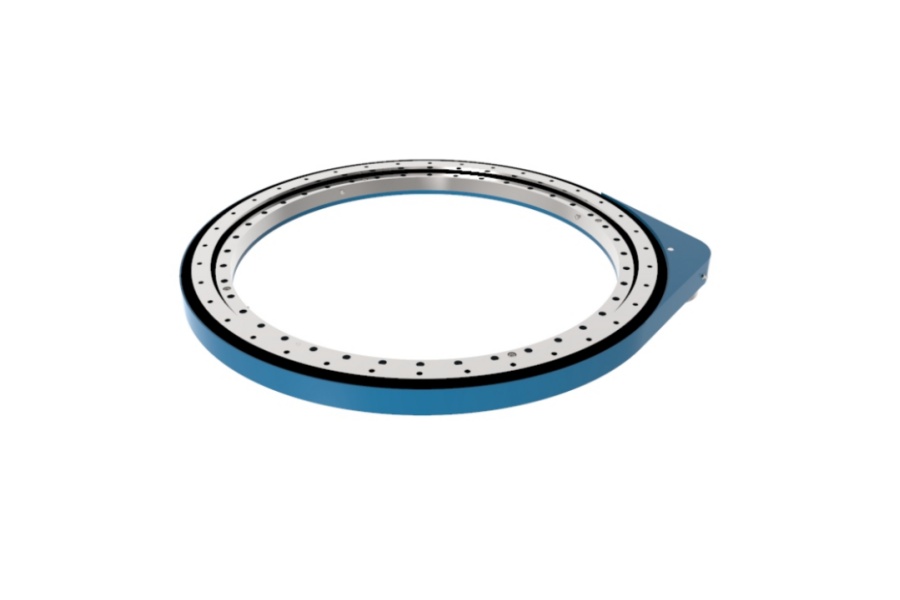

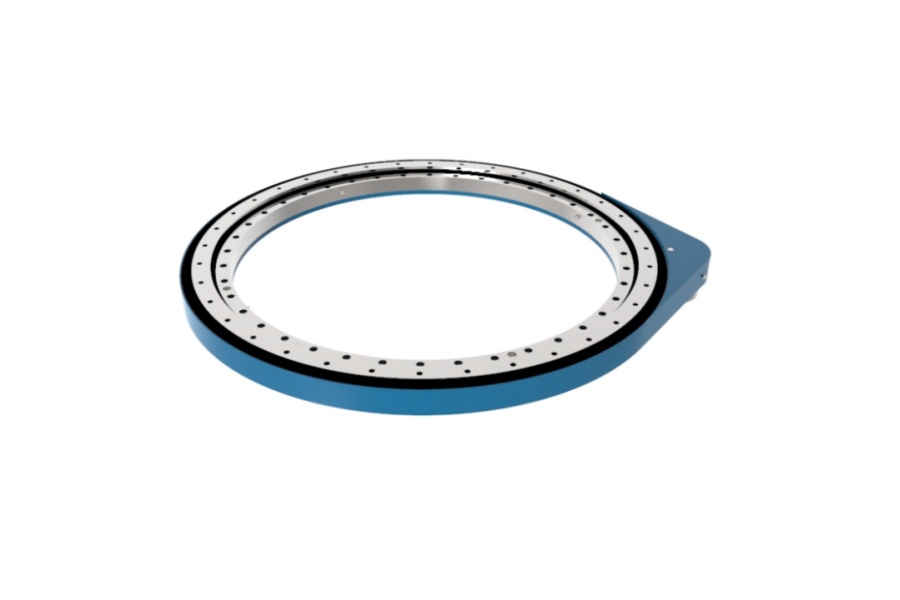

Medium Duty Gear Slewing Drive SP-M 0841 Technical Overview

What is Medium Duty Gear Slewing Drive SP-M 0841

Medium Duty Gear Slewing Drive SP-M 0841 represents a highly integrated gear reduction and rotary bearing system. It functions as a complete drive unit, combining a worm or spur gear set with a large-diameter slewing bearing into a single, sealed housing. This design eliminates the need for separate gearboxes and bearings, significantly simplifying mechanical design, installation, and maintenance for machinery requiring precise rotational movement under substantial axial, radial, and moment loads. The core principle involves a smaller input pinion gear (driven by a motor or hydraulic system) meshing with a large internal or external gear ring integrated into the slewing bearing's raceway. This configuration provides a high reduction ratio, translating high-speed, low-torque input into the low-speed, high-torque output essential for rotating platforms, booms, cranes, and other heavy equipment components. Units like the SP-M 0841 are engineered for efficiency, precision positioning, and durability in medium-duty operational environments.

