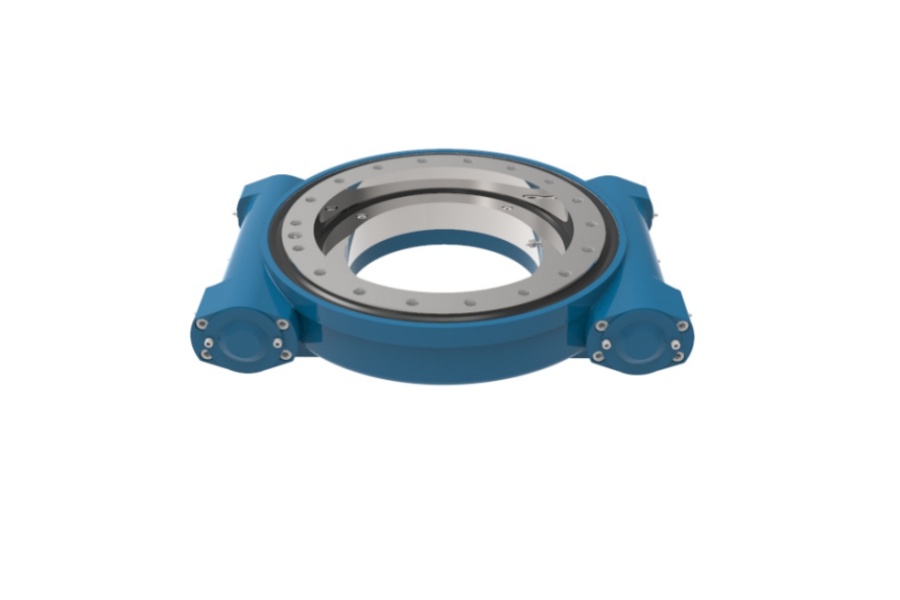

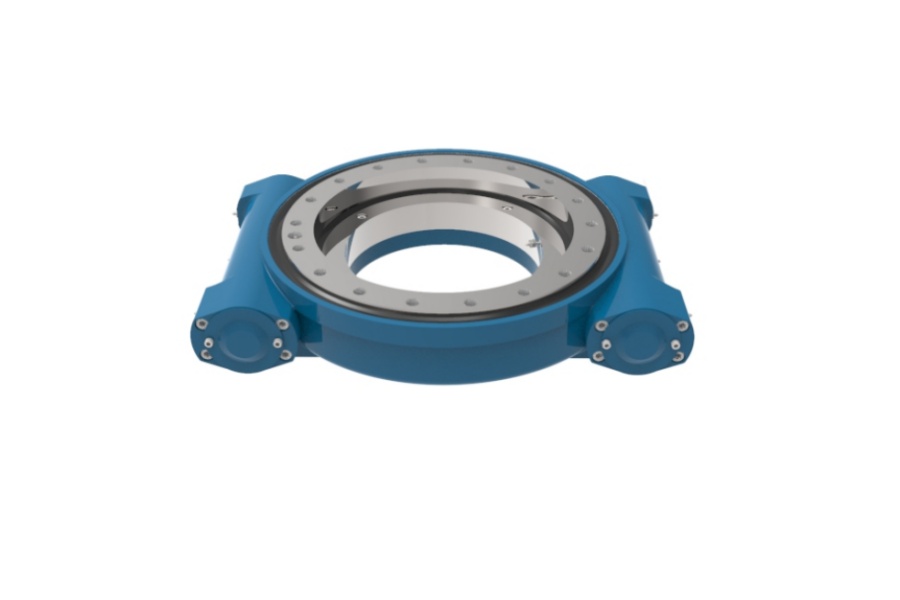

Double Worm Slewing Drive WED14 Enhanced Power and Precision

What is Double Worm Slewing Drive WED14?

Double Worm Slewing Drive WED14 is an advanced, compact drive unit engineered to deliver exceptionally high output torque, holding torque, and resistance to tilting moments through its unique dual-worm gear mechanism driving a central worm wheel. Unlike conventional single-worm drives, the WED14 features two opposing input worms engaging the wheel simultaneously. This configuration distributes load more evenly, drastically increasing drive capacity and stability while maintaining the same physical installation envelope as the WE14 series for straightforward upgrades. Housed within a robust, sealed structure, it integrates high-precision gearing and large-diameter slewing bearings to handle combined axial, radial, and moment loads efficiently.

Common Worm Gear Types in Slewing Drive Design

The performance and characteristics of a worm gear slewing drive hinge critically on the type of worm gear employed. Three primary types are prevalent:

Cylindrical Worm (ZA, ZN, ZI profiles): Features a straight or involute profile in the axial section. Known for good manufacturability and efficiency in single-start designs. Can be prone to higher friction and wear in high-load scenarios compared to other types. Often used where cost-effectiveness is a priority.

Conical (Hourglass) Worm (ZK profile): Characterized by a throated shape that envelops the worm wheel more effectively. This geometry allows for multiple tooth contact points simultaneously, significantly increasing load-carrying capacity and reducing tooth pressure. Offers smoother operation, lower noise, and greater efficiency than cylindrical worms, making it ideal for high-torque, high-precision applications like the WED14.

Plane Worm (ZC profile): Less common in heavy-duty slewing drives, this type involves a worm generated by a planar surface. It offers specific meshing advantages but is generally more complex and costly to manufacture.

