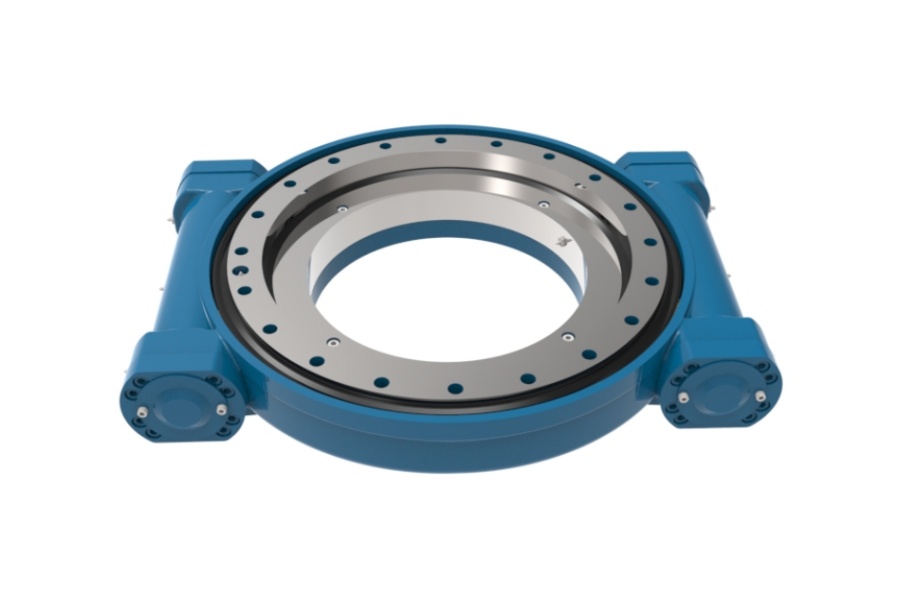

Double Worm Slewing Drive WED17 Power and Precision

What is Double Worm Slewing Drive WED17

Double Worm Slewing Drive WED17 is an advanced mechanical drive unit engineered to provide robust and reliable rotational movement for heavy machinery. Its defining feature is the use of two opposing worm gears simultaneously driving a central worm wheel. This unique dual-worm configuration dramatically increases both the output torque (9.45 kN.m) and holding torque (108.5 kN.m) compared to traditional single-worm drives. Designed for compactness while maintaining high performance, the WED17 integrates precision gearing and high-capacity slewing bearings within a sealed housing, enabling it to efficiently handle combined axial, radial, and tilting moment loads (142.4 kN.m). Its design ensures compatibility with installations originally intended for the WE17 series, facilitating upgrades. The drive offers inherent self-locking safety, high tracking precision (≤0.1°), and a substantial gear ratio (104:1), making it indispensable where power, safety, space efficiency, and control are paramount.

Analyzing Worm and Wheel Meshing Lifespan in Slewing Drives

The longevity of a slewing drive like the WED17 hinges critically on the durability of the worm gear meshing interface. This lifespan is influenced by several interconnected factors:

Lubrication Regime: Consistent, high-quality lubrication is non-negotiable. It minimizes friction, dissipates heat generated at the sliding contact point, and prevents wear particles from accelerating abrasion. The sealed design of the WED17 helps retain lubricant and exclude contaminants, directly extending meshing life.

Material Selection and Hardening: Worms are typically manufactured from hardened alloy steel (e.g., case-hardened 17CrNiMo6, induction-hardened 42CrMo4). Worm wheels often use wear-resistant bronze alloys (e.g., CuSn12Ni2-C). Precise heat treatment processes (case hardening, tempering) ensure surface hardness on the worm (often 58-62 HRC) and a compatible, softer wheel material to optimize wear characteristics and minimize galling.

Gear Tooth Geometry and Precision Manufacturing: Conical (hourglass) worm profiles, commonly used in high-performance drives like the WED17, offer superior load distribution and multiple tooth contact points compared to cylindrical worms. This reduces localized stress and contact pressure. Achieving high manufacturing precision (profile accuracy, surface finish) minimizes initial wear-in and ensures optimal contact patterns.

