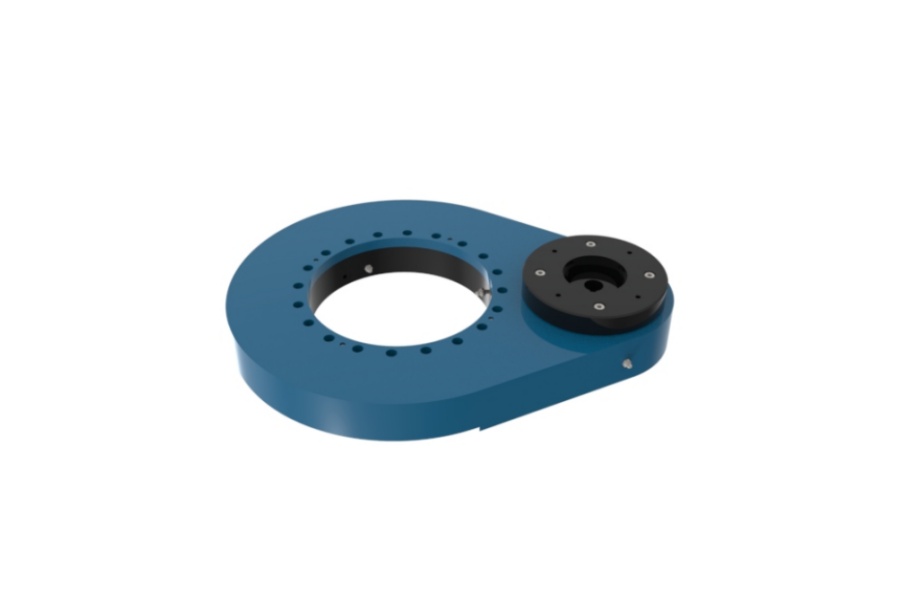

Lightweight Slewing Ring Gear Drive SP-I 0311 Optimizing Motion Where Precision Meets Power

What is Lightweight Slewing Ring Gear Drive SP-I 0311?

Lightweight Slewing Ring Gear Drive SP-I 0311 is a highly efficient, integrated gearbox and slewing ring bearing assembly. It functions as a complete rotational drive unit, designed to provide smooth, precise, and powerful rotary motion under substantial axial, radial, and moment loads. Unlike traditional setups requiring separate bearings, gears, housings, and seals, the SP-I 0311 integrates all these critical components into a single, pre-assembled, and pre-lubricated package. This unitization eliminates complex alignment procedures, reduces installation footprint, and significantly enhances overall system reliability. Primarily intended for applications demanding high-speed rotation alongside substantial load-bearing capacity, it excels in industrial automation, material handling, and specialized machinery where performance and space efficiency are paramount.

What is the Core Rotating Component of a Spur Gear Slewing Drive?

The core rotating component enabling the pivotal movement within a spur gear slewing drive like the SP-I 0311 is the slewing ring bearing. This specialized bearing is fundamentally different from standard bearings. It features integrated gear teeth machined directly onto either its inner or outer ring raceway. This design allows the bearing itself to function as the large gear (typically the ring gear) within the drive system. A smaller pinion gear, meshed with these integrated teeth, transmits torque to the bearing. When the pinion rotates, driven by a motor (electric or hydraulic), it engages with the gear teeth on the slewing ring bearing, causing the entire bearing structure – and consequently the attached platform or structure – to rotate smoothly relative to the base. The slewing ring bearing's robust construction, incorporating precisely engineered rolling elements (balls or rollers) and raceways, simultaneously handles the complex combination of axial, radial, and moment loads encountered during operation, making it the indispensable heart of the slewing drive.

Key Features of Lightweight Slewing Ring Gear Drive SP-I 0311

The SP-I 0311 distinguishes itself through a combination of advanced engineering features tailored for high performance and reliability:

Integrated Design: Combines high-precision spur gearing, a robust slewing ring bearing, seals, and mounting interfaces into a single, compact unit. This drastically simplifies machinery design, assembly, and maintenance.

High Load Capacity: Engineered to withstand significant forces simultaneously:

Axial Static Load (Co ax): 530 kN

Radial Static Load (Co rad): 200 kN

Maximum Torque (Md max): 3,580 Nm

Maximum Holding Torque (Mh): 3,580 Nm

Axial Dynamic Load (Cax): 190 kN

Radial Dynamic Load (Crad): 165 kN

High-Speed Capability: Designed for applications requiring faster rotation, supporting speeds up to 40 revolutions per minute (RPM), exceeding the capabilities of many standard slewing bearings.

Optimized Power Transmission: Features a spur gear design with:

Module (M): 4 mm

Ring Gear Teeth (Z2): 102

Pinion Teeth (Z1): 15

Gear Ratio (i): 6.8

Standard Operating Torque (Md nom): 2,540 Nm

This configuration ensures efficient power transfer and precise motion control.

Precision & Rigidity: Precision manufacturing and rigid construction minimize deflection and backlash, ensuring accurate positioning and smooth operation even under heavy loads.

Pre-Controlled Backlash: The SP series specifically addresses the critical issue of gear mesh backlash between the pinion and the integrated ring gear teeth on the slewing ring. Backlash is meticulously controlled and set during manufacturing, ensuring consistent performance and eliminating the need for complex field adjustments often associated with traditional separate bearing and gear setups.

