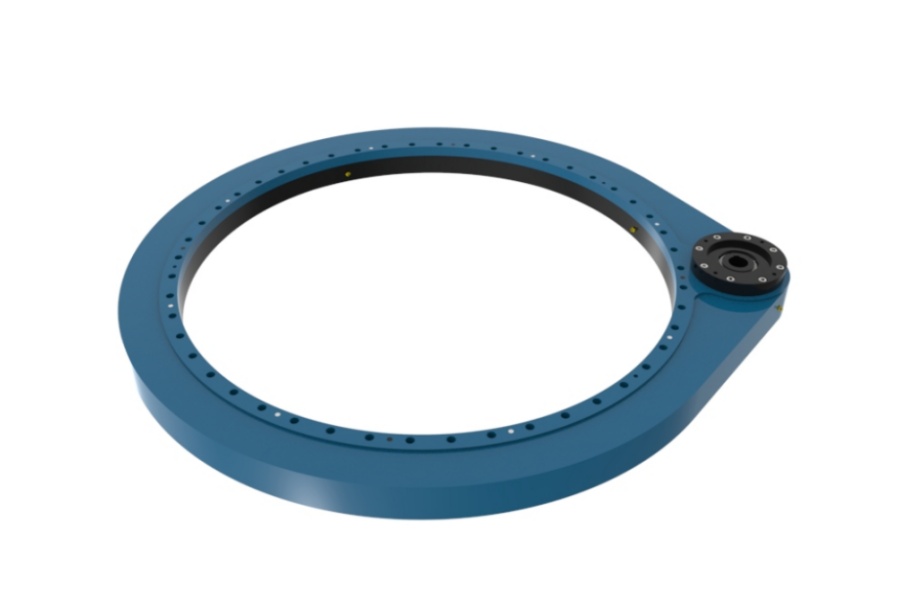

Lightweight Slewing Ring Gear Drive SP-I 1091 High Torque Compact Rotation

What is Lightweight Slewing Ring Gear Drive SP-I 1091

Lightweight Slewing Ring Gear Drive SP-I 1091 is an advanced external spur gear slewing drive engineered for applications demanding substantial torque output, high load handling, and moderate speeds within a constrained footprint and low weight profile. It integrates a robust slewing ring bearing with a precisely meshed spur gear system, featuring a 15-tooth pinion (Z1) driving a large 294-tooth external gear ring (Z2) mounted on the slewing ring's outer race, achieving a substantial 19.6:1 gear reduction. Designed to handle significant static and dynamic loads (Co ax = 1860 kN, Co rad = 700 kN, Cax = 310 kN, Crad = 265 kN) while weighing only 123 kg, it offers a maximum output torque of 10650 N.m and a nominal torque of 7700 N.m. The unit is fully enclosed in a sealed housing rated IP65, protecting internal components from dust and moisture ingress. This integrated, unitized design simplifies installation, drastically reduces maintenance needs, and provides a highly reliable solution for heavy-duty indexing and continuous rotation in automation, material handling, and industrial machinery requiring power in a compact form.

Coupling Selection for Spur Gear Slewing Drives

Selecting the appropriate coupling to connect the drive motor to the input shaft of a spur gear slewing drive like the SP-I 1091 is crucial for efficient power transmission, system longevity, and minimizing vibration and misalignment issues. Key considerations include:

Torque Capacity

The coupling must reliably transmit the motor's maximum torque, including peak loads encountered during start-up, stopping, reversing, or potential jamming. It must exceed the drive's maximum input torque requirement with a sufficient safety factor. Consider both continuous and peak torque ratings of the coupling.

Misalignment Compensation

Couplings must accommodate inevitable misalignment between the motor shaft and the slewing drive input shaft. Types include parallel offset, angular misalignment, and axial displacement. Different coupling types offer varying degrees of compensation: jaw couplings handle moderate angular/parallel, disc couplings handle higher torque with good angular/parallel, gear couplings handle high torque and significant misalignment, Oldham couplings handle parallel offset, and bellows couplings offer precise motion with angular/parallel. Rigid couplings require perfect alignment.

Backlash Requirements

Applications needing precise positioning or reversal control require couplings with minimal or zero backlash, like disc, bellows, or preloaded Oldham types. Applications tolerant of minor position lag can use jaw or grid couplings. SP-I 1091 applications often benefit from low-backlash couplings.

Torsional Stiffness

Torsional stiffness impacts system responsiveness and potential for resonance. High torsional stiffness couplings provide immediate response but can transmit more shock. Lower stiffness couplings dampen vibrations and shock loads but may cause slight lag. Match stiffness to the application's dynamic requirements.