Load Magnitude and Dynamics: Operating consistently near or exceeding rated loads, especially under shock or vibration, drastically accelerates wear. The WED17's dual-worm design inherently distributes load more evenly across the wheel teeth, reducing peak stress per tooth and enhancing overall meshing lifespan compared to single-worm equivalents under similar conditions.

Misalignment and Mounting Rigidity: Excessive misalignment due to flexible mounts or structural deflection concentrates loads unevenly on the gear teeth, leading to premature wear and potential failure. Ensuring a rigid mounting structure, as specified for the WED17, is crucial for achieving predicted lifespan.

Environmental Conditions: Exposure to abrasive dust, corrosive chemicals, or extreme temperatures can degrade lubricants and attack gear surfaces. The WED17's IP65-rated sealing provides significant protection against these elements. Regular maintenance, including lubricant analysis and replacement based on operating conditions and hours, is essential for maximizing meshing life. Predicting lifespan involves complex calculations considering these factors, but premium drives like the WED17, utilizing optimized materials, precision manufacturing, and robust sealing, are engineered for exceptionally long service intervals in harsh industrial environments.

Key Features of the Double Worm Slewing Drive WED17

The WED17 distinguishes itself through a combination of innovative design and robust engineering tailored for extreme performance:

Dual Worm Gear Mechanism: The core innovation driving its exceptional performance. Two opposing worms engage the central wheel, doubling the effective contact area and distributing load uniformly. This delivers:

Exceptional Output Torque: 9.45 kN.m for powerful rotational force.

Outstanding Holding Torque: 108.5 kN.m ensures secure load retention even when power is removed, critical for safety.

Superior Tilting Moment Resistance: Withstands 142.4 kN.m, providing unmatched stability under significant off-center or overturning loads.

Enhanced Rigidity & Reduced Wear: Load sharing minimizes stress concentration on individual gear teeth, reducing wear rates and maintaining low backlash over extended periods.

Inherent Backlash Control: The opposing action of the worms naturally compensates for minor clearances, promoting smoother motion and higher positioning accuracy.

Remarkable Load Capacity: Engineered to withstand extreme forces:

Static Loads: Axial: 1166 kN, Radial: 435 kN.

High-Capacity Bearings: Incorporates double-row eight-point contact ball bearings optimized for handling high combined loads efficiently.

High Precision Operation: Delivers exceptional tracking precision ≤ 0.1°, essential for applications demanding accurate angular positioning and repeatability.

Compact & Robust Design: Achieves its high power density within a space-efficient form factor, compatible with WE17 series mounting, simplifying integration into space-constrained applications without sacrificing strength.

Inherent Self-Locking Safety: The worm gear geometry provides a natural self-locking feature when input power ceases, preventing unintended load rotation and enhancing operational safety, particularly for suspended loads or critical positioning.

Effective Sealing (IP65): Provides robust protection against dust ingress and low-pressure water jets from any direction, ensuring reliable performance in demanding environments like construction sites, mines, ports, and offshore locations.

Drive Source Flexibility: Compatible with various prime movers, including hydraulic motors and electric motors (geared or direct), offering versatility for diverse power systems and control schemes.

High Gear Ratio (104:1): Delivers significant speed reduction and substantial torque multiplication from the input source, enabling precise control of heavy loads.

Applications of the Double Worm Slewing Drive WED17

The WED17's unique blend of high torque, precision, compactness, and robustness makes it the drive solution of choice across numerous demanding sectors:

Heavy Construction & Mining: Excavator superstructure rotation, drilling rig turntables, heavy-duty material handling arms (grapples, shears), conveyor swing sections, mining shovel positioning systems, compact crane slewing.

Lifting & Handling Technology: Shipboard and mobile harbor crane slewing, industrial gantry crane rotation, offshore pedestal crane azimuth drives, heavy-duty lifting rotators for pipes/beams, container handling equipment.