The Double Worm Slewing Drive WED14 typically utilizes high-precision conical (hourglass) worm gears. This choice is fundamental to achieving its exceptional torque density, smooth motion transmission, minimal backlash, extended service life, and ability to handle the substantial forces generated by its dual-worm design.

Key Features of the Double Worm Slewing Drive WED14

The WED14 stands out due to a combination of innovative design and robust engineering:

Dual Worm Gear Mechanism: The core innovation. Two opposing worms drive the central wheel, effectively doubling the contact area and load distribution. This translates directly into:

Remarkably High Torque Output: Achieves 16.2 kN.m output torque.

Exceptional Holding Torque: Provides a massive 82 kN.m of static holding force, crucial for safety in suspended loads or precise positioning.

Superior Tilting Moment Resistance: Withstands up to 71.2 kN.m, ensuring stability under significant off-center loads.

Reduced Wear & Enhanced Rigidity: Load sharing minimizes stress on individual gear teeth, leading to longer life and reduced backlash over time.

Inherent Backlash Reduction: The opposing action of the worms helps compensate for minor clearances, resulting in tighter, more precise motion control.

Outstanding Load Capacity: Engineered for extreme service:

Static Loads: Axial: 960 kN, Radial: 360 kN.

Dynamic Loads: Axial: 230 kN, Radial: 200 kN.

High Precision: Offers tracking precision ≤ 0.13°, essential for applications requiring accurate angular positioning and repeatability.

Compact & Efficient Design: Delivers its immense power within a surprisingly compact and lightweight (86 kg) footprint relative to its capabilities, simplifying integration.

Self-Locking Capability: The worm gear design provides a natural self-locking feature when the input is not powered, preventing unintended rotation of the driven load and enhancing operational safety.

High Sealing Integrity (IP65): Effectively protected against dust ingress and low-pressure water jets from any direction, ensuring reliable operation in harsh environments like construction, mining, and marine applications.

Drive Flexibility: Compatible with various drive sources, including hydraulic motors and electric motors (geared or direct), offering versatility for different power systems.

High Gear Ratio (86:1): Provides significant speed reduction and torque multiplication from the input source.

Applications of the Double Worm Slewing Drive WED14

The WED14's combination of power, precision, and durability makes it indispensable in numerous demanding sectors:

Heavy Construction & Mining Equipment: Excavator superstructures, drilling rig turntables, heavy-duty material handling arms, conveyor swing mechanisms, mining shovel positioning.

Lifting Technology: Shipboard cranes, mobile harbor cranes, industrial gantry crane slewing, offshore pedestal cranes, heavy-duty lifting rotators.

Marine & Offshore: Deck machinery, winch positioning systems, A-frame slew drives, sonar array rotation, offshore access equipment.

Renewable Energy: Solar tracker azimuth drives (especially for large, high-wind-load panels), small-to-medium wind turbine yaw and pitch control mechanisms (subject to specific load verification).

Defense & Aerospace: Radar antenna positioning, missile launcher turntables, communication dish drives, heavy weapon station traverse.

Agriculture: Center pivot irrigation system drive units, large grain conveyor swing drives, heavy-duty sprayer boom positioning.

Industrial Automation: Heavy-duty indexing tables, robotic welding positioner drives, large material handling turntables.

Factors Influencing Double Worm Slewing Drive WED14 Pricing

The cost of a WED14 unit is determined by several key factors:

Material Specifications: The grade and quality of steel used for the worm, wheel, housing, and slewing bearing rings significantly impact cost. Higher-grade alloys for extreme wear resistance or corrosion protection increase price.

Manufacturing Precision & Quality Control: Achieving the required ≤0.13° precision and ensuring high-quality gear tooth profiles necessitates advanced machining processes and rigorous inspection, contributing to cost.

Heat Treatment Processes: Specialized hardening and finishing treatments (like case hardening, grinding, lapping) for the worm and wheel gears are essential for durability and performance but add to manufacturing expense.

Bearing Quality & Sealing: The specification of the integrated slewing bearing (internal design, roller type, raceway hardening) and the effectiveness of the sealing system (IP65) are major cost components.

Customization: While the WED14 has a standard design, modifications such as special input shaft configurations, custom mounting flanges, specific lubrication ports, special surface coatings (e.g., corrosion protection), or unique sealing requirements add cost.

Order Volume: Economies of scale apply; larger production runs typically reduce the unit cost.

Market Factors: Fluctuations in raw material costs (especially steel), energy prices, and overall manufacturing demand can influence pricing.

Supplier Expertise & Reputation: Established manufacturers with proven expertise in high-precision, heavy-duty drives like the WED14 often command a premium based on reliability, engineering support, and warranty.

Reliable Supplier of Double Worm Slewing Drive WED14

For robust and high-performance Double Worm Slewing Drives like the WED14, LYRADRIVE stands as a reputable manufacturer. They specialize in the engineering and production of precision slewing drives for demanding global applications. LYRADRIVE focuses on delivering solutions characterized by high load capacity, durability, and precise motion control, utilizing advanced manufacturing techniques and stringent quality standards. Their product range, including the WED14 series, is designed to meet the rigorous requirements of heavy industry, lifting, renewable energy, and specialized automation, offering customers reliable drive technology backed by technical expertise. Choosing a supplier like LYRADRIVE ensures access to proven drive solutions engineered for critical performance.