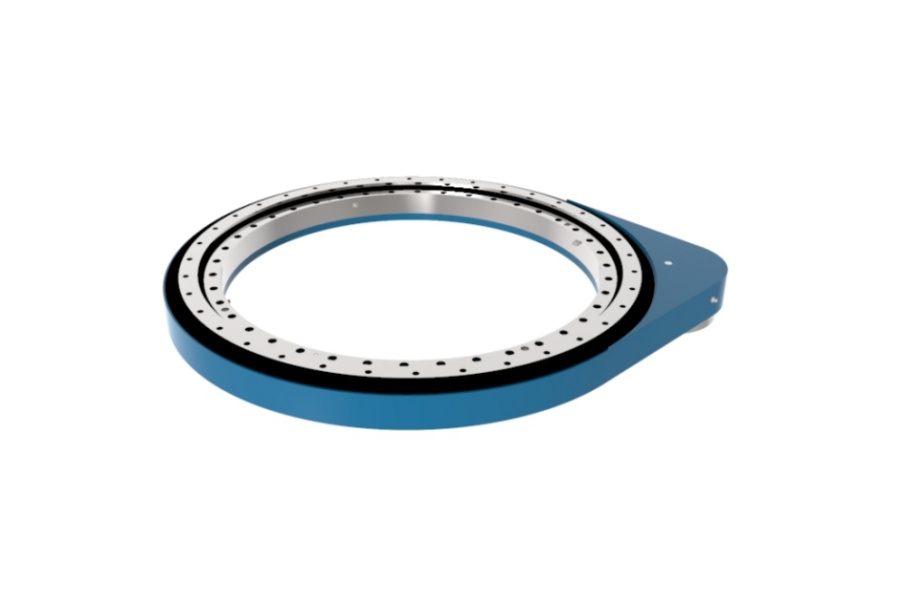

Lightweight Slewing Ring Gear Drive SP-I 0741

What is Lightweight Slewing Ring Gear Drive SP-I 0741

Lightweight Slewing Ring Gear Drive SP-I 0741 is a compact, high-efficiency rotary transmission system comprising precisely meshed spur or helical gears housed within a rigid base structure. Designed to replace traditional slewing bearings, it integrates hardened gears and a sealed rotary bearing into a single modular unit. This configuration achieves a gear ratio of 13.8:1 (15-pinion teeth to 207-ring teeth) with a 4mm module, supporting axial static loads up to 1,270 kN and radial static loads of 480 kN. With a maximum torque capacity of 7,450 N·m and a weight of just 85 kg, it enables smooth rotation at speeds up to 20 RPM while maintaining IP65-rated environmental protection.

Analysis of Factors Affecting Gear Slewing Drive Transmission Efficiency

Gear Tooth Geometry and Precision: Imperfect tooth profiles or deviations in manufacturing increase friction and energy losses. Precision grinding of SP-I 0741’s gears minimizes sliding friction.

Lubrication Quality: Inadequate or degraded lubricant causes metal-to-metal contact, generating heat. The SP-I 0741’s sealed design retains optimal grease consistency for long-term efficiency.

Alignment and Mounting: Misalignment between gears induces uneven load distribution and vibration. The unit’s rigid base ensures precise gear meshing and minimizes parasitic losses.

Surface Finish and Material: Rough surfaces increase wear. SP-I 0741 uses hardened steel gears with polished surfaces to reduce friction coefficients.

Load Magnitude and Direction: Excessive radial or axial loads beyond design limits deform components. SP-I 0741’s balanced load ratings (Cax: 270 kN, Crad: 230 kN) ensure efficiency under dynamic stress.

Bearing Friction: The integrated slewing ring’s low-friction design reduces torque resistance during rotation.

Key Features of Lightweight Slewing Ring Gear Drive SP-I 0741

High Load Capacity: Supports axial static loads of 1,270 kN and radial static loads of 480 kN.

Optimized Torque Handling: Delivers max torque of 7,450 N·m and holding torque of 7,450 N·m.

Precision Gearing: 4mm module gears with hardened teeth ensure minimal backlash and efficient power transfer.

Robust Sealing: IP65-rated seals protect internal components from dust, moisture, and contaminants.

Integrated Design: Combines gears, bearings, and housing into a pre-assembled unit, simplifying installation and reducing maintenance.

Weight Efficiency: At 85 kg, it offers a superior strength-to-weight ratio for mobile and compact machinery.

High-Speed Capability: Operates at up to 20 RPM for responsive motion control.

Applications of Lightweight Slewing Ring Gear Drive SP-I 0741

Solar Trackers: Enables precise panel positioning under high wind loads.

Construction Machinery: Used in crane jibs, excavator booms, and concrete pumpers for reliable 360° rotation.

Automated Material Handling: Powers rotary tables and palletizers in warehouse robotics.

Wind Turbine Yaw Systems: Provides durable rotation for nacelle alignment.

Heavy-Duty Transport: Integrates into mining conveyors and port cranes for swing motion under extreme loads.

Agricultural Equipment: Drives irrigation pivots and harvesting arms requiring corrosion resistance.

Defense Systems: Supports radar platforms and turret mechanisms demanding shock tolerance.

Factors Influencing Lightweight Slewing Ring Gear Drive SP-I 0741 Pricing

Material Costs: Fluctuations in alloy steel prices directly impact manufacturing expenses.

Customization Requirements: Modifications like special coatings, non-standard gear ratios, or unique mounting interfaces increase costs.

Order Volume: Bulk purchases typically reduce per-unit pricing due to economies of scale.

Quality Certifications: Compliance with ISO 9001 or industry-specific standards involves rigorous testing, adding to production overhead.

Geographic Logistics: Shipping tariffs, import duties, and supply chain complexity affect final pricing.

Technical Support Needs: Integrated control systems or extended warranties may elevate project costs.

Market Demand: High demand in sectors like renewable energy can influence pricing dynamics.

Supplier of Lightweight Slewing Ring Gear Drive SP-I 0741

LYRADRIVE specializes in engineered motion solutions, manufacturing high-performance slewing drives like the SP-I 0741 for global industrial markets. With expertise in gear systems and rotary bearings, LYRADRIVE emphasizes R&D-driven design, stringent quality control, and application-specific customization. Their integrated approach ensures reliable performance in sectors ranging from renewable energy to heavy machinery, backed by comprehensive technical support and responsive supply chain management.