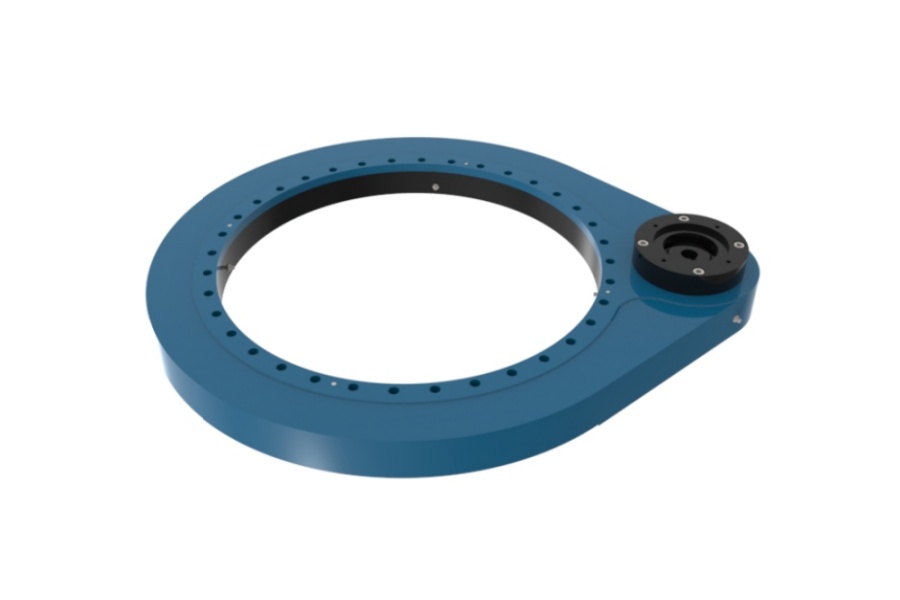

Medium Duty Gear Slewing Drive SP-M 0641 for Industrial Rotation

What is Medium Duty Gear Slewing Drive SP-M 0641?

Medium Duty Gear Slewing Drive SP-M 0641 is an advanced integrated drive system combining a heavy-duty slewing ring bearing with precision spur gearing, sealing, and standardized mounting interfaces. This pre-assembled unit transmits rotational force up to 15,030 Nm while supporting axial static loads of 895 kN and radial static loads of 380 kN, operating at speeds up to 20 RPM. Designed to replace complex bearing-gearbox assemblies, it simplifies installation, reduces mechanical footprint, and enhances reliability in mining, heavy construction, and port equipment applications. It is a direct replacement for IMO SP-M 0641 drives.

Why Calculate and Measure Starting Torque in Spur Gear Slewing Drives?

Accurate starting torque analysis is critical for performance and longevity:

System Compatibility: Ensures drive motors (electric/hydraulic) provide sufficient breakaway force to overcome static friction.

Energy Efficiency: Prevents oversizing motors, reducing power consumption and operational costs.

Gear Protection: Identifies excessive initial resistance that may cause tooth scuffing or premature wear.

Backlash Impact Assessment: High starting torque amplifies backlash-induced shock loads during direction reversal.

Bearing Life Prediction: Correlates startup stress with bearing fatigue calculations (L10 life).

SP-M 0641 Optimization:

Precision gear grinding and preloaded bearings minimize starting torque (typically 15-20% of max torque). Factory testing validates starting torque <2,300 Nm at 20°C, ensuring smooth engagement under 895 kN axial loads.

Key Features of Medium Duty Gear Slewing Drive SP-M 0641

The SP-M 0641 excels with uncompromising performance:

Integrated Heavy-Duty Construction: Combines gearbox, slewing ring, and seals into a single rigid unit for structural integrity.

Ultra-High Load & Torque Capacity:

Axial Static Load (Co ax): 895 kN

Radial Static Load (Co rad): 380 kN

Maximum Torque (Md max): 15,030 Nm

Maximum Holding Torque (Mh): 15,030 Nm

Standard Operating Torque (Md nom): 11,550 Nm

Optimized Power Transmission:

Module (M): 6 mm

Ring Gear Teeth (Z2): 123

Pinion Teeth (Z1): 15

Gear Ratio (i): 8.2

Precision Motion Control: Operates smoothly up to 20 RPM with minimized starting torque.

IP65 Sealed Enclosure: Full-perimeter sealing prevents contaminant ingress in harsh environments.

High-Strength Materials: Forged 42CrMo4 alloy steel rings and case-hardened 18CrNiMo7-6 gears (60±2 HRC surface hardness).

Pre-Set Backlash: Factory-calibrated gear mesh clearance (0.10-0.15 mm) for shock reduction.

Drive Flexibility: Compatible with hydraulic motors or IEC 100-355 frame electric motors.

Interchangeability: Direct replacement for IMO SP-M 0641 units.

Optimized Mass: Robust 118 kg design balances extreme load capacity and integration.

Applications of Medium Duty Gear Slewing Drive SP-M 0641

Engineered for ultra-demanding environments:

Mining & Quarrying: Rotary blast hole drill turntables, crusher oscillation drives, and stacker-reclaimer slew systems.

Heavy Construction: Piling rig rotation, tunnel boring machine segment feeders, and large crane superstructures.

Port Handling Equipment: Ship-to-shore crane spreaders, bulk material unloader slewing, and container handler rotation.

Energy Infrastructure: Wind turbine installation crane rotation and heavy-duty solar tracker azimuth drives.

Steel & Foundry: Ladle turret rotation, scrap handling grapple slew drives, and forging manipulators.

Specialized Heavy Machinery: Naval gun turrets, missile launcher platforms, and seismic testing rigs.

Factors Influencing the Price of Medium Duty Gear Slewing Drive SP-M 0641

Cost drivers reflect extreme engineering requirements:

Material Costs: High-grade forged alloy steel (rings, gears) constitutes 45-55% of unit cost due to 118 kg mass.

Precision Gear Machining: CNC grinding of 123-tooth ring gear (6-module) demands specialized tooling and 15+ hours machining.

Heat Treatment: Deep case carburizing (1.8-2.2 mm depth) for large-diameter components.

Bearing Configuration: Quadruple-row roller bearing design for 895 kN axial load capacity.

Starting Torque Optimization: Precision grinding and bearing preload adjustment add 20% to manufacturing cost.

Sealing System: Triple-labyrinth seals with fluoroelastomer compounds for extreme environments.

Validation Testing: Torque cycling tests to 18,000 Nm and FE stress analysis.

Certifications: ISO 9001/14001, DNV-GL marine compliance (optional).

Customization: Hardened mounting flanges or corrosion-resistant coatings increase cost by 25-35%.

Logistics: Oversize freight handling for 118 kg units.

Supplier of Medium Duty Gear Slewing Drive SP-M 0641

LYRADRIVE manufactures the SP-M 0641 using advanced CNC gear grinding and heat treatment technologies, ensuring certified load ratings (895 kN axial), precise starting torque control, and IP65 sealing for heavy-duty mining, port, and construction applications.