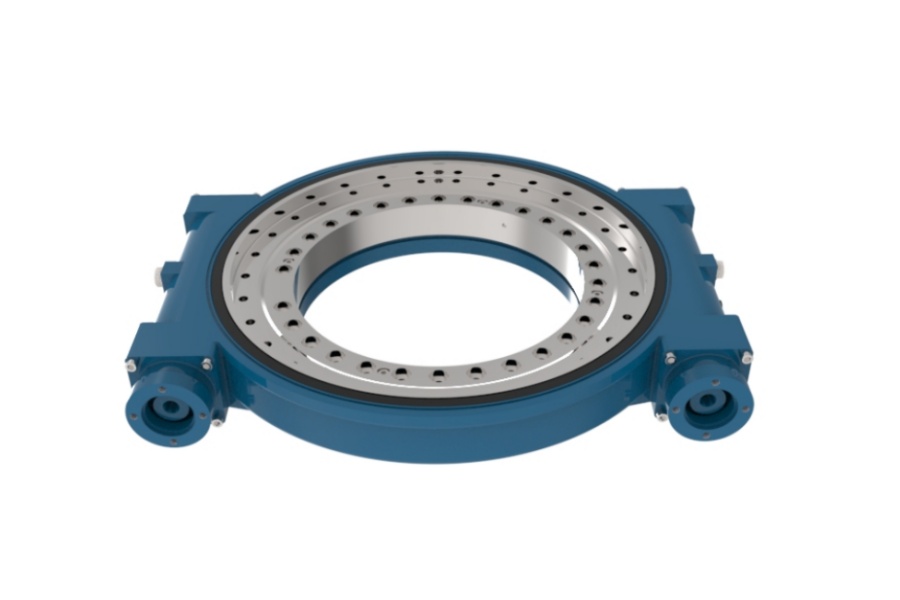

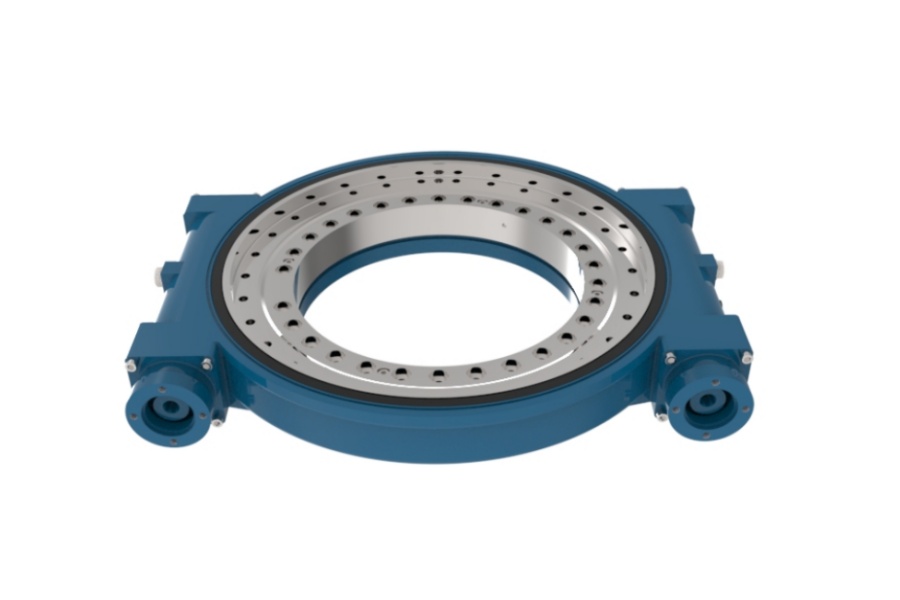

Double Worm Slewing Drive WED25 The Heavy-Duty Rotation Solution

What is Double Worm Slewing Drive WED25

Double Worm Slewing Drive WED25 represents a pinnacle of heavy-duty rotational drive technology, characterized by its dual worm gear configuration driving a central worm wheel integrated with a robust slewing bearing. This sophisticated system is meticulously engineered to transmit substantial rotational force while managing extreme static and dynamic loads – axial, radial, and tilting moments – with exceptional control. The WED25 integrates a large-diameter slewing ring featuring a double-row ball bearing design with a compact, integrated gearbox housing two opposing worm gears. This arrangement significantly enhances load distribution, torque capacity, and operational safety compared to single-worm drives. Built for relentless performance in harsh environments like construction sites, mines, offshore platforms, and wind farms, the WED25 delivers unparalleled reliability, precision, and longevity where failure is not an option. Its compact yet immensely powerful form factor facilitates integration into space-constrained, high-performance machinery requiring robust rotation.

Classification of Toroidal Worm Gears in Slewing Drives

The worm gear is the critical heart of torque transmission in slewing drives like the WED25. Toroidal (or hourglass) worm gears are particularly valued for their superior load-carrying capacity, efficiency, and smoother operation compared to cylindrical worms. Within slewing drives, toroidal worm gears can be classified based on their geometry and manufacturing methods:

ZA Profile (Straight Axial): Features a straight profile in the axial section. While simpler to manufacture, it offers slightly lower contact area and load capacity compared to more complex profiles.

ZN Profile (Straight Normal): Characterized by a straight profile in the normal section. This profile provides a good balance between manufacturability and performance, offering improved contact over ZA.

ZK Profile (Convolute - Milled): Generated using a conical milling cutter. ZK worms provide a significantly larger contact area and higher load capacity than ZA or ZN types, leading to enhanced efficiency and durability. They are a common choice for demanding applications.

