Precision Lightweight Slewing Drives SP-I 0941 Gear Drive Analysis

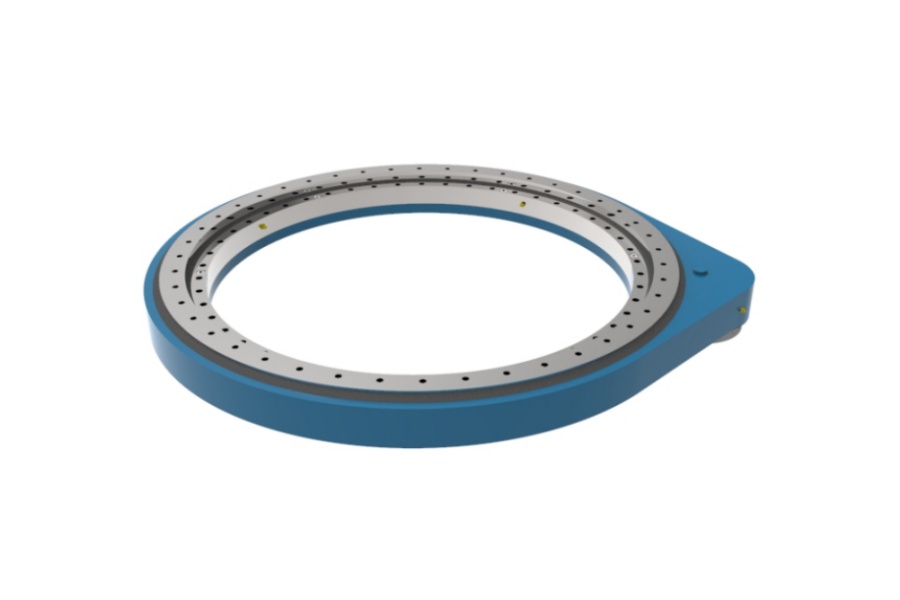

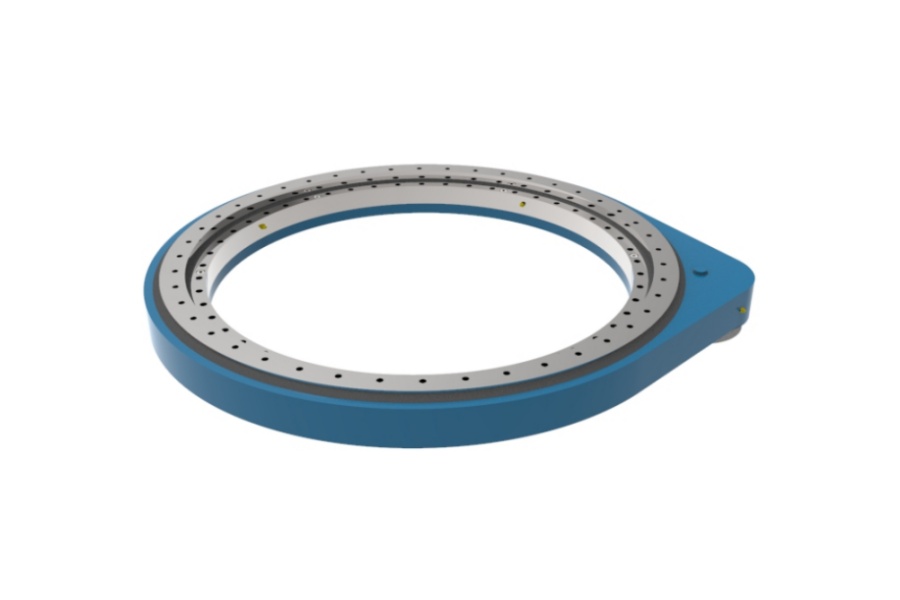

What is Lightweight Slewing Ring Gear Drive SP-I 0941

Lightweight Slewing Ring Gear Drive SP-I 0941 is a highly efficient, compact gear reduction transmission unit designed specifically for precise and reliable rotational movement within industrial automation systems. This integrated drive system replaces traditional, often cumbersome, slewing bearing and separate drive gear assemblies. At its core, it features a precision-engineered slewing ring bearing combined with a built-in spur gear reduction mechanism. The primary components include an outer ring gear (258 teeth) and a central pinion gear (15 teeth), achieving a significant 17.2:1 reduction ratio. Engineered for high rotational speeds up to 15 RPM, it delivers substantial torque – a maximum drive torque of 9250 N.m and a nominal torque of 6700 N.m – while maintaining an impressive static holding torque of 9250 N.m. Its design prioritizes both strength and weight savings, achieving a mass of just 106 kg despite offering substantial load capacities: 600 KN radial static load, 1610 KN axial static load, 250 KN radial dynamic load, and 295 KN axial dynamic load. This unit is a fully sealed, pre-assembled solution, significantly simplifying installation and enhancing reliability.

How to Select Couplings for Spur Gear Slewing Drives

Choosing the correct coupling for a spur gear slewing drive like the SP-I 0941 is critical for optimal performance, longevity, and backlash control. Several key factors must guide the selection process. First, consider the Torque Requirements. The coupling must reliably transmit the motor's output torque and handle peak loads without failure, referencing the drive's nominal (6700 N.m) and maximum (9250 N.m) torque specifications. Second, Misalignment Compensation is essential. While precise alignment is ideal, couplings must accommodate minor inevitable angular, parallel, and axial shaft misalignments between the motor/gearbox output and the slewing drive input shaft; flexible couplings like bellows, disc packs, or grid types are common choices. Third, Backlash Control is paramount for precision positioning inherent in slewing drives. Applications requiring high accuracy demand couplings with minimal or zero backlash to prevent lost motion and ensure responsive control; Oldham couplings or specific zero-backlash elastomeric types might be suitable depending on torque levels. Fourth, the Operational Environment dictates material and