Speed Capability

Ensure the coupling's maximum rotational speed rating exceeds the slewing drive's operational speed (up to 12 RPM for SP-I 1091) and potential overspeed scenarios.

Environmental Factors

Consider operating temperature, exposure to chemicals, dust, moisture, or washdowns. Coupling materials (metal, urethane, Hytrel) and designs must withstand the environment. IP65 drives like the SP-I 1091 benefit from couplings offering some inherent protection.

Ease of Installation and Maintenance

Space constraints around the drive input favor compact couplings. Consider accessibility for installation and future inspection or replacement. Maintenance-free couplings are preferred.

Common Coupling Types for SP-I 1091

Disc Couplings: Excellent choice for high torque (suitable for 10650 N.m), good misalignment compensation, zero backlash, high torsional stiffness, and compact size. Ideal for precision positioning.

Jaw Couplings (Spider Type): Cost-effective, good vibration damping (elastomer spider), moderate torque/misalignment capacity. Potential for slight backlash. Ensure elastomer rating suits environment.

Grid Couplings: Robust, handle high torque and shock loads, good misalignment capacity. Some backlash inherent. Larger and heavier than disc types.

Bellows Couplings: Zero backlash, high torsional rigidity, excellent for precise motion control. Lower torque capacity than disc types for equivalent size. Excellent for high precision.

Gear Couplings: Handle very high torque and significant misalignment. Require lubrication, can have backlash. Typically larger/heavier. Suitable for harsh environments.

Rigid Couplings: Only use when perfect, permanent alignment is guaranteed. Offer maximum torsional stiffness and zero backlash. Transmit all vibration and shock.

Key Features of Lightweight Slewing Ring Gear Drive SP-I 1091

The SP-I 1091 excels through a combination of power, efficiency, and intelligent design tailored for demanding yet space-conscious applications:

High Torque Density: Delivers impressive maximum torque (10650 N.m) and nominal torque (7700 N.m) within a compact footprint and low weight (123 kg), offering exceptional power-to-weight and power-to-size ratios.

Significant Load Capacity: Engineered to handle substantial forces with static axial load capacity of 1860 kN, static radial load of 700 kN, dynamic axial load of 310 kN, and dynamic radial load of 265 kN, enabling use in heavy-duty automation and material handling.

Efficient Spur Gear Transmission: The direct meshing spur gear design (M=4mm, Z1=15/Z2=294) provides a highly efficient 19.6:1 speed reduction with minimal energy loss compared to worm gear alternatives, lowering operational power requirements.

Integrated Unitized Design: Pre-assembled unit combining slewing ring bearing and gearing simplifies installation, eliminates complex alignment between components, reduces potential failure points, and ensures consistent performance.

IP65 Sealed Enclosure: The fully sealed housing provides robust protection against dust ingress and low-pressure water jets from any direction, ensuring reliable operation in harsh industrial environments and significantly extending service life.

Moderate Speed Operation: Optimized for controlled motion with a maximum operational speed of 12 RPM, suitable for precise indexing and heavy-duty rotational applications where slower, more powerful movement is required.

Low Maintenance Design: Sealed construction and high-quality internal lubrication are designed for long service intervals with minimal maintenance, reducing downtime and total cost of ownership.

High Gear Ratio (19.6:1): Provides substantial speed reduction and torque multiplication in a single stage, simplifying overall drive train design.

Flexible Drive Input: Accommodates various drive sources, including electric motors and hydraulic motors, offering versatility for integration into different power systems.

Robust Construction: Utilizes high-strength materials and precision manufacturing to ensure durability and long-term reliability under demanding operating conditions.

Diverse Applications of Lightweight Slewing Ring Gear Drive SP-I 1091

The SP-I 1091's blend of high torque, significant load capacity, compactness, and sealed reliability makes it ideal for numerous industrial sectors:

Heavy Industrial Automation: Powers the rotation of large robotic arms for welding or material handling, heavy-duty indexing tables for machining centers or assembly stations, automated welding positioners for large structures, and palletizing/depalletizing systems handling substantial loads.

Material Handling & Logistics: Drives rotating platforms for heavy-duty automated guided vehicles (AGVs) and autonomous mobile robots (AMRs), powers turntables in large conveyor sorting systems, operates slewing sections in automated storage and retrieval systems (AS/RS) for bulky items, and controls rotation in industrial bagging or filling stations.

Packaging Machinery (Heavy Duty): Provides robust rotation for large filling carousels, heavy container handling turntables, and capping stations within industrial packaging lines, benefiting from its torque and sealed design.

Construction Equipment (Compact/Midsize): Powers rotation functions in compact telehandlers, small to mid-sized aerial work platforms (AWPs), material positioning arms on small excavators, and specialized attachments requiring significant torque in a compact space.

