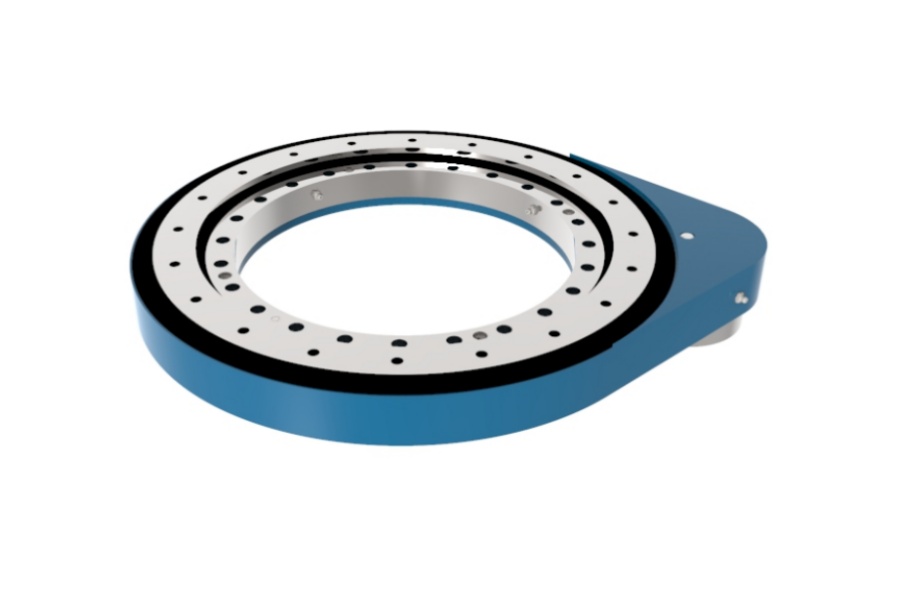

Lightweight Slewing Ring Gear Drive SP-I 0411 High-Efficiency Motion Control

What is Lightweight Slewing Ring Gear Drive SP-I 0411

Lightweight Slewing Ring Gear Drive SP-I 0411 integrates hardened spur/helical gears with a high-capacity slewing ring into a single sealed assembly. Featuring a 4mm module gear system (126-ring/15-pinion teeth) and 8.4:1 reduction ratio, it efficiently converts input torque into controlled 360° rotation while supporting combined axial/radial loads up to 700 kN static axial and 265 kN static radial. Its all-aluminum construction reduces inertial resistance, enabling rapid start-stop cycles in robotics and material handling systems.

How Spur Gear Slewing Drives Achieve Self-Locking

Unlike worm gear drives that inherently self-lock due to high friction angles, spur gear drives like the SP-I 0411 require external braking mechanisms for self-locking. This is because:

Low Friction Angle: Spur gears operate with rolling friction (friction angle < 5°), allowing back-driving under load.

Kinematic Reversibility: The efficiency (η > 90%) enables output torque to reverse-drive the input shaft.

To ensure reliable self-locking in SP-I 0411 applications:

Integrated Disc Brakes: Electromagnetic or hydraulic brakes are mounted on the input shaft to halt rotation.

Backlash Control: Preloaded tapered roller bearings minimize gear play, enhancing brake responsiveness.

Static Friction Utilization: At zero motion, gear tooth micro-deformation creates "sticktion" that temporarily resists movement until external torque exceeds 4450 N·m (Mh value).

Key Features of Lightweight Slewing Ring Gear Drive SP-I 0411

High-Speed Capability: Supports rotation up to 30 rpm – 50% faster than conventional slewing drives.

Optimized Torque Output: Delivers 4,450 N·m max torque (3,205 N·m nominal) for abrupt load transitions.

Dynamic Load Resilience: Axial dynamic load capacity of 215 kN and radial dynamic load of 180 kN endure cyclic stresses.

Ultra-Lightweight Design: 50 kg mass reduces inertial energy loss by 40% versus steel alternatives.

Environmental Robustness: Triple-labyrinth seals with grease-purged cavities achieve IP65 protection against dust/water ingress.

Maintenance-Free Operation: Lifetime-lubricated gears and pre-adjusted bearing clearances eliminate field servicing.

Applications of Lightweight Slewing Ring Gear Drive SP-I 0411

Automated Assembly Lines: Powers 30 rpm rotary indexing tables for precision part positioning.

Packaging Machinery: Drives high-speed palletizing arms handling loads up to 700 kN axial force.

Solar Tracking Systems: Enables rapid azimuth adjustment in dual-axis trackers (215 kN dynamic axial load rating).

Mobile Crane Jibs: Replaces hydraulic swing motors with electric actuation for smoother motion control.

Medical Robotics: Provides vibration-free rotation for surgical imaging platforms requiring <0.1° positioning accuracy.

Price Determinants for Lightweight Slewing Ring Gear Drive SP-I 0411

Material Costs: Aircraft-grade aluminum (6061-T6) housings vs. cast iron impact pricing by 18-22%.

Gear Manufacturing: Precision grinding (DIN 5 standard) adds 15% cost over hobbed gears but extends lifespan 3x.

Load Certification: ISO 281:2007 dynamic load validation increases unit price by 8-12%.

Customization: Optional shaft configurations (splined/keyed) or corrosion-resistant coatings (e.g., Alodine) incur 10-25% premiums.

Order Volume: Batch production (>100 units) lowers per-unit costs by 17% via optimized machining workflows.

Trusted Supplier of Lightweight Slewing Ring Gear Drive SP-I 0311

LYRADRIVE pioneers slewing drive innovation with ISO 9001-certified manufacturing and 14+ years of motion control expertise. Their SP-I series undergoes rigorous FEA simulation and 1,000-hour accelerated life testing, ensuring >100,000 operation cycles under peak loads. Global clients in 35+ countries leverage LYRADRIVE’s turnkey solutions – from 3D CAD model integration to on-site commissioning support – backed by a 24-month performance warranty.