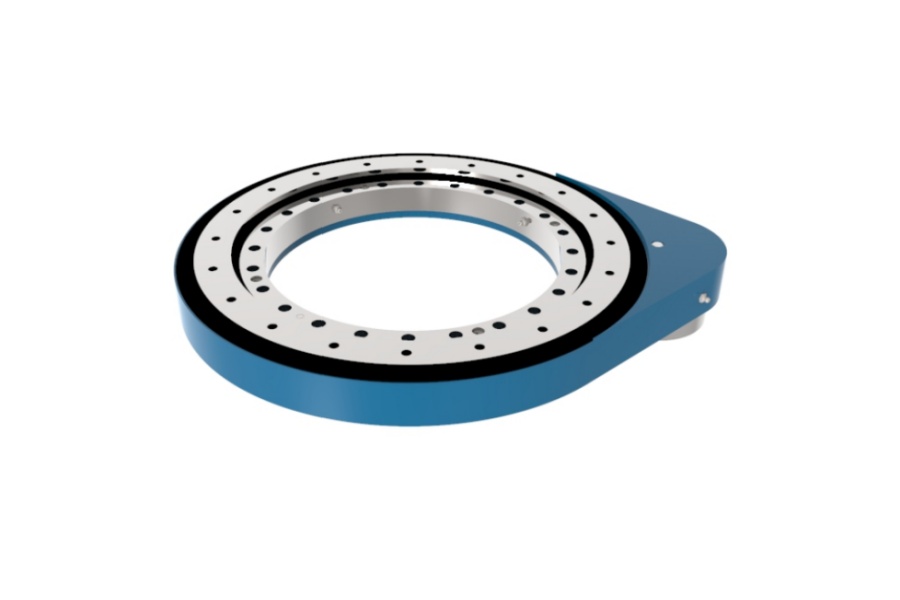

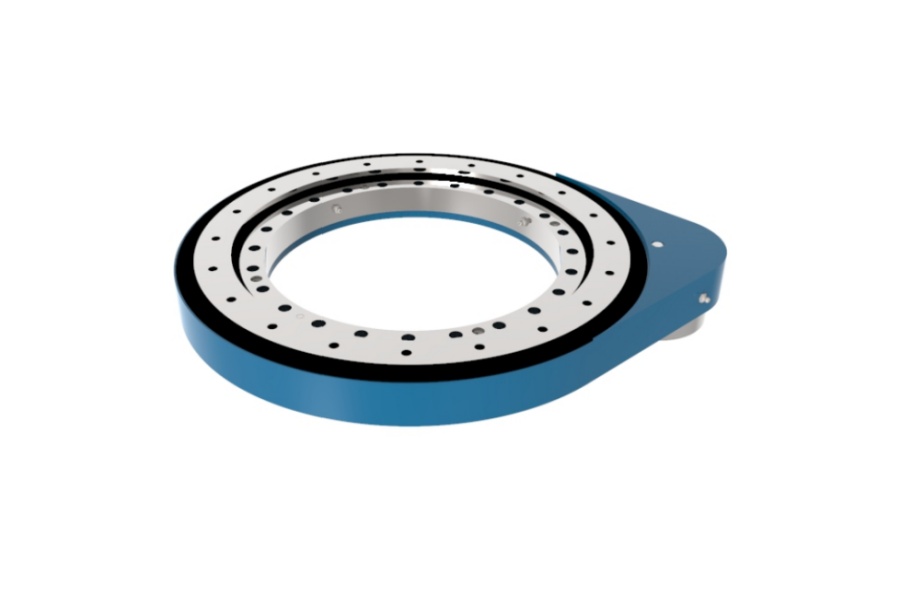

Medium Duty Gear Slewing Drive SP-M 0411 Robust Rotation Solution for Industrial Demands

What is Medium Duty Gear Slewing Drive SP-M 0411?

Medium Duty Gear Slewing Drive SP-M 0411 is an advanced integrated drive system combining a high-capacity slewing ring bearing with precision spur gearing, sealing, and mounting interfaces. This pre-assembled unit transmits rotational force up to 10,150 Nm while handling substantial static/dynamic loads (570 kN axial, 245 kN radial), achieving speeds up to 40 RPM. Designed as a direct replacement for complex bearing-gearbox-motor assemblies, it simplifies installation, reduces mechanical footprint, and enhances operational reliability in material handling, automation, and heavy equipment applications.

Gear Machining Requirements for Spur Gear Slewing Drives

Precision gear machining is critical for slewing drive performance and longevity. Key requirements include:

Tooth Profile Accuracy: Strict adherence to AGMA or ISO 1328 standards for involute profile, pitch, and runout tolerances ensures smooth meshing and load distribution.

