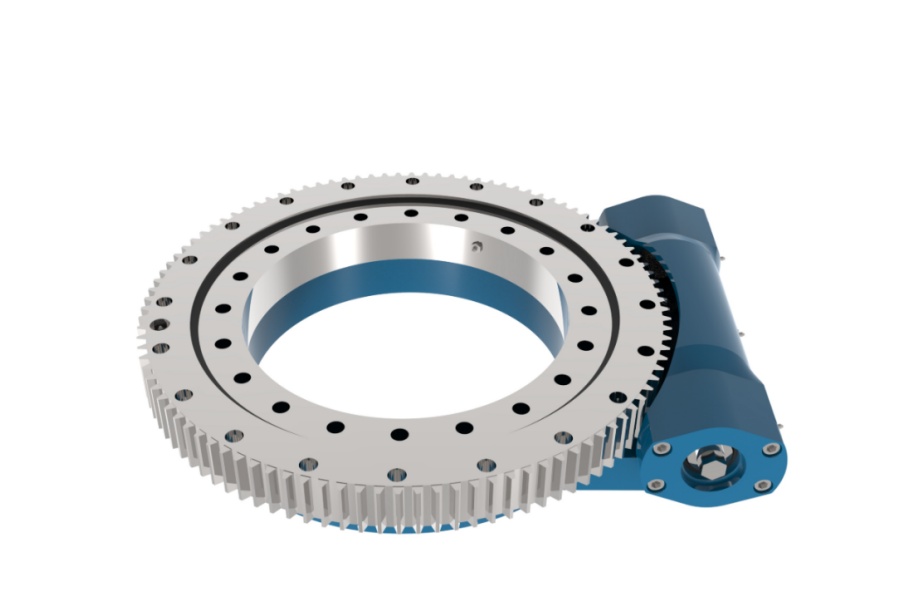

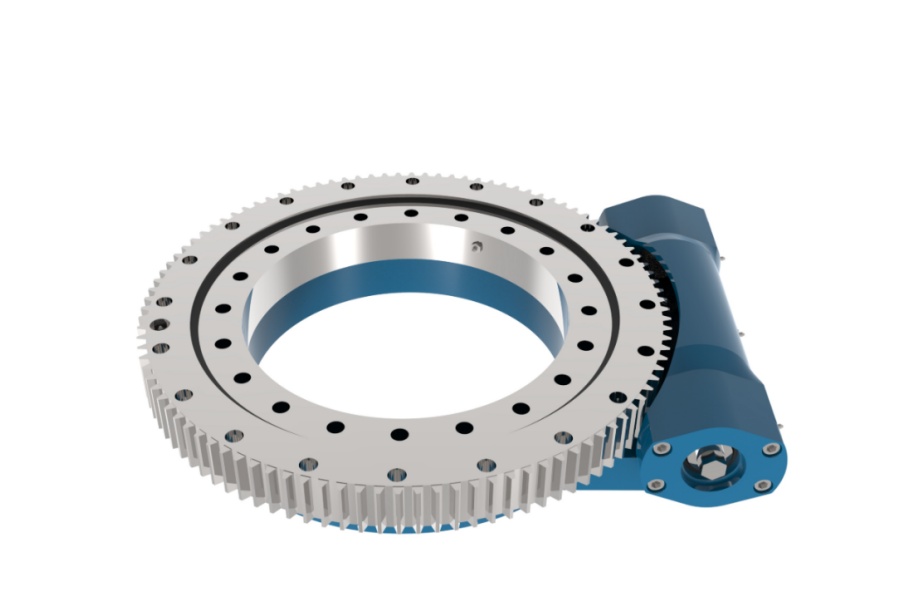

Open Housing Slew Drive S19 Technical Guide

What is Open Housing Slew Drive S19

Open Housing Slew Drive S19 is an integrated modular drive assembly comprising three core components: a high-strength base, precision-ground worm shaft, and hardened worm wheel. Designed to simultaneously withstand axial, radial, and tilting moment loads, its open-frame architecture eliminates unnecessary housing mass while optimizing heat dissipation and maintenance access. This configuration achieves an exceptional 19 kN·m output torque and 1,480 kN static axial load capacity. The intrinsic self-locking mechanism prevents reverse rotation during power loss, making it ideal for safety-critical lifting and positioning operations where uncontrolled movement poses significant hazards.