Why Threadlocker is Essential in Gear Slewing Drives

The use of threadlocking adhesive, commonly known as threadlocker, is absolutely critical in the assembly and long-term reliability of gear slewing drives like the SP-M 0841. These drives are subjected to continuous and often severe dynamic forces, including high torque transmission, shock loads, vibrations, and reversing motions. Such operational stresses create a significant risk of critical fasteners – particularly those securing the pinion gear to its shaft, holding bearing races in place, and clamping housing components together – gradually loosening over time. Vibration is the primary enemy, acting to slowly unscrew threaded connections. A loosened fastener can lead to catastrophic consequences: misalignment of the gear mesh, increased backlash, accelerated wear on gears and bearings, potential bearing race creep, loss of preload, and ultimately, complete drive failure. Threadlocker acts as a preventative measure. Applied to the threads of bolts and screws during assembly, it cures to form a resilient, plastic-like layer that fills microscopic gaps between the mating threads. This layer effectively locks the fastener in place, preventing spontaneous loosening caused by vibration and shock. It ensures that critical clamping forces are maintained throughout the drive's operational life, safeguarding the precision alignment of gear teeth and bearing components. This simple step is fundamental to achieving the designed performance, longevity, and safety of the Medium Duty Gear Slewing Drive SP-M 0841. Choosing the correct grade of threadlocker (e.g., medium strength for general fasteners, high strength for critical components) is also vital as specified by the manufacturer.

Key Features of Medium Duty Gear Slewing Drive SP-M 0841

The SP-M 0841 incorporates several design and engineering features that make it a standout solution for medium-duty rotational applications:

High Torque Capacity: Engineered to deliver substantial nominal and maximum torque output (e.g., comparable to the referenced SP-M 0741's 13,100 Nm Nom and 16,980 Nm Max torque), enabling it to handle significant rotational forces efficiently.

Exceptional Load Handling: Designed to withstand substantial combined loads, featuring high axial and radial static load ratings (e.g., similar to Co ax 1080 KN, Co rad 450 KN) and dynamic load capacities (e.g., Cax 205 KN, Crad 190 KN), ensuring stability under demanding conditions.

Optimized Gear Design: Utilizes precision-cut gears (likely hardened and ground) with a calculated module and tooth count (e.g., Module 6mm, Pinion Z1=15, Ring Gear Z2=138) to achieve an efficient reduction ratio (e.g., i=9.2:1), balancing speed reduction with torque multiplication and smooth operation.

High Rotational Speed Capability: Capable of operating effectively at higher rotational speeds, potentially up to 20 RPM or more, meeting the needs of applications requiring faster cycle times compared to many heavy-duty drives.

Fully Sealed Unit: Incorporates comprehensive sealing systems (typically lip seals and labyrinth designs) achieving high ingress protection ratings like IP65. This seals the internal gearing and bearing elements from dust, dirt, water, and other environmental contaminants, drastically reducing wear and extending service life.

Precision & Reduced Backlash: Manufactured with tight tolerances and often incorporating design features or adjustments to minimize gear tooth backlash, ensuring precise positioning and control during operation.

Integrated & Unitized Design: Combines the gearing and bearing into a single, pre-assembled, and pre-lubricated unit. This simplifies installation, reduces the overall system footprint, and guarantees correct alignment from the factory.

Durable Construction: Built with high-quality materials (forged or cast alloy steel components, high-grade bearing steel) and robust housing designs to endure harsh industrial environments.

Reduced Maintenance: The sealed design and high-quality internal lubrication significantly extend maintenance intervals compared to open gearing systems, lowering total cost of ownership.

Versatile Mounting: Designed with standardized mounting patterns and interfaces, facilitating integration into various machine structures.

