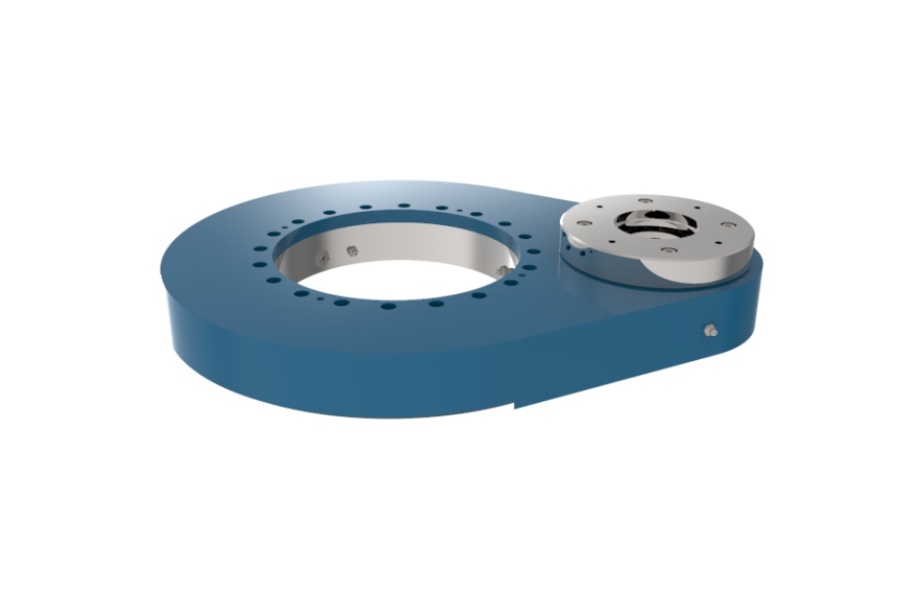

Medium Duty Gear Slewing Drive SP-M 0311 Power and Precision

What is Medium Duty Gear Slewing Drive SP-M 0311?

Medium Duty Gear Slewing Drive SP-M 0311 is a fully integrated gearbox and slewing bearing assembly designed to provide efficient rotational drive under significant axial, radial, and moment loads. It combines a high-strength slewing ring bearing with precision spur gearing, sealing, and mounting interfaces into a single pre-lubricated unit. This eliminates complex alignment, reduces mechanical footprint, and enhances system reliability for medium-duty industrial applications demanding high torque (up to 8,200 Nm) and speeds reaching 40 RPM. It serves as a direct replacement for traditional bearing-gearbox-motor assemblies, offering superior integration and performance consistency.

What Components Make Up a Spur Gear Slewing Drive?

A spur gear slewing drive like the SP-M 0311 comprises several critical components working in unison:

Slewing Ring Bearing: The core structural element featuring integrated gear teeth (typically on the outer ring). It handles combined axial, radial, and moment loads.

Pinion Gear: A precision-machined spur gear meshing with the slewing ring’s teeth, transmitting torque from the drive source.

Drive Housing/End Cap: Encloses the pinion gear and provides mounting for the drive motor (electric or hydraulic).

Sealing System: Multi-lip seals around the rotating interface and pinion shaft, preventing lubricant leakage and contaminant ingress (achieving IP65).

Rolling Elements: Balls or rollers within the slewing ring bearing raceways, enabling smooth rotation under load.

Mounting Flanges: Robust interfaces on the stationary and rotating rings for secure attachment to the machine base and superstructure.

Fasteners & Lubrication: High-strength bolts for assembly and high-performance grease for long-term lubrication of gears and bearings.

Key Features of Medium Duty Gear Slewing Drive SP-M 0311

The SP-M 0311 distinguishes itself through engineered performance and durability:

Integrated Robust Design: Combines bearing, gearing, seals, and mounts into one compact, rigid unit for simplified installation and enhanced structural integrity.

Exceptional Load Capacity: Engineered for demanding medium-duty applications:

Axial Static Load (Co ax): 430 kN

Radial Static Load (Co rad): 190 kN

Maximum Torque (Md max): 8,200 Nm

Maximum Holding Torque (Mh): 8,200 Nm

Axial Dynamic Load (Cax): 145 kN

Radial Dynamic Load (Crad): 135 kN

Optimized Power Transmission: Features robust spur gearing:

Module (M): 6 mm

Ring Gear Teeth (Z2): 69

Pinion Teeth (Z1): 15

Gear Ratio (i): 4.6

Standard Operating Torque (Md nom): 6,150 Nm

High Operational Speed: Supports rotation up to 40 RPM, enabling faster cycle times in automation and material handling.

