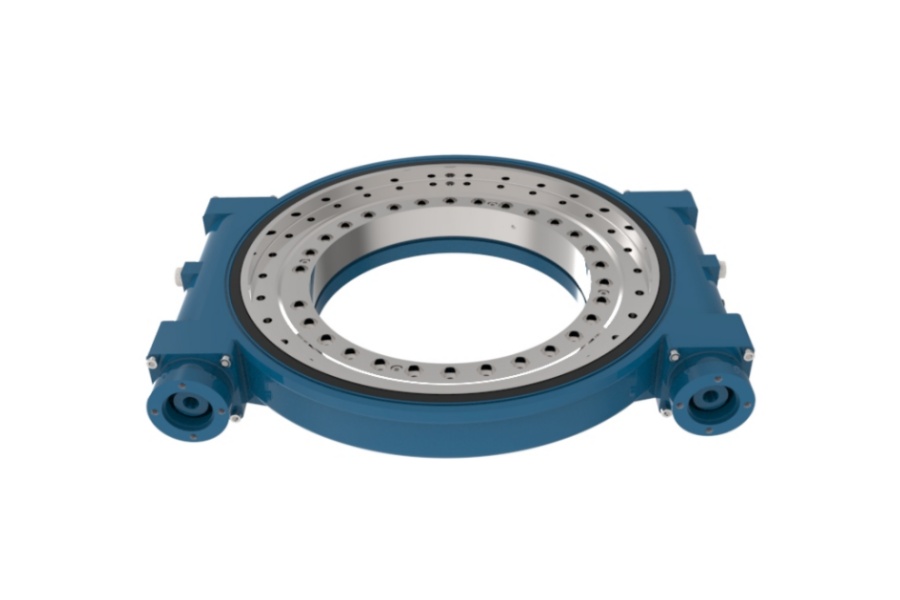

Double Worm Slewing Drive WED21 Powering Heavy-Duty Rotation

What is Double Worm Slewing Drive WED21

Double Worm Slewing Drive WED21 represents a significant advancement in slewing drive technology, characterized by its dual worm gear configuration. This heavy-duty component integrates a large-diameter slewing bearing with a compact, integrated gearbox featuring two opposing worm gears driving a single worm wheel attached to the bearing's outer ring. This sophisticated design is purpose-built to transmit substantial torque, manage immense static and dynamic loads (axial, radial, and tilting moments), and provide highly controlled rotational motion. The WED21 is engineered to deliver unparalleled performance in applications where reliability under heavy stress and precise movement are non-negotiable. Its compact yet powerful form factor makes it ideal for integration into space-constrained, high-performance machinery.

Introduction to Slewing Drive Shaft Connection Methods

The method of connecting the input drive shaft to a slewing drive like the WED21 is crucial for efficient power transmission, minimizing backlash, and ensuring operational longevity. Several common connection types are employed, each suited to specific requirements:

Solid Input Shaft: A direct, robust connection where the motor shaft (or a coupled extension) inserts directly into the drive unit's input bore, secured with locking elements like set screws or keyways. This offers simplicity and high torque capacity but requires precise shaft alignment.

Shaft Adapters: Flanged adapters mounted onto the motor shaft provide a standardized interface (e.g., pilot diameter, bolt pattern) for connecting to the slewing drive's input flange. This simplifies motor interchangeability and accommodates minor misalignments.

Input Flanges: The slewing drive features a machined flange with a pilot and bolt holes. The motor is then bolted directly to this flange, ensuring a rigid connection. This is common for high-torque applications and promotes compactness.

Splined Connections: Involves mating splines on the motor shaft and the slewing drive input. This provides very high torque transmission capability and positive engagement but requires precise machining and alignment.

Keyed Connections: Utilizes a keyway and key to transmit torque between the motor shaft and the slewing drive input bore. A common and cost-effective solution for moderate torque applications.

Taper Lock Bushings: A popular and versatile method where a tapered bushing is fitted onto the motor shaft and compressed within the slewing drive's input bore using screws. This creates a secure, backlash-free connection that is relatively easy to install and remove, accommodating slight shaft size variations.