sealing needs. Factors like temperature extremes, dust, moisture (the SP-I 0941 is IP65 sealed, but the coupling might be exposed), and potential chemical exposure influence whether a stainless steel coupling or one with specific protective coatings is required. Finally, Stiffness and Torsional Response impact system dynamics. The coupling's torsional stiffness should match the application needs – high stiffness for precise positioning, while some controlled flexibility might be beneficial in shock-load scenarios to protect components. Always consult the slewing drive manufacturer's recommendations and coupling supplier data sheets to ensure compatibility with the drive's input shaft specifications and the operational demands of the system.

Key Features of Lightweight Slewing Ring Gear Drive SP-I 0941

The SP-I 0941 distinguishes itself through a combination of engineering excellence and practical design features tailored for industrial efficiency. Its Integrated Unitized Design is foundational, eliminating the complex alignment challenges associated with separate slewing bearings and pinion gears. The precision meshing between the hardened 258-tooth ring gear and 15-tooth pinion gear is factory-set and secured within the drive housing, permanently resolving critical backlash issues. This integration extends to Robust Load Handling, supported by high-grade materials and heat treatment, enabling exceptional static (1610 KN axial, 600 KN radial) and dynamic (295 KN axial, 250 KN radial) load capacities within a remarkably compact footprint. The drive's Lightweight Construction (106 kg) is a significant advantage, achieved through optimized structural design and material selection without compromising strength, facilitating easier handling, installation, and potentially reducing the structural requirements of the host machinery. Superior Sealing and Protection is ensured by a comprehensive IP65-rated sealing system. This full-seal design effectively excludes contaminants like dust and moisture while retaining lubricant, dramatically extending service intervals and component life, even in harsh environments. High-Speed Capability is another standout feature, with the drive supporting operational speeds up to 15 RPM, making it suitable for applications demanding faster cycle times beyond typical slewing ring capabilities. Finally, the Versatile Mounting and Drive Options offer flexibility; the unit provides standard mounting interfaces and can be efficiently driven by either electric motors or hydraulic motors, allowing seamless integration into diverse power systems.

