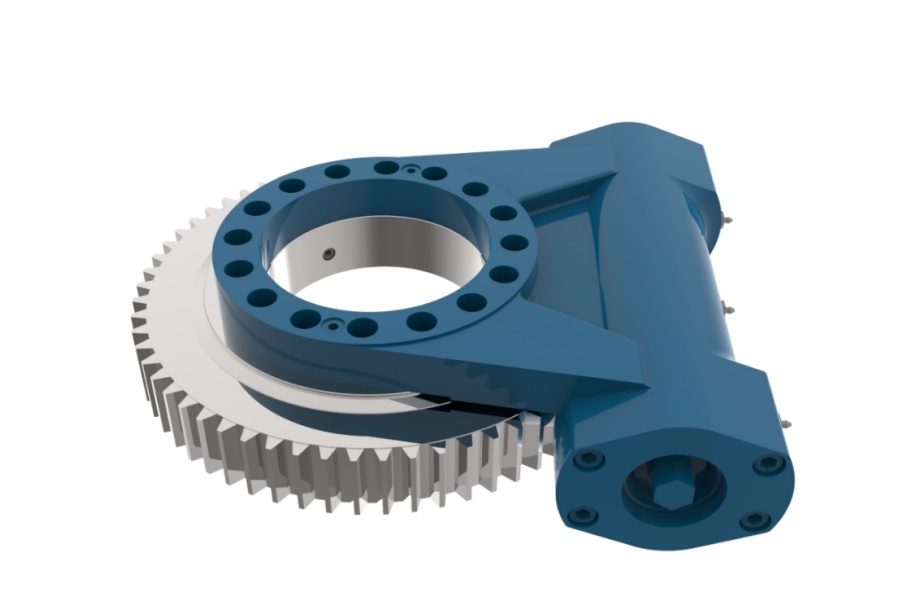

Open Housing Slewing Drive S9 Specifications and Applications

What is Open Housing Slewing Drive S9?

Open Housing Slewing Drive S9 is a versatile mechanical transmission solution combining a slewing ring bearing, a worm gear reduction, and mounting components into a compact assembly. Characterized by its open structural housing design, the S9 provides excellent access to internal components like the worm gear mesh, facilitating easier inspection, lubrication, and maintenance compared to fully enclosed drives. It integrates a hardened worm shaft and a precision worm wheel to deliver smooth, controlled rotational motion. A key feature is its enveloping worm design, allowing the worm to engage with 4-5 teeth on the wheel simultaneously, significantly boosting output torque (6.5 kN.m), holding torque (38.7 kN.m), and tilting moment capacity (33.9 kN.m) for its size. Engineered to handle substantial combined loads – static axial rating of 338 kN, static radial rating of 135 kN, dynamic axial rating of 81 kN, and dynamic radial rating of 71 kN – the S9 offers dependable performance. Its inherent self-locking mechanism prevents back-driving when power is removed, enhancing operational safety. The open housing design contributes to a reduced weight (39 kg), making it ideal for weight-sensitive applications. While offering good inherent protection, its open nature might necessitate additional environmental guarding depending on the operating conditions. The 61:1 gear ratio provides effective torque multiplication and controlled speed.

Common Spline Types Used in Slewing Drives

Slewing drives often incorporate splines to transmit torque efficiently between the drive output and the driven component (like a hydraulic motor, electric motor, or pinion gear). Two primary spline types are prevalent:

Involute Splines:

Design: Feature teeth with curved, involute profiles similar to standard gear teeth. The flanks of the teeth are designed to roll against each other.

Advantages: Provide high torque transmission capacity and excellent centering capability. The curved profile allows for slight misalignment tolerance and smooth engagement/disengagement. They distribute load more evenly across multiple teeth due to the profile contact, leading to lower stress concentrations and higher fatigue strength. Involute splines are highly standardized (e.g., ANSI B92.1, DIN 5480, ISO 4156), ensuring interchangeability and wide availability of mating components. They generally operate more quietly than straight-sided splines.

Disadvantages: Typically more complex and expensive to manufacture than straight-sided splines due to the precision required for the involute profile.

Typical Use: The preferred choice for high-torque applications requiring precision, smooth operation, durability, and reliable centering, such as connecting powerful hydraulic motors or high-precision gearboxes to the slewing drive input.

Straight-Sided (Parallel) Splines:

Design: Feature teeth with straight, parallel sides and flat tops and bottoms (lands). The sides of the teeth bear the load.

Advantages: Simpler and generally less expensive to manufacture than involute splines. Easier to broach or mill. Can be designed for sliding or fixed connections.

Disadvantages: Have lower torque capacity per unit size compared to involute splines due to higher stress concentrations at the root and corners. Less tolerant of misalignment. Require precise alignment during assembly. The straight sides can lead to higher wear and potential fretting corrosion, especially under vibration or cyclic loading. Centering is usually achieved by a close fit or a pilot diameter, not inherently by the spline profile itself. Can be noisier than involute splines.

Typical Use: Suitable for lower to medium torque applications, cost-sensitive designs, or situations requiring simple sliding motion (e.g., some linear actuator connections). Often found in less demanding or budget-oriented drive connections.