The optimal connection method for the WED21 depends on the driven motor type, available space, required torque transmission, ease of maintenance, and alignment precision achievable. LYRADRIVE typically offers the WED21 with input flanges or provisions for solid shaft/Taper Lock connections as standard, ensuring flexibility for integration.

Key Features of Double Worm Slewing Drive WED21

The WED21 distinguishes itself through a combination of advanced engineering features designed for peak performance and durability in the most challenging environments:

Exceptional Torque Capacity: Delivering a powerful 48 kN.m output torque, coupled with an impressive 179.8 kN.m holding torque, the WED21 provides the muscle needed to initiate and maintain rotation of massive loads, even under high resistance or stalling conditions. Its tilting moment capacity of 203 kN.m further underscores its stability under off-center or overturning loads.

Superior Load Handling: Engineered for extreme duty, the WED21 boasts remarkable static load ratings of 1598 kN axially and 640 kN radially. Its dynamic load capacities are equally robust at 385 kN axial and 335 kN radial, enabling it to reliably support and rotate heavy components while enduring significant operational forces and inertia. This sets it apart from lighter-duty slewing drives.

Inherent Safety with Self-Locking: The dual worm gear design provides a critical safety feature: self-locking. When input power ceases, the drive inherently resists back-driving, preventing unintended rotation of the load. This is essential for safety in applications like cranes, lifts, and positioning systems, ensuring stability even during power loss or braking system disengagement.

Enhanced Efficiency and Durability: The dual worm configuration distributes the driving load more evenly across the worm wheel compared to a single worm drive. This load sharing reduces stress concentrations on individual gear teeth, minimizes wear, improves overall transmission efficiency, and significantly enhances the system's operational lifespan and reliability under continuous heavy use.

Robust Sealed Housing: The drive assembly is encased within a high-integrity sealed housing. This crucial protection shields the precision gears and bearings from environmental contaminants like dust, dirt, moisture, and corrosive agents (e.g., salt spray in marine settings), significantly extending service life and reducing maintenance needs.

High Precision Tracking: Achieving a tracking precision of ≤0.1°, the WED21 ensures exceptional positional accuracy. This level of control is vital for applications demanding precise angular alignment or smooth, controlled rotational motion, such as radar tracking, antenna pointing, or automated assembly processes.

Heavy-Duty Construction: With a substantial weight of 195 kg, the WED21 embodies its robust design and use of high-strength materials. This construction ensures structural integrity, resistance to deformation under load, and long-term reliability in rigorous industrial, marine, and mobile equipment applications.

Optimized Gear Ratio: The standard 90:1 gear ratio provides an excellent balance between rotational speed and torque multiplication, making it suitable for a wide range of applications requiring controlled, powerful movement without excessive speed.

Diverse Applications of Double Worm Slewing Drive WED21

The unique blend of high torque, immense load capacity, precision, and ruggedness makes the WED21 indispensable across numerous demanding sectors:

Heavy Machinery & Construction Equipment: This drive is the powerhouse behind critical functions in large-scale machinery. It enables the smooth slewing of crane booms (mobile, tower, crawler), provides precise rotation for excavator superstructures, controls the positioning of heavy-duty drilling rigs, and facilitates the movement of large mining equipment like stackers, reclaimers, and bucket-wheel excavators. Its ability to handle high static and dynamic loads is paramount here.

Renewable Energy - Wind Turbines: Within wind turbine nacelles, the WED21 serves as a core component of the yaw drive system. It enables the precise rotation of the entire nacelle to continuously align the rotor optimally with the wind direction, maximizing energy capture. The self-locking capability is crucial for holding position during high winds or maintenance, preventing uncontrolled yawing.

Marine & Offshore Applications: Thriving in harsh marine environments, the WED21 powers deck cranes on ships and offshore support vessels (OSVs), handling cargo and equipment. It drives winches and capstans, positions equipment on offshore platforms (oil & gas rigs, wind turbine installation vessels), and operates heavy-duty davits and A-frames. Its sealed construction is vital for corrosion resistance.