Primary Applications of Lightweight Slewing Ring Gear Drive SP-I 0941

The SP-I 0941's blend of high torque, precision, speed, and compact design makes it indispensable across numerous sectors requiring reliable rotational motion. In Material Handling Equipment, it excels as the core component for robust industrial rotary tables, sophisticated indexing systems, and the slewing mechanisms of heavy-duty manipulators and robotic arms, handling substantial loads with precision. Construction Machinery heavily relies on its capabilities; it provides the essential slewing function for compact crane jibs, facilitates precise positioning in drilling equipment, and drives the rotation of trencher booms and specialized attachments, enduring demanding site conditions. Within Automated Machinery and Industrial Robotics, this drive enables the accurate rotary indexing of workstations, powers the pivotal joints of robotic arms requiring both strength and precision, and drives conveyor turntables and automated assembly platforms efficiently. The Transport and Logistics Sector utilizes it in heavy-duty turntables for vehicle positioning, automated guided vehicle (AGV) docking and rotation systems, and specialized cargo handling equipment. Furthermore, its IP65 rating makes it well-suited for Outdoor and Harsh Environment Applications, including sophisticated solar tracking systems that require precise sun following, agricultural machinery components, and various inspection or maintenance platforms exposed to the elements.

Factors Influencing Lightweight Slewing Ring Gear Drive SP-I 0941 Pricing

The price point of the SP-I 0941 slewing drive is determined by several interrelated factors reflecting its engineering, materials, and manufacturing complexity. Material Specifications and Quality form a primary cost driver. The use of high-alloy steels for gears and rings, specialized bearing steel for the slewing ring, advanced sealing materials, and comprehensive corrosion protection treatments significantly impact the base material cost. The Precision Manufacturing Processes involved are extensive and costly. Precision forging of ring blanks, multi-stage CNC gear machining (hobbing, shaping, grinding) to achieve the required tooth profile accuracy and surface finish, specialized heat treatment (carburizing, hardening, tempering) for critical components, and meticulous assembly with controlled preload and backlash demand sophisticated equipment and skilled labor. Scale of Production and Order Volume naturally affects unit cost. Larger production runs allow for better amortization of fixed costs like tooling and setup, while smaller custom batches inherently carry higher per-unit costs. Customization Requirements beyond the standard SP-I 0941 specification add expense. Modifications like special mounting flanges, unique input shaft configurations, alternative sealing solutions, or specific lubrication types require additional engineering and non-standard machining. Quality Assurance and Testing Protocols contribute to the cost structure. Rigorous in-process inspections, final performance testing (e.g., torque verification, backlash measurement, seal integrity checks), and comprehensive certification (ISO standards, material traceability) ensure reliability but add overhead. Finally, the Supply Chain and Market Dynamics, including raw material price fluctuations (steel alloys), energy costs, regional manufacturing expenses, and competitive market positioning, all influence the final pricing delivered to the customer.

Supplier of Lightweight Slewing Ring Gear Drive SP-I 0941

LYRADRIVE stands as a prominent designer and manufacturer of high-performance slewing drives and precision gear systems, including the advanced SP-I 0941 Lightweight Slewing Ring Gear Drive. The company leverages extensive engineering expertise focused on delivering robust, reliable, and efficient rotary motion solutions tailored for demanding industrial environments. LYRADRIVE's commitment to quality is evident in their rigorous manufacturing processes and adherence to international standards, ensuring components meet exacting specifications for load capacity, precision, and longevity. They offer significant value through deep application knowledge, providing technical support to optimize drive selection and integration for specific customer needs. Furthermore, LYRADRIVE demonstrates flexibility by offering customization options on core products like the SP-I series, allowing modifications to mounting interfaces, seals, lubrication, or shaft configurations to perfectly match unique application requirements. Their global supply chain capabilities ensure reliable delivery and support for customers worldwide. Choosing LYRADRIVE means partnering with a dedicated specialist committed to advancing rotary drive technology and providing solutions that enhance machine performance and reliability.