Precision Backlash Control: Gear mesh backlash is meticulously pre-set during manufacturing, ensuring smooth operation, accurate positioning, and eliminating field adjustment needs.

IP65 Sealed Protection: Comprehensive perimeter sealing protects internal components (gears, bearings) from dust and water ingress, significantly extending service life in harsh environments.

Reduced Maintenance: Pre-lubricated for extended service intervals and protected internals minimize downtime and operational costs.

Drive Motor Flexibility: Compatible with standard electric motors (geared or direct-drive) and hydraulic motors for versatile integration.

Heavy-Duty Construction: Built for longevity under continuous stress with high-grade materials and precision manufacturing.

Interchangeability: Designed for direct replacement compatibility with IMO model SP-M 0311.

Optimized Weight: Weighs 75 kg, balancing strength for medium-duty applications without excessive mass.

Applications of Medium Duty Gear Slewing Drive SP-M 0311

The SP-M 0311’s blend of high torque, robust load capacity, and speed makes it ideal for diverse industrial sectors:

Material Handling Equipment: Slewing jib cranes, rotating forklift attachments, conveyor turntables, and automated guided vehicle (AGV) positioning decks.

Construction Machinery: Compact crane superstructure rotation, drilling rig indexing, and light excavator attachments.

Industrial Automation: Robotic welding turntables, heavy-duty indexing tables, pallet positioners, and assembly line rotating platforms.

Packaging & Processing: Rotary filling stations for heavier containers, drum handling equipment, mixer platforms, and large valve actuators.

Renewable Energy: Solar tracker azimuth drives (medium-scale) and maintenance platform rotation.

Agriculture: Irrigation system rotation, grain auger positioning, and heavy planter/seeder components.

Logistics & Warehousing: Rotating platforms for AS/RS systems, dock levelers, and container handling aids.

Specialized Machinery: Stage machinery, heavy-duty test rig rotation, and medical imaging equipment bases.

Factors Influencing the Price of Medium Duty Gear Slewing Drive SP-M 0311

The cost of the SP-M 0311 is driven by its engineering complexity and quality components:

Premium Materials: High-cost alloy steels for rings, gears (Module 6), and rolling elements, requiring specific hardness and fatigue resistance.

Advanced Precision Machining: Complex CNC machining of large-diameter integrated gear teeth on the slewing ring and precise pinion profiles demand high-tolerance equipment and skilled labor. Grinding of raceways and gear flanks adds cost.

Critical Heat Treatment: Specialized processes like case hardening are essential for gear tooth durability and bearing raceway integrity, requiring precise control.

Bearing Component Quality: Cost of high-grade rolling elements (balls/rollers), cages, and their precision manufacturing.

Backlash Control Implementation: Engineering and assembly techniques to achieve and guarantee minimal pre-set backlash add value and cost.

High-Performance Sealing: Multi-lip seals using specialized elastomers to achieve IP65 rating contribute significantly.

Corrosion Protection: Costs for surface treatments like zinc plating or specialized paints.

Rigorous Quality Control: Investment in inspection equipment and processes for gear profiling, hardness testing, noise analysis, and load testing.

Scale & Customization: Higher order volumes reduce per-unit costs. Non-standard features (special seals, coatings, mounts) increase price.

Supply Chain & Logistics: Global sourcing of materials/components, transportation, and inventory management costs.

Supplier of Medium Duty Gear Slewing Drive SP-M 0311

LYRADRIVE is a leading manufacturer specializing in high-performance slewing drives, including the reliable SP-M 0311 model. With a strong focus on engineering excellence and rigorous quality control, LYRADRIVE produces integrated drive solutions using premium materials and precision manufacturing processes. They offer comprehensive technical support to ensure optimal drive selection and integration for demanding industrial, automation, and material handling applications, backed by a commitment to reliability and customer satisfaction. Their expertise ensures the SP-M 0311 meets stringent performance and durability requirements.