Aerospace & Defense: Precision and reliability are paramount. The WED21 is employed in sophisticated systems such as radar antenna positioning (ground-based, naval, airborne), satellite communication (SATCOM) antenna tracking systems, missile launcher turntables, and ground support equipment requiring high torque and accurate angular control.

Industrial Automation & Robotics: In demanding automation settings, the WED21 provides the robust rotational motion needed for large robotic arms used in material handling or welding, heavy-duty indexing tables, automated guided vehicle (AGV) turntables carrying substantial loads, and large-scale assembly line positioning systems requiring both strength and precision.

Material Handling: Large turntables in warehouses or ports, rotating platforms for presses or heavy machinery, and automated storage and retrieval systems (AS/RS) rely on the WED21 to smoothly and safely rotate significant loads, optimizing space and workflow efficiency.

Oil & Gas: Beyond offshore platforms, the WED21 finds use in onshore applications like rotating heavy valves or actuators in processing plants, positioning equipment on drilling rigs, and powering specialized machinery used in pipeline construction and maintenance.

Factors Influencing Double Worm Slewing Drive WED21 Pricing

The cost of a Double Worm Slewing Drive WED21 is not a fixed figure but is determined by several key variables reflecting the complexity and customization involved:

Base Model Specifications: The standard WED21 configuration, with its defined torque (48 kN.m), load ratings (Axial Static: 1598 kN, Radial Static: 640 kN, etc.), gear ratio (90:1), and standard features, establishes a baseline price.

Material Selection: The grade and quality of materials used significantly impact cost. High-strength alloy steels for gears, hardened and ground components, specialized bearing steel races, and high-performance seals contribute to durability and performance but also increase material costs compared to lower-grade alternatives.

Manufacturing Complexity & Precision: Achieving the high tolerances required for smooth operation, load distribution, and ≤0.1° precision involves sophisticated machining processes (grinding, honing), precise heat treatment, and stringent quality control, all contributing to manufacturing costs. The dual worm design itself adds complexity over single-worm drives.

Level of Customization: Modifications from the standard design represent a major cost driver. Customizations include:

Increased torque or load ratings beyond standard.

Alternative gear ratios (e.g., 120:1 for more torque, 60:1 for higher speed).

Enhanced sealing solutions (special lip seals, labyrinth seals) for extreme environments (submersion, high-pressure washdown, corrosive atmospheres).

Special bearing configurations (different types, preloads, or materials) optimized for specific load combinations.

Custom mounting interfaces (flange designs, bolt patterns, pilot diameters).

Special surface treatments or coatings (e.g., corrosion-resistant plating like zinc-nickel, specialized paints).

Integration of sensors (encoders, resolvers, temperature sensors).

Order Quantity: Economies of scale apply. Larger production runs typically reduce the unit cost compared to single-unit or small-batch orders due to optimized setup times, material purchasing, and manufacturing flow.

Supply Chain Dynamics: Fluctuations in the cost of raw materials (steel, specialty alloys), energy prices, and logistics (shipping, tariffs) can influence the final price.

Supplier Value-Added Services: Engineering support for integration, extensive testing protocols (load, life, environmental), comprehensive documentation, warranty terms, and after-sales support contribute to the overall value proposition and cost structure.

Supplier of Double Worm Slewing Drive WED21

LYRADRIVE stands as a prominent manufacturer specializing in high-performance slewing drives, bearings, and precision gearing solutions. They are recognized for engineering robust components like the WED21 series, designed specifically to meet the rigorous demands of heavy industry, renewable energy, marine, and specialized automation. LYRADRIVE emphasizes engineering excellence, offering significant customization capabilities to tailor drives to exact application requirements, including modifications to torque, gear ratio, sealing, bearings, and mounting configurations. Their commitment extends beyond manufacturing to providing comprehensive technical support throughout the product lifecycle. The WED21 exemplifies LYRADRIVE's focus on delivering reliable, high-capacity rotational drive systems built for longevity and demanding operational environments.