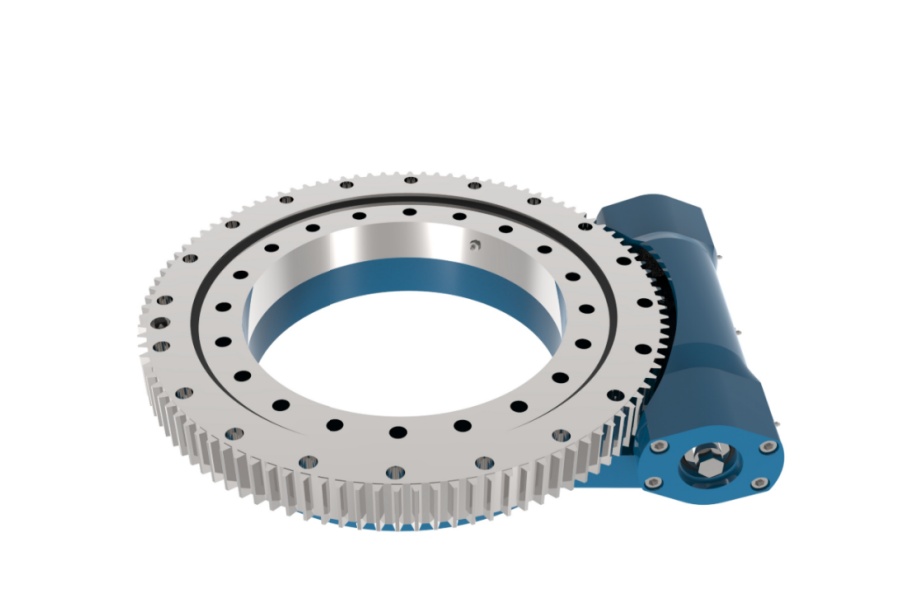

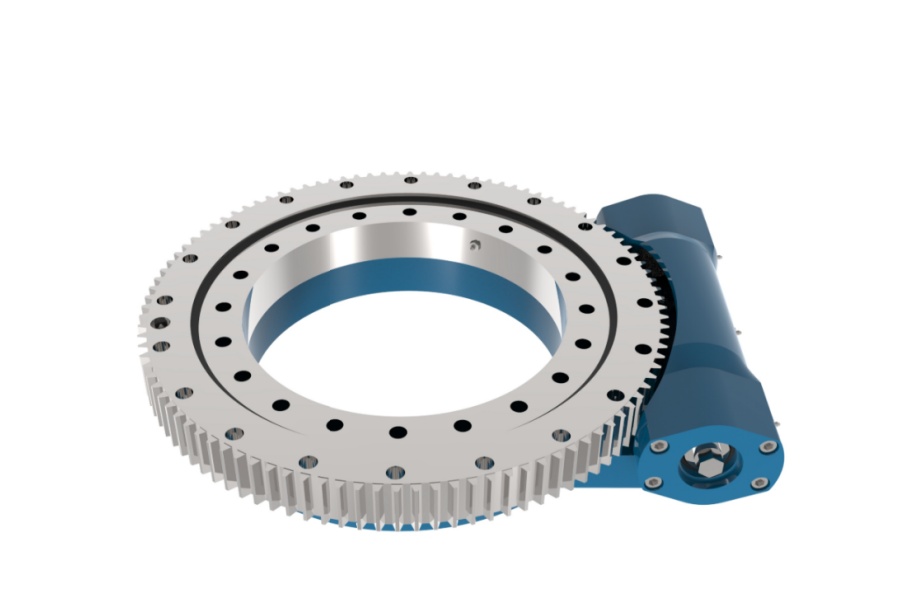

Open Housing Slew Drive S17 Technical Specifications and Applications

What is Open Housing Slew Drive S17

Open Housing Slew Drive S17 is an integrated modular drive unit comprising three core components: a rigid base, a precision-ground worm shaft, and a hardened worm wheel. Engineered to simultaneously manage axial loads, radial forces, and tilting moments, this open-frame design eliminates unnecessary housing mass while enhancing heat dissipation and maintenance access. Its fundamental purpose is to deliver controlled rotational motion in heavy machinery, featuring an intrinsic self-locking mechanism that prevents reverse rotation during power loss, critical for safety-sensitive operations.

Why Do Slew Drives Generate Noise During Operation?

Slew drive noise typically originates from four primary sources:

Gear Meshing Imperfections: Inaccurate tooth profiles, improper backlash adjustment, or misalignment between worm and gear teeth cause rhythmic clicking or grinding. Precision grinding (like S17's ring-enveloping design) minimizes this.

Bearing Wear/Damage: Pitted races or damaged rolling elements in support bearings create rumbling or grinding noises under load. High-grade tapered roller bearings in the S17 resist this degradation.

Inadequate Lubrication: Insufficient or degraded lubricant increases metal-to-metal friction, resulting in high-pitched whining or screeching. S17's open design facilitates easier lubrication checks and replenishment.

Structural Resonance: Vibrations from imbalanced loads or mounting surface flex can amplify gear or bearing noise. The S17's rigid base and optimized weight distribution dampen resonances.

Regular maintenance, precise installation, and using drives engineered for low-vibration operation (like the S17) significantly mitigate noise issues.