Surface Hardness & Treatment: Case hardening (e.g., carburizing) to 58-62 HRC surface hardness with proper core toughness balances wear resistance and impact strength.

Surface Finish: Post-grinding or honing achieves Ra ≤ 0.8 μm surface finish to minimize friction, noise, and pitting risk under heavy loads.

Dimensional Consistency: CNC-controlled machining maintains exact module (6 mm) and pressure angle (typically 20°) across all teeth.

Backlash Control: Precise tooth thickness tolerancing ensures manufacturability while allowing controlled pre-set backlash (0.05-0.15 mm typical).

Material Integrity: Aircraft-grade alloy steels (e.g., 42CrMo4, 18CrNiMo7-6) with ultrasonic testing to eliminate inclusions or voids.

Heat Treatment Uniformity: Controlled atmosphere furnaces prevent decarbonization and ensure consistent hardness depth (CHD ≥ 1.0 mm).

Key Features of Medium Duty Gear Slewing Drive SP-M 0411

The SP-M 0411 excels through engineered performance:

Integrated Heavy-Duty Design: Unifies slewing ring, gearing, seals, and mounts into one rigid unit for simplified integration and structural reliability.

Enhanced Load Capacity: Engineered for demanding operations:

Axial Static Load (Co ax): 570 kN

Radial Static Load (Co rad): 245 kN

Maximum Torque (Md max): 10,150 Nm

Maximum Holding Torque (Mh): 10,150 Nm

Axial Dynamic Load (Cax): 165 kN

Radial Dynamic Load (Crad): 155 kN

Optimized Gear Transmission: Precision spur gearing configuration:

Module (M): 6 mm

Ring Gear Teeth (Z2): 84

Pinion Teeth (Z1): 15

Gear Ratio (i): 5.6

Standard Operating Torque (Md nom): 7,700 Nm

High-Speed Capability: Supports rotation up to 40 RPM for rapid-cycle applications.

Zero-Maintenance Sealing: Full-perimeter IP65 sealing protects internals from contaminants and lubricant loss.

Pre-Set Backlash: Gear mesh clearance factory-calibrated for smooth engagement and positioning repeatability (±0.1°).

Drive Flexibility: Compatible with IEC/NEMA frame motors and hydraulic drives.

Heavy-Grade Materials: Forged alloy steel rings and case-hardened gears (ISO 6336 Grade ME).

Interchangeability: Direct replacement for IMO SP-M 0411 units.

Weight Efficiency: 87 kg mass optimized for strength-to-weight ratio.

Applications of Medium Duty Gear Slewing Drive SP-M 0411

This drive excels in high-stress industrial environments:

Heavy Material Handling: Rotating crane jibs, scrap handling grapples, and bulk material reclaimers.

Construction Equipment: Drilling rig turntables, concrete pump positioning, and compact crane superstructures.

Mining & Quarrying: Screening plant oscillation, conveyor diverters, and rock breaker rotation.

Industrial Automation: Heavy-duty welding positioners (≥8 ton capacity), forging manipulators, and press feeding systems.

Energy Sector: Service platform rotation in wind turbines and solar tracker drives.

Port Equipment: Container spreader rotation and hatch cover manipulators.

Specialized Machinery: Tunnel boring machine segment feeders and military vehicle turrets.

Factors Influencing the Price of Medium Duty Gear Slewing Drive SP-M 0411

Cost drivers reflect engineering intensity:

Material Costs: High-grade forged rings (42CrMo4) and gear steel (18CrNiMo7-6) account for 35-45% of unit cost.

Precision Gear Cutting: CNC hobbing/grinding of 84-tooth ring gear (6-module) requires specialized tooling and 8+ hours machining time.

Heat Treatment: Deep-case carburizing (1.2-1.8 mm depth) for 84-tooth gear in controlled-atmosphere furnaces.

Bearing Components: Cost of large-diameter crossed roller bearings or triple-row ball elements.

Quality Validation: Gear CMM inspection (profile/pitch), torque testing to 12,000 Nm, and IP65 validation.

Sealing System: Multi-labyrinth seals with HNBR lip compounds for -40°C to 120°C operation.

Customization: Non-standard mounting flanges or shaft interfaces increase cost by 15-25%.

Certification: ISO 9001/14001 compliance documentation adds administrative overhead.

Supplier of Medium Duty Gear Slewing Drive SP-M 0411

LYRADRIVE manufactures the SP-M 0411 to exacting industrial standards, leveraging advanced CNC gear machining and heat treatment facilities to deliver drives with certified load ratings and IP65 protection. Their integrated production ensures precise backlash control and torque consistency for demanding automation and material handling applications.