ZI Profile (Involute Helicoid - Ground): Generated using a grinding wheel, resulting in a precise involute helicoid profile. ZI worms offer the highest possible load capacity, efficiency, smoothness, and precision due to optimal tooth contact geometry and hardened, ground surfaces. They are typically used in premium, high-performance slewing drives like the WED25. The grinding process allows for tighter tolerances and superior surface finish.

ZC Profile (Concave - Hobbed): Features a concave profile generated by hobbing. While offering good performance, it is less common than ZK or ZI in high-end slewing drives.

The WED25 typically employs high-precision ZI or ZK profile toroidal worm gears, often hardened and ground, to maximize torque transmission efficiency, minimize wear, ensure smooth operation under heavy load, and achieve the drive's rated performance and long service life. The dual-worm configuration further leverages the advantages of these high-quality gear profiles.

Key Features of Double Worm Slewing Drive WED25

The WED25 distinguishes itself through an array of advanced engineering features meticulously designed for peak performance under the most extreme conditions:

Exceptional Torque Capacity: Delivering a commanding 57.3 kN.m output torque, coupled with an outstanding 268.7 kN.m holding torque, the WED25 provides the immense force required to initiate and maintain rotation of colossal loads under high resistance or stalling conditions. Its tilting moment capacity of 310 kN.m provides critical stability against overturning forces generated by off-center loads.

Superior Load Handling: Engineered for extreme duty, the WED25 boasts remarkable static load ratings of 2360 kN axially and 945 kN radially. Its dynamic load capacities are equally robust at 590 kN axial and 470 kN radial, enabling it to reliably support and rotate extremely heavy components while enduring significant operational forces, shock loads, and inertia, setting it apart for the heaviest applications.

Double-Row Ball Bearing Design: This configuration, featuring an optimized eight-point contact pattern, dramatically increases the drive's ability to handle combined axial, radial, and moment loads simultaneously. It enhances structural rigidity, reduces deformation under load, and significantly contributes to the drive's overall stability and longevity.

Inherent Safety with Self-Locking: The dual worm gear design provides a crucial safety feature: self-locking. When input power ceases, the drive inherently resists back-driving, preventing unintended and potentially hazardous rotation of the load. This is essential for safety in critical applications like cranes, lifts, and positioning systems, ensuring stability even during power loss or braking system disengagement.