Renewable Energy - Solar Tracking (Single Axis - Medium/Large Arrays): Suitable for driving the azimuth rotation of medium to large single-axis solar tracker systems where torque capacity and reliability are critical, and weight is still a consideration.

Industrial Mixing & Agitation: Drives the rotation of mixers or agitators for industrial processes handling viscous materials or large batches where torque and sealed reliability are essential.

Stage & Entertainment Machinery: Powers robust rotating platforms for heavy stage sets, large exhibits, or dynamic structures requiring reliable and powerful motion control.

Test & Simulation Equipment: Used in heavy-duty test rigs requiring precise angular positioning or continuous rotation under load, such as component fatigue testing or environmental simulation turntables.

Defense & Aerospace (Ground Support/Auxiliary): Powers rotation in radar or sensor positioning mounts, camera gimbals for larger systems, hatch mechanisms, or specialized ground support equipment where torque and compactness are valued.

Factors Influencing Lightweight Slewing Ring Gear Drive SP-I 1091 Pricing

The cost of the SP-I 1091 is determined by factors related to its engineering, materials, manufacturing complexity, and market dynamics:

Base Model Specifications: The standard SP-I 1091 configuration, with its defined high torque ratings (Md max=10650 N.m, Md nom=7700 N.m), significant load capacities (Co ax=1860 kN, Co rad=700 kN, etc.), gear ratio (19.6:1), weight (123 kg), IP65 sealing, and integrated unit design, forms the core pricing foundation.

Material Costs: The use of high-quality, high-strength alloy steels for the gears (requiring precise carburizing, hardening, and tempering) and the slewing ring components (races, balls), along with durable sealing materials (nitrile, Viton) capable of withstanding the environment and loads, significantly impacts the raw material cost base.

Precision Manufacturing & Finishing: Achieving the required gear tooth profile accuracy (involute), surface finish (often necessitating grinding or honing post-heat treatment), precise bearing raceway geometry, controlled gear backlash, and overall dimensional tolerances demands advanced CNC machining, skilled labor, and rigorous quality control measures, contributing substantially to production costs.

Complex Heat Treatment: The carburizing process for deep case hardening the gears, followed by precise hardening and tempering, is energy-intensive and requires sophisticated furnace technology and strict process control to achieve the necessary hardness depth, surface hardness (typically 58-62 HRC), and core toughness without introducing excessive distortion, adding significant cost.

Integrated Unitized Construction: The pre-assembled, pre-lubricated, and sealed unit design, while offering major installation and reliability benefits, involves additional manufacturing steps (seal installation, lubrication filling, final testing under load) compared to supplying separate components.

Level of Customization: While often sold as a standard unit, customizations impact price:

Special Mounting Interfaces: Custom flange designs, bolt hole patterns, pilot diameters, or tapped holes on the fixed or rotating rings.

Enhanced Sealing: Upgraded seal materials (e.g., Viton for high temp/chemical resistance) or designs (additional wipers, labyrinth seals) beyond standard IP65.

Special Lubrication: Specific high-performance grease formulations for extreme temperatures (-40°C to +120°C+), extended life, or food-grade requirements.

Integrated Sensors: Adding rotary encoders, resolvers, or temperature sensors for position/speed feedback or condition monitoring.

Surface Protection: Special anti-corrosion coatings (e.g., zinc-nickel plating, epoxy paints) for highly corrosive environments.

Modified Input Shaft: Keyway type/size, splined shaft, or custom flange for direct motor mounting.

Order Volume & Production Run: Economies of scale significantly affect unit cost. Larger orders allow for optimized production scheduling and material purchasing, reducing the cost per unit.

Supply Chain & Logistics: Fluctuations in raw material costs (steel, alloys), energy prices, transportation costs (shipping, freight), import/export duties, and labor rates can influence the final price.

Supplier of Lightweight Slewing Ring Gear Drive SP-I 1091

LYRADRIVE is a globally recognized manufacturer specializing in the design and production of high-performance slewing drives, slewing bearings, and precision gearing systems, including the innovative Lightweight Slewing Ring Gear Drive SP-I series exemplified by the SP-I 1091. Focused on delivering robust, reliable, and efficient rotational motion solutions, LYRADRIVE serves diverse industries such as industrial automation, heavy material handling, construction, renewable energy, and specialized machinery. They leverage advanced engineering capabilities, state-of-the-art manufacturing facilities, and stringent quality control protocols to produce drives like the SP-I 1091, known for their integrated design, significant torque density, and environmental resilience (IP65). LYRADRIVE emphasizes providing solutions that simplify integration, minimize maintenance requirements, and ensure long operational life, enabling customers to enhance the performance and reliability of their equipment.