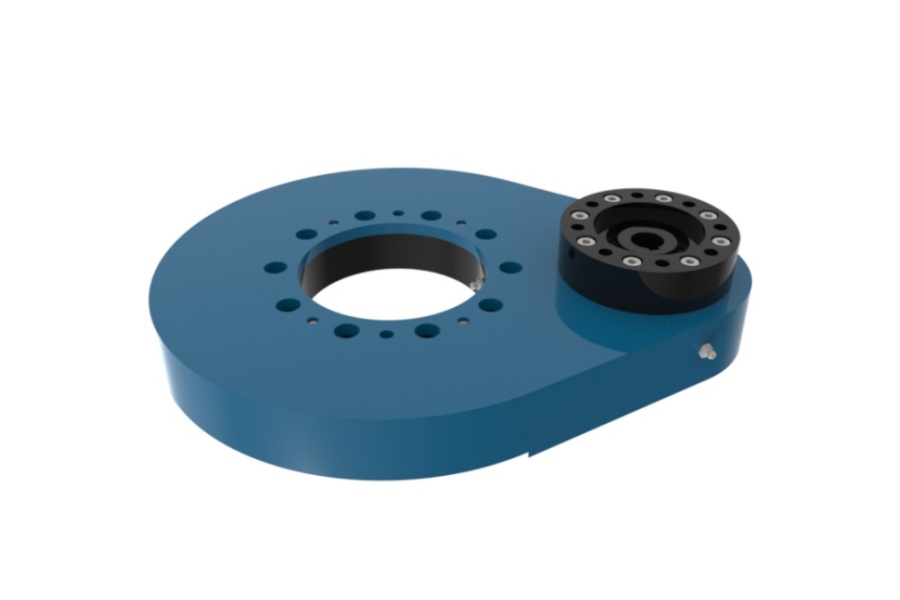

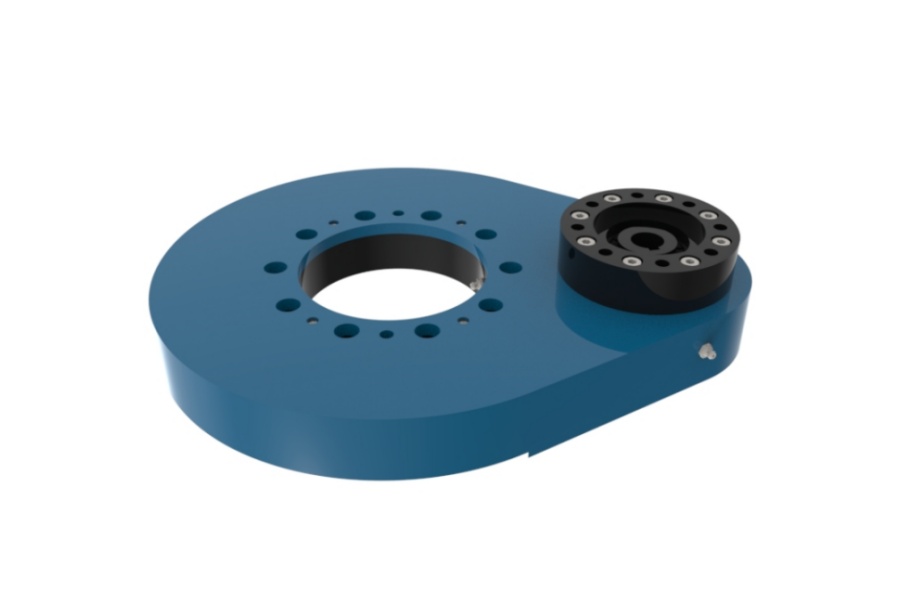

Lightweight Slewing Ring Gear Drive SP-I 0229 Precision Rotation for Demanding Applications

What is Lightweight Slewing Ring Gear Drive SP-I 0229

Lightweight Slewing Ring Gear Drive SP-I 0229 represents a specialized category of slewing drives characterized by its external spur (or straight-cut) gear design integrated directly with a compact slewing ring bearing. Unlike worm-driven slewing drives, the SP-I 0229 utilizes a meshing pinion gear (Z1=15 teeth) driving a large external gear ring (Z2=81 teeth) mounted on the slewing ring's outer race. This configuration provides a direct and efficient 5.4:1 speed reduction. Designed specifically for scenarios demanding higher rotational speeds (up to 40 RPM) and smooth operation under moderate axial and radial loads, its defining feature is its remarkably low weight of just 35 kg. The unit incorporates a fully sealed housing (rated IP65), protecting the internal gearing and bearing from environmental contaminants like dust and moisture. This integrated, unitized design simplifies installation, minimizes maintenance requirements, and offers a reliable, cost-effective solution for precise indexing and continuous rotation in automation, material handling, and various industrial machinery.

Key Gear Design Considerations in Spur Gear Slewing Drives

The performance, efficiency, and longevity of a spur gear slewing drive like the SP-I 0229 hinge critically on the design and manufacturing quality of its gears. Several fundamental factors must be meticulously addressed:

Gear Module (Size): The module (M=4 mm for SP-I 0229) defines the size and strength of the gear teeth. Selecting the correct module involves balancing load capacity requirements with size constraints and desired gear ratio. Larger modules handle higher loads but increase the drive's overall size and weight.

