when subjected to flying debris in mining/construction.

UV Stability: Ceramic-enhanced pigments prevent fading and chalking in solar tracking applications with constant sun exposure.

Electrical Insulation: 10^14 Ω/cm surface resistivity prevents galvanic corrosion in marine environments.

Environmental Compliance: Zero VOC emissions during application meet EPA standards.

Aesthetic Durability: Retains color and gloss 5X longer than conventional paints under abrasion.

Thermal Tolerance: Withstands -40°C to 150°C without cracking or peeling.

Technical Specifications of Medium Duty Gear Slewing Drive SP-M 1091

Torque Performance: 18,910 Nm nominal torque (24,250 Nm peak)

Load Ratings: 1,503 KN axial static / 654 KN radial static; 238 KN axial dynamic / 220 KN radial dynamic

Precision Gearing: 6-module hardened helical gears (Z1=15, Z2=198) with <8 arc-min backlash

Efficiency: 96.2% power transmission at nominal load

Sealing: Triple-lip seals with particle exclusion channels (IP65 certified)

Weight: 195 kg optimized cast housing

Thermal Range: -30°C to +80°C ambient operation

Mounting: 12x M24 bolt holes on 600mm PCD

Critical Applications for SP-M 1091 Slewing Drives

Heavy Material Handling: Port crane boom rotation systems and mining stacker/reclaimers

Renewable Energy: Utility-scale solar tracker azimuth drives (4MW+ arrays)

Industrial Machinery: Rotary forging presses and steel coil handling turntables

Construction: Tower crane slewing rings and piling rig positioning systems

Transportation: Railway turntables and heavy-load car positioners

Defense: Missile launcher traverse mechanisms and radar pedestals

Marine: Shipboard crane rotation and offshore platform davit systems

Pricing Variables for Medium Duty Gear Slewing Drive SP-M 1091

Material Composition: 42CrMo4 alloy steel gears (+23% vs standard steel) and 100Cr6 bearing races (+18%)

Heat Treatment: Deep case hardening (1.5-2.0mm depth) adds 15% to base cost

Precision Machining: CNC grinding to AGMA 14 accuracy grade increases cost 30% vs milled gears

Powder Coating: Corrosion-resistant architectural-grade coating adds 8-12%

Certifications: CE, DNV-GL, and ISO 6336 documentation package (+9%)

Customization: Non-standard shaft configurations (splined/Taper-Lock) incur 15-25% premium

Order Volume: Tiered discounts activate at 25+ units (7% discount)

Supply Chain: Chromium/molybdenum surcharges fluctuate monthly (±12%)

Manufacturer of Medium Duty Gear Slewing Drive SP-M 1091

LYRADRIVE designs and manufactures the SP-M series slewing drives for extreme-duty applications. Their vertically integrated facility in Jiangsu, China features robotic machining cells and Class 10K cleanrooms for precision assembly. Holding ISO 9001:2015, AS9100D, and DNV-GL certifications, LYRADRIVE provides technical support for drive integration across six continents, offering 24-month performance warranties on all SP-M units.