Enhanced Efficiency and Durability: The dual worm configuration distributes the driving load more evenly across the worm wheel compared to a single worm drive. This load sharing reduces stress concentrations on individual gear teeth, minimizes wear, improves overall transmission efficiency, and significantly enhances the system's operational lifespan and reliability under continuous heavy use.

Robust Sealed Enclosure: The entire drive assembly is protected within a high-integrity, sealed housing. This vital feature shields the precision gears and bearings from environmental contaminants like abrasive dust, dirt, moisture, corrosive agents (e.g., salt spray), and high-pressure washdown, dramatically extending service life and reducing maintenance requirements.

High Precision Tracking: Achieving a tracking precision of ≤0.1°, the WED25 ensures exceptional positional accuracy and repeatability. This level of control is paramount for applications demanding precise angular alignment or smooth, controlled rotational motion, such as radar tracking, antenna pointing, automated assembly, or solar tracking.

Heavy-Duty Construction & Materials: With a substantial weight of 231 kg, the WED25 embodies its robust design using high-strength alloy steels, precision-machined components, and specialized bearing materials. This construction ensures structural integrity, resistance to fatigue and deformation under load, and long-term reliability in rigorous industrial, marine, and mobile equipment applications.

Optimized Gear Ratio: The standard 104:1 gear ratio provides an excellent balance between rotational speed and torque multiplication, making it highly suitable for a wide range of applications requiring controlled, powerful movement without excessive speed. This ratio can often be customized.

Diverse Applications of Double Worm Slewing Drive WED25

The unparalleled combination of immense torque, extreme load capacity, precision, and rugged reliability makes the WED25 indispensable across numerous demanding industrial sectors:

Heavy Lifting & Crane Systems: This drive is the core power behind slewing functions in the largest cranes: mobile cranes (all-terrain, crawler), tower cranes for skyscraper construction, massive gantry cranes in shipyards, and heavy-lift offshore cranes. It enables smooth, controlled rotation of booms and superstructures while lifting and moving multi-ton loads. Its self-locking and tilting moment capacity are critical here.

Mining & Quarrying Equipment: Essential for rotating the superstructures of large hydraulic mining shovels and excavators, positioning stackers and reclaimers handling bulk materials, and powering the rotation of bucket-wheel excavators and drilling rigs in the harshest mining environments. The WED25's dust resistance and immense load capacity are vital.

Shipbuilding, Ports & Offshore: Powers deck cranes on cargo ships, tugboats, and offshore support vessels (OSVs). Drives winches, capstans, and heavy-duty davits/A-frames. Essential for equipment positioning on offshore oil & gas platforms, Floating Production Storage and Offloading (FPSO) vessels, and wind turbine installation vessels (WTIVs). Its corrosion resistance (enhanced by sealing and optional coatings) is paramount.

Renewable Energy - Wind Turbines: A core component of the yaw drive system within large wind turbine nacelles. It precisely rotates the entire nacelle to continuously align the rotor optimally with the wind direction, maximizing energy capture. The self-locking capability is crucial for holding position securely during storms or maintenance.

Renewable Energy - Solar Tracking: Powers the azimuth rotation of large central inverter platforms or concentrated solar power (CSP) heliostat fields, ensuring precise sun tracking throughout the day for maximum energy yield. Durability and precision are key.

Heavy Industrial Machinery: Found in large turntables for forging presses or heavy component handling, rotary kilns and dryers in process industries, mixer drums for concrete or industrial materials, and positioning systems for heavy automated welding or machining stations.

Material Handling & Logistics: Drives heavy-duty rotating platforms in warehouses or ports, automated storage and retrieval system (AS/RS) turntables handling large loads, and positioning systems for automated guided vehicles (AGVs) carrying substantial payloads.