Maintenance of Slew Drives in Construction Machinery

Proper maintenance is critical for reliability in abrasive construction environments. Follow these protocols:

Lubrication Management

Use ISO VG 320 synthetic grease with EP additives

Relubricate every 500 operating hours or after water immersion

Purge old grease until clean material emerges from seals

Wear Inspection

Monthly backlash measurement (tolerance <0.15°)

Check worm wheel teeth for pitting/spalling quarterly

Monitor bearing play with dial indicator

Contamination Control

Apply silicone sealant to mounting surfaces

Install protective bellows on exposed worm shafts

Pressure-wash only with seals protected

Load Monitoring

Avoid exceeding 80% of dynamic radial rating (320 kN)

Use torque sensors to prevent overload damage

Alignment Verification

Laser-align mounting surfaces annually

Shim base to ≤0.1mm/m flatness deviation

Features of Open Housing Slew Drive S19

Fail-Safe Self-Locking

The helical worm geometry creates mechanical locking under static conditions, providing 80.5 kN·m holding torque without auxiliary brakes. Critical for crane boom safety during power failures.

Multi-Tooth Load Distribution

Ring-enveloping worm design engages 4-5 gear teeth simultaneously, boosting torque transmission efficiency by 35% versus standard designs while reducing tooth stress.

Optimized Weight-to-Strength Ratio

Open housing reduces mass to 105 kg (22% lighter than enclosed equivalents) without compromising the 176 kN·m tilting moment resistance. Enhances mobile equipment payload capacity.

Precision Ground Components

Hardened alloy steel worm (HRC 58-62) and phosphor bronze gear achieve ≤0.15° tracking accuracy with controlled backlash for repeatable positioning.

Corrosion-Resistant Construction

Zinc-nickel plating with chromate conversion coating provides >1,000 hours salt spray resistance for marine and mining applications.

Thermal Management Design

Open structure enables 30% faster heat dissipation than enclosed drives, maintaining lubricant integrity during continuous 24/7 operation.

Applications of Open Housing Slew Drive S19

Tower Cranes: Handles extreme axial loads (1,480 kN static) during slewing while self-locking prevents boom drift in high winds.

Mining Shovels: Withstands 780 kN dynamic axial impacts during digging cycles. Open design simplifies grease purging in high-contamination environments.

Offshore Cranes: Corrosion-resistant build ensures reliability in saltwater spray. 320 kN dynamic radial capacity accommodates vessel motion.

Solar Trackers: Precision tracking (≤0.15°) optimizes energy harvest. 116:1 gear ratio enables precise positioning with standard actuators.

Piling Rigs: Resists 176 kN·m tilting moments during drilling operations. Multi-tooth engagement prevents tooth fracture under shock loads.

Aerial Platforms: Fail-safe locking secures baskets at height. Lightweight design maximizes working height capacity.

Shipboard Cranes: Integrated taper roller bearings handle combined wave-induced radial and axial forces.

Heavy-Duty Turntables: Supports 610 kN static radial loads for rotating industrial assemblies up to 150 tonnes.

Factors Influencing Open Housing Slew Drive S19 Pricing

Material Specifications

Premium alloy steels (42CrMo4) vs. standard grades: +18-25%

Marine-grade corrosion protection: +12%

Phosphor bronze vs. aluminum bronze gears: +15%

Custom Engineering

Non-standard mounting patterns: +8%

Hollow shaft modifications: +22%

Integrated absolute encoders: +30%

ATEX explosion-proofing: +40%

Certification Requirements

CE certification: +5%

DNV-GL marine approval: +18%

FEM 1.001 compliance: +7%

Order Parameters

Single-unit cost: Baseline

10-50 units: 15% discount

50+ units: 28% discount

Geographic Factors

EU/US production vs. Asia: +20%

Tariffs (Section 301): +25%

Expedited ocean freight: +18%

Service Packages

3-year extended warranty: +9%

On-site installation support: +15%

Predictive maintenance sensors: +12%

Supplier of Open Housing Slew Drive S19

LYRADRIVE manufactures the Open Housing Slew Drive S19 under ISO 9001:2015 certified processes, utilizing robotic machining cells and 3D metrology for micron-level precision.