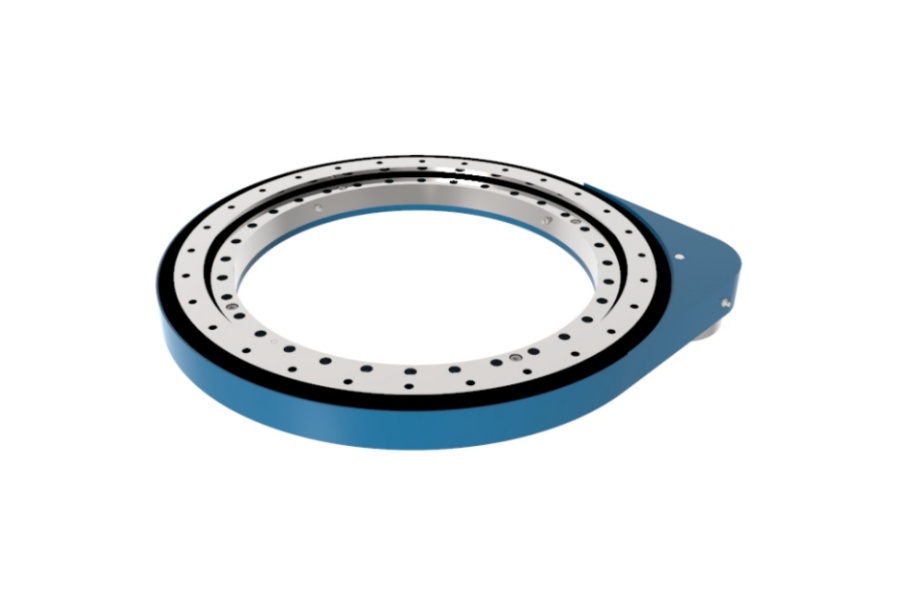

Lightweight Slewing Ring Gear Drive SP-I 0541 for Modern Automation

What is Lightweight Slewing Ring Gear Drive SP-I 0541

Lightweight Slewing Ring Gear Drive SP-I 0541 revolutionizes motion control by integrating hardened gears and a robust slewing ring into a single sealed unit. Unlike traditional systems, it combines helical or spur gears with a high-capacity rotary bearing, enabling smooth 360° rotation under extreme radial/axial loads. Its lightweight design (≈75 kg for comparable models) reduces structural strain while maintaining IP65-rated environmental protection, making it ideal for space-constrained, high-rpm industrial settings.

Similarities and Differences Between Worm Gear and Gear-Type Slewing Drives

Similarities:

Both convert rotational input into controlled output movement for pivoting or indexing.

Support combined axial/radial loads and transfer torque via gear meshing.

Used in solar trackers, cranes, and robotics where precise angular positioning is critical.

Differences:

Efficiency & Speed: Gear-type drives (like SP-I 0541) achieve >95% efficiency and higher rotational speeds (up to 20 rpm); worm drives typically operate at 50-70% efficiency due to sliding friction.

Backlash Control: Gear drives minimize backlash via preloaded bearings; worm drives inherently self-lock but sacrifice responsiveness.

Maintenance: Gear drives use sealed lubrication for extended service life; worm drives require frequent relubrication.

Load Dynamics: Gear drives handle abrupt load changes better; worm drives excel in static holding torque scenarios.

Key Features of Lightweight Slewing Ring Gear Drive SP-I 0541

High Torque Density: Delivers up to 6,550 N·m max torque and 4,680 N·m nominal torque in a compact footprint.

Dynamic Load Resilience: Axial static load capacity of 1,100 kN and radial static load of 410 kN ensure stability under shock loads.

Precision Gearing: 4mm module gears with 183-ring/15-pinion teeth configuration provide a 12.2:1 reduction ratio for smooth motion.

Integrated Sealing: Full-unit encapsulation prevents contaminant ingress (IP65), eliminating external seals and reducing maintenance.

Weight Optimization: Aluminum alloy housings cut mass by 30% vs. steel counterparts without compromising structural rigidity.

Applications of Lightweight Slewing Ring Gear Drive SP-I 0541

Robotic Automation: Enables high-speed articulation in assembly arms and welding robots.

Material Handling: Powers rotary conveyors and palletizers requiring <20 rpm precision indexing.

Renewable Energy: Drives solar tracker azimuth axes, leveraging high dynamic load ratings (255 kN axial/220 kN radial).

Heavy Machinery: Replaces traditional turntable bearings in excavator slewing rings and crane jibs.

Medical Imaging Equipment: Supports silent, vibration-free rotation in CT scanners and X-ray gantries.

Price Determinants for Lightweight Slewing Ring Gear Drive SP-I 0541

Material Selection: Aircraft-grade aluminum housings vs. cast steel impact cost by 15-25%.

Customization: Tailored gear ratios, mounting interfaces, or corrosion-resistant coatings add 10-30% to base pricing.

Volume Orders: Bulk procurement reduces unit costs by up to 20% through optimized manufacturing.

Certifications: ISO 9001/14001 compliance and load-test validation increase production overheads by 5-15%.

Supply Chain Factors: Global steel/alloy price fluctuations and logistics complexity directly affect final pricing.

Trusted Supplier of Lightweight Slewing Ring Gear Drive SP-I 0541

LYRADRIVE specializes in advanced motion solutions, with 12+ years of expertise in slewing drive innovation. Their SP-I series, including the 0541 variant, undergoes rigorous FEM analysis and dynamic testing to exceed ISO 6336 standards. Offering end-to-end support—from CAD integration to lifecycle maintenance—LYRADRIVE serves Fortune 500 industrial clients across 30+ countries, prioritizing rapid prototyping (<4 weeks) and 24/7 technical consultancy.