Marine & Offshore Applications: Deck crane slewing, winch positioning systems, A-frame slew drives, sonar array rotation mechanisms, offshore access equipment turntables, davit rotation.

Renewable Energy: High-load azimuth drives for large-scale solar trackers (especially in high-wind regions), yaw drive mechanisms for medium-sized wind turbines (subject to load verification), positioning for concentrated solar power (CSP) mirrors.

Defense & Aerospace: Radar and satellite communication (SATCOM) antenna positioning systems, missile launcher turntables, heavy weapon station traverse and elevation drives, surveillance platform rotation.

Agriculture: Drive units for large center pivot irrigation systems, swing drives for heavy-duty grain conveyors and augers, positioning for large sprayer booms.

Industrial Automation & Manufacturing: Heavy-duty indexing tables, robotic welding positioner drives, large material handling turntables, furnace door rotation mechanisms, precision testing equipment positioning.

Factors Influencing Double Worm Slewing Drive WED17 Pricing

The investment in a WED17 unit is determined by several critical factors reflecting its advanced engineering and performance:

Material Quality & Specifications: The grade of alloy steel used for worms, wheel, housing, and bearing rings significantly impacts cost. Premium alloys offering enhanced strength, wear resistance (e.g., specific case-hardening grades), or superior corrosion protection (e.g., stainless components for marine use) command higher prices. The bronze alloy grade for the worm wheel is also a key cost factor.

Manufacturing Precision & Complexity: Achieving the specified ≤0.1° precision and optimal gear tooth profiles (especially for conical worms) requires advanced CNC machining, grinding, and potentially lapping processes. The dual-worm design inherently adds complexity compared to single-worm drives. Rigorous quality control and inspection protocols throughout manufacturing add cost but are essential for reliability.

Bearing Specification & Integration: The type, size, quality, and internal design (raceway hardening, roller precision) of the integrated double-row eight-point contact ball bearing are major cost drivers. Custom bearing preload or sealing requirements further influence price.

Heat Treatment & Surface Finishing: Critical processes like case hardening, induction hardening, tempering, and precision grinding of worm gears are essential for achieving the required hardness, wear resistance, and surface finish. These specialized treatments contribute substantially to the manufacturing cost.

Sealing System (IP65): The design and quality of seals (lip seals, labyrinth elements) and sealing materials capable of reliably achieving IP65 protection in harsh environments add to the component and assembly cost.

Customization & Modifications: While a standard WED17 exists, common customizations significantly affect price:

Special input shaft configurations (splined, keyed, tapered).

Custom mounting flange patterns or dimensions.

Specific lubrication port locations or types (grease nipples, oil plugs).

Special surface coatings (corrosion protection like zinc-nickel, paints).

Unique sealing requirements (higher IP rating, different seal materials).

Modified gear ratios (though 104:1 is standard).

Order Volume & Production Scale: Economies of scale apply. Larger production runs typically reduce the unit cost compared to small batch or single-unit orders.

Market Dynamics: Fluctuations in global raw material costs (steel, copper, alloying elements), energy prices, and overall manufacturing demand can cause price variations over time.

Supplier Value Proposition: Reputable manufacturers like LYRADRIVE, known for engineering expertise, stringent quality standards, reliability, comprehensive testing, technical support, and warranty, may command a premium reflecting the lower total cost of ownership and reduced risk they provide.

Reliable Supplier of Double Worm Slewing Drive WED17

For high-performance Double Worm Slewing Drives like the WED17, LYRADRIVE is a recognized manufacturer specializing in precision-engineered drive solutions. They focus on the design and production of robust slewing drives built to meet the rigorous demands of heavy industry, lifting, renewable energy, and specialized automation applications globally. LYRADRIVE utilizes advanced manufacturing techniques and stringent quality control processes to ensure their products, including the WED17 series, deliver exceptional load capacity, durability, and precise motion control. Choosing LYRADRIVE provides access to reliable drive technology backed by engineering expertise.