Tooth Profile Accuracy: Precise involute tooth profiles are essential for smooth meshing, minimal noise and vibration, efficient power transmission, and reduced wear. High-precision machining (hobbing, shaping, grinding) is required to achieve the necessary profile accuracy and surface finish.

Gear Material and Heat Treatment: Gears must be manufactured from high-quality steel alloys (e.g., case-hardening steels like 20MnCr5 or similar) to withstand contact stresses and bending loads. Appropriate heat treatment processes like carburizing and hardening followed by tempering are crucial to achieve a hard, wear-resistant surface while maintaining a tough core to prevent tooth breakage.

Tooth Surface Hardness and Finishing: Achieving a high surface hardness (typically 58-62 HRC) through carburizing/hardening significantly enhances wear resistance and pitting resistance. Subsequent grinding or honing improves surface finish, reduces friction, and further minimizes noise and wear.

Backlash Control: Backlash is the small clearance between meshing teeth. While some backlash is necessary to prevent jamming and allow for lubrication, excessive backlash leads to positioning inaccuracy, impact loads, noise, and accelerated wear. The design and manufacturing process must carefully control and specify acceptable backlash limits for the application. Preloaded bearings within the slewing ring also contribute to overall system rigidity and minimal play.

Lubrication: Effective lubrication is vital to minimize friction, dissipate heat generated by sliding and rolling contact, and prevent wear and corrosion. The lubrication system (grease type, quantity, replenishment method) must be designed for the drive's operating environment, speed, and load. The sealed design of the SP-I 0229 ensures lubricant is retained and contaminants are excluded.

Load Distribution: The design must ensure even load distribution across the gear teeth to prevent premature failure due to localized overloading. This involves precise alignment of the pinion and gear ring, adequate bearing support, and accurate gear tooth geometry.

Dynamic Load Capacity: Gears must be rated not only for static loads but also for the dynamic loads encountered during operation, including starting, stopping, reversing, and potential impact loads. The calculated bending strength and surface durability must exceed the anticipated dynamic stresses.

Key Features of Lightweight Slewing Ring Gear Drive SP-I 0229

The SP-I 0229 is defined by a set of features optimized for performance, reliability, and ease of integration in space and weight-sensitive applications:

Exceptional Lightweight Design: Weighing only 35 kg, the SP-I 0229 offers a significant advantage in applications where minimizing overall system weight is critical, such as robotic arms, automated platforms, and mobile equipment. This lightweight construction is achieved through optimized component design and material selection without compromising core strength.

High-Speed Capability: Engineered for faster rotation compared to typical worm gear drives, the SP-I 0229 supports speeds up to 40 RPM. This makes it ideal for applications requiring rapid indexing, scanning, or continuous motion, such as automated assembly lines, packaging machinery, and inspection systems.

Efficient Spur Gear Transmission: The direct meshing of the pinion (Z1=15) and external gear ring (Z2=81) provides a highly efficient 5.4:1 speed reduction with minimal energy loss compared to worm gear mechanisms. This efficiency translates to lower power requirements and reduced operating costs.

Robust Torque Handling: Delivers a maximum output torque of 2860 N.m and a standard nominal torque of 2500 N.m, with a matching maximum holding torque of 2860 N.m. This provides ample power for positioning and driving loads in its designed capacity range.

Significant Load Capacity: Despite its lightweight profile, the SP-I 0229 offers substantial load ratings: a static axial load capacity of 440 kN, static radial load of 155 kN, dynamic axial load of 170 kN, and dynamic radial load of 145 kN. This enables it to handle significant forces encountered in industrial automation and material handling.

IP65 Sealed Unit: The drive is fully enclosed within a housing providing an IP65 environmental protection rating. This effectively seals out dust and protects against water jets from any direction, ensuring reliable operation in demanding industrial environments and significantly extending component life by preventing contamination ingress.

Integrated Unitized Design: The SP-I 0229 comes as a complete, pre-assembled unit integrating the slewing ring bearing and gearing. This simplifies installation, reduces the need for complex alignment procedures, minimizes potential points of failure, and streamlines the supply chain.

Minimal Maintenance: The sealed construction and high-quality internal lubrication are designed for long service life with minimal maintenance intervention. This reduces downtime and operational costs over the drive's lifespan.

Precision Positioning: The spur gear design combined with high-quality manufacturing ensures smooth and accurate rotational positioning, suitable for applications requiring repeatable motion.

Flexible Drive Input: Accommodates various drive sources, including electric motors (with compatible mounting flanges) and hydraulic motors, offering versatility for different power systems within the target application range.

Diverse Applications of Lightweight Slewing Ring Gear Drive SP-I 0229

The unique combination of light weight, high speed, efficiency, and integrated sealing makes the SP-I 0229 exceptionally well-suited for a broad range of modern industrial applications:

Industrial Automation & Robotics: Powers the rotation of robotic arms (especially lighter payload arms or end-of-arm tooling), indexing tables for assembly stations, automated welding positioners, palletizing/depalletizing systems, and precision positioning stages in testing and inspection equipment. Its speed and accuracy are key assets.

