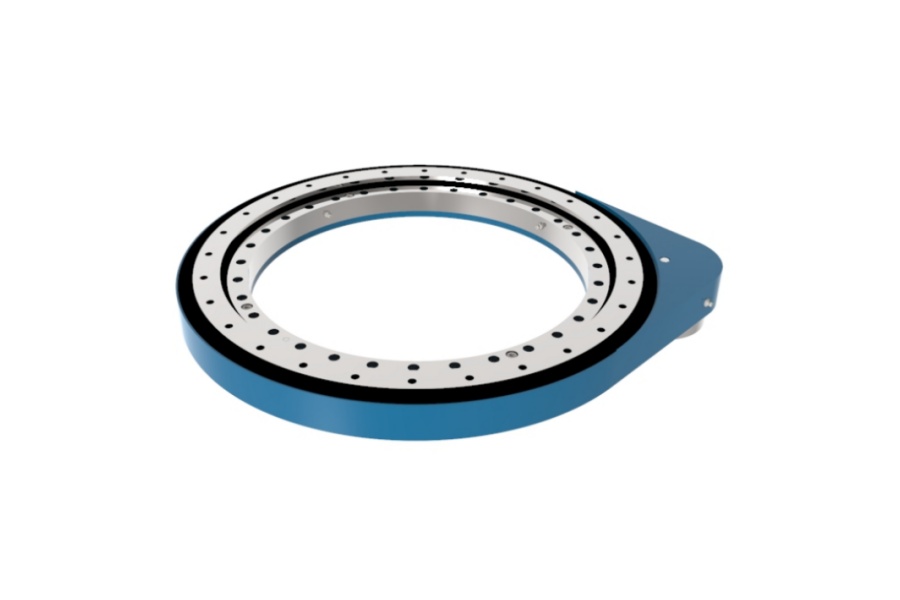

Medium Duty Gear Slewing Drive SP-M 0541 High Torque Precision

What is Medium Duty Gear Slewing Drive SP-M 0541?

Medium Duty Gear Slewing Drive SP-M 0541 is a fully integrated slewing drive system combining a heavy-duty slewing ring bearing, precision spur gearing, advanced sealing, and standardized mounting interfaces into a single pre-lubricated unit. Designed to transmit up to 12,900 Nm of torque while supporting axial static loads of 750 kN and radial static loads of 330 kN, it operates at speeds up to 30 RPM. This drive eliminates complex alignment of separate components, reduces mechanical footprint, and enhances operational reliability in heavy automation, material handling, and construction equipment. It serves as a direct replacement for IMO SP-M 0541 drives.

Backlash Analysis in Gear Slewing Drives

Backlash (gear mesh clearance) critically impacts slewing drive performance. Precise control is essential for:

Positioning Accuracy: Minimal backlash (±0.05°–0.15°) ensures repeatable stops in automation and indexing.

Smooth Operation: Controlled clearance prevents jerky motion and vibration under load reversals.

Load Distribution: Optimized backlash ensures even tooth contact, reducing stress concentrations and pitting.

Noise Reduction: Tightly managed clearance minimizes gear rattle during startup/shutdown.

Longevity: Proper backlash accommodates thermal expansion while preventing tooth impact damage.

SP-M 0541 Solution:

Factory pre-setting ensures consistent backlash (0.08–0.12 mm) through precision gear grinding, selective pinion pairing, and preloaded bearing adjustment. This eliminates field adjustments and guarantees performance stability throughout the service life.

Key Features of Medium Duty Gear Slewing Drive SP-M 0541

The SP-M 0541 excels with engineered robustness:

Integrated Heavy-Duty Design: Unifies gearbox, slewing ring, and seals into one rigid unit for simplified integration and structural integrity.

Exceptional Load & Torque Capacity:

Axial Static Load (Co ax): 750 kN

Radial Static Load (Co rad): 330 kN

Maximum Torque (Md max): 12,900 Nm

Maximum Holding Torque (Mh): 12,950 Nm

Standard Operating Torque (Md nom): 9,870 Nm

Precision Gear Transmission:

Module (M): 6 mm

Ring Gear Teeth (Z2): 105

Pinion Teeth (Z1): 15

Gear Ratio (i): 7

Optimized Speed & Control: Supports smooth rotation up to 30 RPM with pre-set backlash for accurate positioning.

IP65 Sealed Protection: Full-perimeter sealing protects gears and bearings from dust, moisture, and contaminants.

High-Strength Materials: Forged 42CrMo4 alloy steel rings and case-hardened 18CrNiMo7-6 gears (surface hardness 60±2 HRC).

Reduced Maintenance: Pre-lubricated for life with sealed internals, minimizing downtime.

Drive Flexibility: Compatible with hydraulic motors or IEC/NEMA electric motors.

Interchangeability: Direct replacement for IMO SP-M 0541 units.

Weight-Optimized Construction: 103 kg mass balances durability and ease of integration.

Applications of Medium Duty Gear Slewing Drive SP-M 0541

Ideal for high-stress, precision-demanding environments:

Heavy Construction: Tower crane slewing, drilling platform rotation, and pile driver positioning.

Material Handling: Scrap handling crane grapples, bulk material reclaimers, and rotating dock levelers.

Mining & Quarrying: Crusher oscillation systems, stacker-reclaimer booms, and conveyor swivel drives.

Industrial Automation: Heavy welding positioners (10+ ton capacity), forging manipulators, and press turntables.

Renewable Energy: Solar tracker azimuth drives and wind turbine nacelle service platforms.

Port Equipment: Container crane spreaders and ship loader luffing systems.

Specialized Machinery: Tunnel boring machine segment feeders, artillery turrets, and heavy-duty test rigs.

Factors Influencing the Price of Medium Duty Gear Slewing Drive SP-M 0541

Cost drivers include:

Material Costs: High-grade forged alloy steel (rings, gears) constitutes 40–50% of the unit price.

Precision Machining: CNC hobbing/grinding of 105-tooth ring gear (6-module) demands specialized tooling and extended machining time (10+ hours).

Heat Treatment: Deep case hardening (1.5–2.0 mm depth) for large-diameter gears in controlled-atmosphere furnaces.

Bearing Components: Triple-row roller bearing configuration for combined 750 kN axial/330 kN radial load capacity.

Backlash Control: Precision grinding, pinion selection, and pre-load adjustment add 15–20% to manufacturing cost.

Sealing System: Multi-labyrinth seals with high-temperature HNBR compounds for IP65 rating.

Quality Assurance: Rigorous testing (torque validation to 15,000 Nm, gear CMM analysis, IP65 certification).

Certifications: ISO 9001/14001 compliance and load rating documentation.

Customization: Non-standard mounting flanges or shaft interfaces increase cost by 20–30%.

Logistics: Weight (103 kg) and dimensional freight costs for global supply chains.

Supplier of Medium Duty Gear Slewing Drive SP-M 0541

LYRADRIVE manufactures the SP-M 0541 to exacting standards, utilizing advanced CNC gear machining and heat treatment processes to ensure certified load ratings, IP65 protection, and precise backlash control. Their integrated production guarantees torque consistency and durability for heavy-duty industrial, automation, and material handling applications.