Aerospace, Defense & Specialized Equipment: Used in radar antenna positioning systems (ground-based, naval), satellite communication (SATCOM) antenna tracking, missile launcher turntables, and specialized ground support equipment requiring high torque and pinpoint accuracy under demanding conditions.

Factors Influencing Double Worm Slewing Drive WED25 Pricing

The cost of a Double Worm Slewing Drive WED25 is determined by several key variables reflecting its complexity, performance, and customization:

Base Model Specifications: The standard WED25 configuration, with its defined torque (57.3 kN.m), exceptional load ratings (Axial Static: 2360 kN, Radial Static: 945 kN, Tilting Moment: 310 kN.m, etc.), gear ratio (104:1), and standard features (double-row ball bearing, standard sealing), establishes the fundamental price point.

Material Selection & Quality: The grade and quality of materials significantly impact cost. High-strength, hardened, and ground alloy steels for worms and wheel, specialized high-grade bearing steel for races, premium seals (e.g., Viton), and high-performance lubricants contribute to durability and performance but increase material costs substantially.

Manufacturing Complexity & Precision: Achieving the tight tolerances required for smooth operation, efficient load distribution, and ≤0.1° precision involves sophisticated processes: precision grinding/honing of gears, specialized heat treatment (carburizing, induction hardening), meticulous bearing pre-load setting, and rigorous quality control (including load testing). The dual-worm design inherently adds complexity and cost over single-worm drives.

Double-Row Ball Bearing: The inclusion of this high-capacity bearing configuration is a significant contributor to the cost but is essential for the drive's rated performance.

Level of Customization: Modifications from the standard design are major cost drivers:

Increased Performance: Higher torque output, increased static/dynamic load ratings, or higher tilting moment capacity beyond standard.

Alternative Gear Ratios: Custom ratios (e.g., 120:1 for more torque, 80:1 for higher speed) requiring different gear sets.

Enhanced Sealing: Specialized seals (labyrinth, multi-lip, spring-energized), special grease, or pressurized air purge systems for extreme environments (submersion, high dust, corrosive chemicals, high-pressure washdown).

Special Bearings: Custom bearing configurations, preloads, materials (e.g., stainless steel), or clearance specifications.

Mounting & Interface Customization: Unique flange designs, bolt patterns, pilot diameters, or integrated mounting structures.

Surface Treatments & Coatings: Corrosion-resistant plating (e.g., zinc-nickel), specialized paints, or other surface protections for harsh environments.

Integrated Sensors: Encoders, resolvers, temperature sensors, or vibration sensors for condition monitoring.

Special Lubrication: Specific grease types or centralized lubrication system interfaces.

Order Volume: Economies of scale apply. Larger production runs typically reduce the unit cost compared to single-unit or small-batch orders.

Supply Chain Dynamics: Fluctuations in the cost of raw materials (steel, specialty alloys), energy, logistics (shipping, tariffs), and labor can influence pricing.

Supplier Engineering & Support: Comprehensive engineering support for integration, rigorous testing protocols (performance, life, environmental), detailed documentation, warranty terms, and after-sales service contribute to the overall value and cost structure.

Supplier of Double Worm Slewing Drive WED25

LYRADRIVE is a leading global manufacturer specializing in the design and production of high-performance slewing drives, slewing bearings, and precision gearing solutions, including the advanced WED25 series. Renowned for engineering robustness and reliability, LYRADRIVE focuses on delivering heavy-duty rotation solutions tailored for the extreme demands of industries like construction, mining, renewable energy, marine, and specialized automation. Their core strength lies in significant engineering customization capabilities, allowing modifications to the WED25's torque, load ratings, gear ratio, sealing, bearings, and mounting configurations to perfectly match specific application challenges. LYRADRIVE combines advanced manufacturing with stringent quality control and comprehensive technical support throughout the product lifecycle. The WED25 exemplifies their commitment to providing durable, high-capacity slewing drives built for critical performance and longevity in the world's toughest operational environments.