Material Handling & Logistics: Drives rotating platforms on automated guided vehicles (AGVs) and autonomous mobile robots (AMRs), powers turntables for conveyor sorting systems, operates rotating sections in automated storage and retrieval systems (AS/RS), and controls the rotation of light to medium-duty pallet wrappers and strapping machines.

Packaging Machinery: Provides reliable rotation for filling carousels, labeling turntables, capping heads, and inspection stations within high-speed packaging lines, benefiting from its speed capability and sealed design.

Medical & Laboratory Equipment: Used in the precise rotation of imaging components (like C-arms or scanner gantries where weight is critical), sample handling turntables, and positioning stages in diagnostic or research equipment, valued for its smooth motion and cleanliness (sealed unit).

Semiconductor Manufacturing: Employed in wafer handling robots, precision inspection stages, and other equipment within cleanroom environments requiring reliable, low-particulate motion (benefiting from the sealed IP65 design).

Light Construction & Agricultural Equipment: Powers rotation functions in compact telehandlers, small aerial work platforms (AWPs), irrigation system components, and specialized attachments requiring efficient, moderate torque rotation.

Renewable Energy - Solar Tracking (Light Duty): Suitable for driving the azimuth rotation of smaller solar panel arrays or single-axis trackers where weight and efficiency are important considerations.

Display & Entertainment: Powers rotating platforms for exhibits, retail displays, and stage machinery where quiet, reliable, and compact rotation is needed.

Defense & Aerospace (Auxiliary Systems): Used in radar or sensor positioning mounts, camera gimbals, and hatch mechanisms on smaller platforms where weight savings are crucial.

Factors Influencing Lightweight Slewing Ring Gear Drive SP-I 0229 Pricing

The cost of the SP-I 0229 is influenced by several factors related to its design, materials, manufacturing, and customization:

Base Model Specifications: The standard SP-I 0229 configuration, with its defined torque ratings (Md max=2860 N.m, Md nom=2500 N.m), load capacities (Co ax=440 kN, Co rad=155 kN, etc.), gear ratio (5.4:1), weight (35 kg), IP65 sealing, and integrated unit design, establishes the fundamental price point.

Material Selection: The use of high-quality steel alloys for the gears (requiring precise heat treatment like carburizing and hardening) and the slewing ring components (races, balls), along with durable sealing materials (e.g., nitrile or Viton seals), significantly impacts material costs. Aluminum alloys may be used strategically in housings for weight savings.

Precision Manufacturing & Finishing: Achieving the necessary gear tooth profile accuracy (involute profile), surface finish (often requiring grinding or honing after heat treatment), precise bearing raceway geometry, and controlled gear backlash demands advanced machining processes, skilled labor, and stringent quality control, contributing substantially to manufacturing costs.

Heat Treatment Complexity: The carburizing, hardening, and tempering processes for the gears are energy-intensive and require careful control to achieve the required hardness depth and core properties without distortion, adding cost.

Integrated Unitized Design: While offering significant installation and reliability benefits, the pre-assembled, sealed unit design involves additional manufacturing steps (sealing, pre-lubrication, final testing) compared to supplying separate components.

Level of Customization: While the SP-I 0229 is often offered as a standard unit, potential customizations can affect price:

Special Mounting Interfaces: Custom flange patterns, bolt holes, or pilot diameters on the fixed or rotating rings.

Alternative Sealing: Upgraded seals for specific chemical resistance or extreme temperatures, though IP65 is standard.

Special Lubrication: Specific grease types for extreme temperatures or extended life.

Integrated Sensors: Adding encoders, resolvers, or proximity sensors for position feedback.

Surface Coatings: Anti-corrosion coatings (e.g., zinc plating, specialized paints) beyond standard protection, if required.

Modified Gear Ratio (Less Common): While 5.4:1 is standard, significant ratio changes would require different gears, impacting cost.

Order Volume: Economies of scale apply. Larger purchase quantities typically result in a lower unit cost compared to single-unit or small-batch orders.

Supply Chain Costs: Fluctuations in the prices of raw materials (steel, aluminum, specialty alloys), energy, transportation, and logistics influence the final price.

Supplier of Lightweight Slewing Ring Gear Drive SP-I 0229

LYRADRIVE is a recognized global manufacturer specializing in the engineering and production of high-performance slewing drives, slewing bearings, and precision gearing solutions, including the innovative Lightweight Slewing Ring Gear Drive SP-I series exemplified by the SP-I 0229. Focused on delivering reliable and efficient rotational motion, LYRADRIVE caters to diverse industries such as industrial automation, material handling, packaging, renewable energy, and specialized machinery. They leverage advanced manufacturing capabilities and stringent quality control processes to produce components like the SP-I 0229, known for its integrated design, precision, and environmental resilience. LYRADRIVE emphasizes providing solutions that offer ease of integration, reduced maintenance, and long service life, supporting customers in optimizing their equipment performance.