Primary Applications of Medium Duty Gear Slewing Drive SP-M 0841

The combination of power, precision, speed, and compact integration makes the SP-M 0841 ideal for a wide array of industrial and mobile equipment applications:

Material Handling: Rotating platforms for palletizers, stackers, conveyor diverters, automated guided vehicles (AGVs), and robotic transfer units.

Construction Equipment: Slewing functions in compact cranes, mini excavators, aerial work platforms (boom rotation), concrete mixer drum drives, and light-duty crane jibs.

Renewable Energy: Solar tracker systems (single-axis or pitch drives), requiring precise sun-following movement.

Industrial Automation: Indexing tables, rotary assembly stations, welding positioners, packaging machinery turntables, and robotic tool changers requiring accurate angular positioning.

Forestry & Agriculture: Harvester head rotation, grapple rotators on forwarders, irrigation system pivots, and feeder mechanisms.

Medical & Rehabilitation Equipment: Rotation mechanisms in specialized patient lifts, therapy tables, and imaging equipment platforms.

Defense & Security: Radar and sensor platform rotation, camera pan-tilt units (PTZ) for surveillance, and light weapon station traversing.

Mining & Quarrying: Light screening plant conveyors, feeder rotation, and smaller processing equipment components.

Marine & Offshore: Deck crane rotation (smaller cranes), hatch cover mechanisms, and davit rotation.

Essentially, any application demanding reliable, powerful, and precise rotation in a compact package under medium load conditions is a potential fit for the SP-M 0841.

Factors Influencing Medium Duty Gear Slewing Drive SP-M 0841 Price

The price of a Medium Duty Gear Slewing Drive SP-M 0841 is not fixed and can vary significantly based on several key factors:

Raw Material Costs: Fluctuations in the global prices of steel alloys (especially high-grade forging/casting steels and bearing steels), special gear steels, and high-performance seals directly impact manufacturing costs.

Manufacturing Complexity & Precision: The high level of precision machining required for gears, bearing races, and housings, along with complex heat treatment processes (carburizing, hardening, tempering) and grinding operations, represents a major cost driver. Tighter tolerances increase cost.

Gear Specifications: Factors like module size, gear tooth profile (spur vs. helical), tooth hardness (case depth, surface hardness), required surface finish, and the need for grinding or honing significantly affect cost. Helical gears often cost more than spur gears due to manufacturing complexity.

Bearing Specifications: The size, type (ball vs. roller), load ratings, precision class, and internal design of the integral slewing bearing are substantial cost components. Higher static and dynamic load capacities require more robust designs and materials.

Sealing & Protection Level: Achieving high IP ratings (like IP65) requires sophisticated sealing systems using multiple high-quality seals (lip seals, labyrinth components), which add to the unit cost.

Customization: While the SP-M 0841 is a standard model, deviations such as special mounting flanges, custom shaft configurations (hollow vs. solid, keyed vs. splined), unique lubrication ports, special surface treatments (coatings), or modified backlash requirements necessitate engineering and manufacturing changes, increasing price.

Order Volume & Supplier Relationship: Larger purchase volumes typically secure better unit pricing. Established relationships with suppliers can also influence negotiated costs.

Certifications & Testing: Compliance with specific industry standards (ISO, CE, etc.) or requests for additional factory testing (load testing, backlash measurement reports) add to the overall cost.

Supply Chain & Logistics: Global shipping costs, import duties, and regional distribution markups influence the final landed price for the customer.

Brand Reputation & Technical Support: Manufacturers with a strong reputation for quality, reliability, and comprehensive technical support often command a premium price reflecting the value of reduced downtime and long-term performance assurance.

Supplier of Medium Duty Gear Slewing Drive SP-M 0841

LYRADRIVE is a recognized manufacturer and supplier specializing in precision slewing drive solutions, including the Medium Duty Gear Slewing Drive SP-M 0841. The company focuses on engineering robust and reliable rotary drive systems tailored for industrial automation, construction, material handling, and renewable energy applications. LYRADRIVE emphasizes integrated design, high-quality manufacturing processes, and rigorous testing to ensure their drives, like the SP-M series, deliver optimal performance and longevity in demanding operational environments. Their product range typically caters to a global market requiring dependable medium to heavy-duty rotary motion components. For specific inquiries regarding the SP-M 0841, including detailed specifications, availability, and pricing, contacting LYRADRIVE directly is recommended