Features of Open Housing Slew Drive S17

Fail-Safe Self-Locking Mechanism: The unique helical geometry of the hardened steel worm shaft and phosphor bronze worm wheel creates a mechanical lock under static conditions. This prevents unintended reverse movement of the load if power is lost, a critical safety feature for lifting or positioning applications.

Enhanced Torque Capacity: Utilizes a ring-enveloping worm design that engages 4-5 teeth on the worm wheel simultaneously. This multi-tooth contact distributes load stress, enabling a high output torque of 10 kN·m and an exceptional holding torque of 72.3 kN·m for secure load retention.

Lightweight Open Structure: The absence of a full enclosure significantly reduces overall weight (88 kg) compared to equivalent enclosed drives. This weight saving is vital for mobile equipment (cranes, platforms) improving payload capacity and energy efficiency. The open design also simplifies visual inspection and lubrication.

Superior Load Handling: Engineered to withstand extreme forces: static axial loads up to 970 kN, static radial loads up to 390 kN, dynamic axial loads of 235 kN, dynamic radial loads of 205 kN, and a substantial tilting moment torque of 135.6 kN·m. Integrated tapered roller bearings efficiently distribute combined loads.

High Precision & Durability: Achieves tracking precision ≤0.15° for accurate positioning. Manufactured from premium alloy steels and wear-resistant bronze, hardened and ground for longevity. Designed for reliable performance in harsh environments with minimal maintenance requirements.

Optimized Thermal Management: The open housing allows superior heat dissipation compared to enclosed units, reducing thermal stress on components and lubricant during extended operation cycles.

Applications of Open Housing Slew Drive S17

Mobile Cranes: Provides robust and reliable slewing motion for crane superstructures. Its high tilting moment torque (135.6 kN·m) and holding torque (72.3 kN·m) ensure stability during lifting operations, while the lightweight design maximizes lifting capacity.

Aerial Work Platforms (AWPs): Enables precise rotation and positioning of booms and platforms. The self-locking feature is paramount for operator safety at height, preventing uncontrolled movement if hydraulic pressure or power fails.

Solar Tracking Systems: Drives azimuth and elevation axes in large-scale photovoltaic installations. High precision (≤0.15°) ensures optimal sun alignment, maximizing energy capture. The high load capacity handles wind forces.

Wind Turbine Yaw Drives: Powers the nacelle rotation for wind alignment. The immense holding torque prevents unwanted movement during gusty conditions, and the durability ensures long service life in exposed locations.

Industrial Automation & Robotics: Provides heavy-duty, precise rotation for robotic arms, welding positioners, turntables, and material handling equipment in manufacturing. Smooth operation and low backlash are crucial.

Material Handling Equipment: Drives rotary feeders, stacker-reclaimers, and large conveyor turntables requiring high torque and reliability under continuous operation.

Construction & Mining Machinery: Used in excavator attachments, drill rigs, and heavy equipment requiring robust rotational power and resistance to shock loads and contamination.

Stage & Entertainment Technology: Powers the smooth, precise, and reliable rotation of heavy stage elements, lighting rigs, and large screens.

Factors Affecting Open Housing Slew Drive S17 Pricing

Material Costs: Fluctuations in the price of high-grade alloy steels, phosphor bronze for the gear, specialized bearings, and protective coatings (e.g., phosphate) directly impact the base cost.

Customization Level: Standard S17 units offer baseline pricing. Customizations like specific mounting patterns (PCD, bolt holes), special shaft configurations (keyed, splined, hollow), integrated encoders or brakes, unique gear ratios, modified seals for extreme temperatures or IP ratings, or special surface treatments significantly increase cost.

Order Volume & Production Scale: Bulk purchases (typically 10+ units) benefit from economies of scale in manufacturing and procurement, lowering the per-unit price compared to single-unit orders. Continuous production runs are more cost-efficient than one-off builds.

Certifications & Compliance: Meeting stringent industry-specific certifications (e.g., CE, DNV-GL for marine, API for oil & gas, specific safety standards for cranes or lifts) involves additional testing, documentation, and quality control processes, adding to the cost.

Geopolitical & Supply Chain Factors: Tariffs, import/export duties, raw material availability, shipping costs, and regional labor rates can cause price variations. Global supply chain disruptions also impact lead times and cost.

Technical Support & Services: Inclusion of extended warranties, on-site installation supervision, comprehensive maintenance packages, or dedicated engineering support contributes to the total cost of ownership beyond the initial unit price.

Drive Configuration Complexity: While the core design is standardized, variations requiring complex machining, special heat treatment, or unique assembly procedures add cost.

Supplier of Open Housing Slew Drive S17

LYRADRIVE is a leading manufacturer specializing in high-performance motion control solutions, including the engineered and precision-built Open Housing Slew Drive S17. Operating under stringent ISO 9001 quality management systems, LYRADRIVE utilizes advanced CNC machining, grinding, and heat treatment processes to ensure each S17 unit meets exacting specifications for load capacity, precision, and durability. Their in-house engineering team provides comprehensive technical support for selection, integration, and customization, backed by rigorous testing protocols like Finite Element Analysis (FEA) and accelerated life testing. Committed to innovation and reliability, LYRADRIVE serves global OEMs and end-users across diverse sectors like material handling, renewable energy, construction, and industrial automation, offering scalable production and responsive service to meet demanding application requirements.