Open Housing Slewing Drive S9 Features

The S9 offers a compelling combination of performance, practicality, and value:

Enveloping Worm Design: Simultaneous multi-tooth engagement (4-5 teeth) delivers enhanced output torque (6.5 kN.m), holding torque (38.7 kN.m), and tilting moment capacity (33.9 kN.m) for its compact size.

Inherent Self-Locking: The efficient worm gear geometry provides reliable self-locking when power is off, ensuring load stability and safety critical for lifting and positioning.

Open Housing Design: Provides superior accessibility for visual inspection, lubrication (through accessible ports), and maintenance of the worm gear mesh. Simplifies troubleshooting and servicing.

Lightweight Construction: The open structure and optimized design result in a significantly lower weight (39 kg) compared to equivalent enclosed slewing drives, ideal for weight-sensitive applications.

Robust Load Capacity: Engineered to handle substantial combined loads: static axial load (338 kN), static radial load (135 kN), dynamic axial load (81 kN), and dynamic radial load (71 kN).

Integrated Design: Combines bearings, gearing, and mounting structure into a single pre-assembled unit, simplifying installation and system integration.

Effective Gear Ratio: The 61:1 reduction provides a strong balance of torque multiplication and reasonable rotational speed control.

Durability: Manufactured from quality materials with precision machining to ensure reliable service life under typical medium-duty conditions.

Cost-Effectiveness: The open design often translates to a more economical solution compared to fully sealed drives of similar capacity, while still offering core performance benefits.

Open Housing Slewing Drive S9 Applications

The S9's blend of performance, accessibility, and lightweight design makes it well-suited for various medium-duty applications:

Aerial Work Platforms (AWPs): Powers the rotation of platforms on boom lifts, scissor lifts, and smaller spider lifts. Its self-locking ensures safety, while the lightweight design helps maximize platform payload or machine efficiency. Easy access for lubrication is beneficial in rental fleets.

Light to Medium Mobile Cranes: Used in smaller truck-mounted cranes or knuckle boom cranes for slewing functions. Provides reliable torque and holding power for safe lifting operations.

Material Handling Equipment: Drives rotation on medium-duty industrial turntables, rotators for grabs or clamps, positioning tables, and automated guided vehicle (AGV) docking stations.

Construction & Agricultural Machinery: Powers rotation for attachments on compact excavators, small drilling rigs, agricultural spreaders, or irrigation systems where weight and accessibility are considerations.

Solar Tracking Systems: Used in single-axis or smaller dual-axis solar trackers, providing the necessary torque for panel positioning with the benefit of easier field maintenance.

Industrial Automation & Robotics: Integrates into robotic welding cells, assembly stations, omaterial transfer systems requiring precise rotational indexing under moderate loads. The open housing aids integration and maintenance.

Stage & Entertainment Technology: Powers rotating platforms, lighting trusses, or set pieces where reliable, safe motion and ease of maintenance are important.

Marine Equipment (Sheltered): Suitable for deck equipment like small cranes, winches, or davits on smaller vessels operating in less exposed environments, benefiting from easy servicing.

What Factors Influence the Price of Open Housing Slewing Drive S9?

The cost of the S9 is influenced by several factors related to its design, manufacturing, and market:

Material Costs: The primary driver includes the cost of steel for the slewing ring races, worm wheel, and structural housing. Case-hardened steel for the worm shaft and specific bearing steel grades also contribute. While lighter, material costs remain significant.

Manufacturing Processes: Precision machining of the worm wheel and worm shaft, grinding operations for the gear teeth and worm profile, heat treatment processes (case hardening, tempering), and bearing manufacturing all add cost. The open housing might simplify some casting/machining compared to complex enclosures.

Component Quality & Sourcing: The cost of high-quality bearings (handling 338 kN axial static load) and precision gears directly impacts the price. Reliable seals (where used) add cost.

Gear Ratio: The standard 61:1 ratio requires specific gear sets. Alternative ratios would necessitate different manufacturing tooling and setups, affecting cost.

Scale of Production & Order Volume: As a standardized component, higher production volumes generally lead to lower unit costs due to economies of scale. Larger customer orders typically secure better pricing.

Customization: Modifications from the standard S9 design (e.g., special mounting flanges, unique shaft outputs, specific sealing requirements, alternative surface treatments, or custom lubrication systems) incur additional engineering and production expenses.

Quality Control & Testing: Rigorous in-process and final inspection procedures, along with any specific performance testing (e.g., load testing, backlash measurement to ≤0.17°), contribute to the overall cost but ensure reliability.

Market Competition & Brand Value: Pricing is influenced by the competitive landscape within the medium-duty slewing drive market. Established manufacturers with strong reputations for quality and reliability may command a slight premium.

Supply Chain & Logistics: Costs associated with raw material procurement, component sourcing, and final product distribution influence the final price.

Open Housing Slewing Drive S9 Supplier

LYRADRIVE is a specialized manufacturer focused on the design and production of high-quality slewing drives and bearings, including the practical Open Housing Slewing Drive S9 series. The company utilizes expertise in gear technology and mechanical design to deliver reliable rotational solutions tailored for medium-duty applications where performance, accessibility, and value are key. LYRADRIVE emphasizes robust engineering, consistent manufacturing quality, and the use of durable materials to ensure their S9 drives meet the performance specifications required for dependable operation in target industries like aerial platforms and material handling