Superior Sealing & Protection: Utilizes a comprehensive, full-perimeter sealing system that effectively encloses the critical rotating components (gears, bearing) within a sealed cavity. This design achieves a high ingress protection rating of IP65, making the unit dust-tight and protected against low-pressure water jets from any direction. This significantly enhances longevity by preventing contamination and lubricant leakage, even in harsh industrial environments.

Reduced Maintenance: The combination of high-quality seals, pre-lubrication for life (or extended service intervals), and protected internal components drastically reduces the need for frequent maintenance, lowering total cost of ownership.

Lightweight Construction: Despite its robust capabilities, the unit is engineered for weight efficiency, weighing only 42 kg. This "lightweight" characteristic is crucial for applications where minimizing overall machine weight is essential, such as mobile equipment or structures sensitive to mass.

Drive Flexibility: Offers compatibility with various prime movers, including electric motors (geared or direct-drive) and hydraulic motors, providing versatility for different power systems and application requirements.

Mounting Versatility: Designed with standardized mounting interfaces (bolt patterns) on both the rotating and stationary rings, facilitating straightforward integration into diverse machinery designs.

Applications of Lightweight Slewing Ring Gear Drive SP-I 0311

The robust performance, compact design, and high-speed capability of the SP-I 0311 make it ideally suited for a wide array of demanding industrial applications:

Industrial Automation: Robotic arms, automated welding positioners, indexing tables, pallet changers, material handling arms, and precision assembly stations requiring fast, accurate, and powerful rotation.

Material Handling Equipment: Slewing jibs, crane hooks, rotating conveyor sections, automated guided vehicle (AGV) turntables, and container handling equipment where high load capacity and reliable 360-degree rotation are critical.

Packaging Machinery: Rotary filling stations, capping machines, labeling turntables, and case/tray packers demanding high-speed, precise indexing.

Process Equipment: Mixers, agitators, rotary valves, and indexing platforms in chemical, food & beverage, and pharmaceutical processing lines.

Test & Simulation Equipment: Heavy-duty test rigs, dynamometers, flight simulators, and positioning stages requiring precise angular control under substantial loads.

Specialized Machinery: Radar and antenna positioning systems, medical imaging equipment rotation, stage machinery, and specialized manufacturing fixtures.

Logistics & Warehousing: Automated storage and retrieval system (AS/RS) cranes, rotating lift platforms, and sorting systems.

Replacing Traditional Solutions: An excellent alternative to complex custom assemblies using separate slewing bearings, external gearboxes, and motors, offering a simpler, more reliable, and space-saving solution. Its high-speed capability specifically targets applications where traditional slewing bearings might be too slow.

Factors Influencing the Price of Lightweight Slewing Ring Gear Drive SP-I 0311

The cost of an SP-I 0311 slewing drive is determined by several key factors reflecting its engineering complexity, material quality, and manufacturing precision:

Raw Material Costs & Quality: The price of high-grade alloy steel used for the rings, gears, and rolling elements significantly impacts the base cost. Fluctuations in global steel markets directly affect component pricing. The requirement for materials with specific hardness, toughness, and fatigue resistance adds cost.

Precision Manufacturing & Machining: Achieving the tight tolerances required for the gear teeth profile, raceway geometry, bearing surfaces, and overall concentricity demands advanced CNC machining centers and highly skilled operators. The complex machining processes for the integrated gear teeth on the slewing ring and the precise pinion are particularly costly. Grinding operations for raceways and gear flanks add further expense.

Heat Treatment Processes: Critical components undergo specialized heat treatment (like case hardening or through hardening) to achieve the necessary surface hardness for wear resistance and core toughness for impact resistance. Precise control of these processes is essential for performance and longevity, contributing significantly to cost.

Bearing Component Quality: The type, grade, and quantity of rolling elements (balls, rollers), cages, and the precision of their manufacturing affect both performance and price. High-grade, low-noise, long-life bearings cost more.

Pre-Controlled Backlash Implementation: The engineering effort and specialized assembly techniques required to achieve and guarantee the specified minimal, pre-set backlash between pinion and ring gear add complexity and cost compared to non-pre-set solutions.

Sealing System: The design and quality of the multi-lip seals required to achieve the IP65 rating involve specific materials (like special elastomers) and precise manufacturing, contributing to the overall cost.

Surface Treatments & Coatings: Corrosion protection (e.g., zinc plating, specialized paints) or special surface treatments on gears or raceways add processing steps and cost.

Quality Control & Testing: Rigorous in-process and final inspection procedures, including gear profile checks, hardness testing, noise/vibration analysis, and load testing, ensure reliability but require investment in equipment and time.

Order Volume & Customization: Economies of scale apply; larger orders typically benefit from lower per-unit costs. Conversely, any customization beyond the standard SP-I 0311 specification (special mounting flanges, coatings, seals, or lubrication) will increase the price.

Supply Chain & Logistics: Costs associated with sourcing high-quality components globally, transportation, and inventory management also factor into the final price.

Supplier of Lightweight Slewing Ring Gear Drive SP-I 0311

LYRADRIVE stands as a leading manufacturer and supplier of high-performance slewing drives, including the advanced SP-I 0311 model. Renowned for their engineering expertise and commitment to quality, LYRADRIVE specializes in designing and producing integrated drive solutions that meet the stringent demands of modern industrial automation, material handling, and specialized machinery. Their focus on precision manufacturing, rigorous testing, and utilizing premium materials ensures that products like the SP-I 0311 deliver exceptional reliability, durability, and performance straight from the factory. LYRADRIVE provides comprehensive technical support and works closely with customers to ensure optimal drive selection and integration for their specific application requirements, backed by a reputation for innovation and dependable supply.