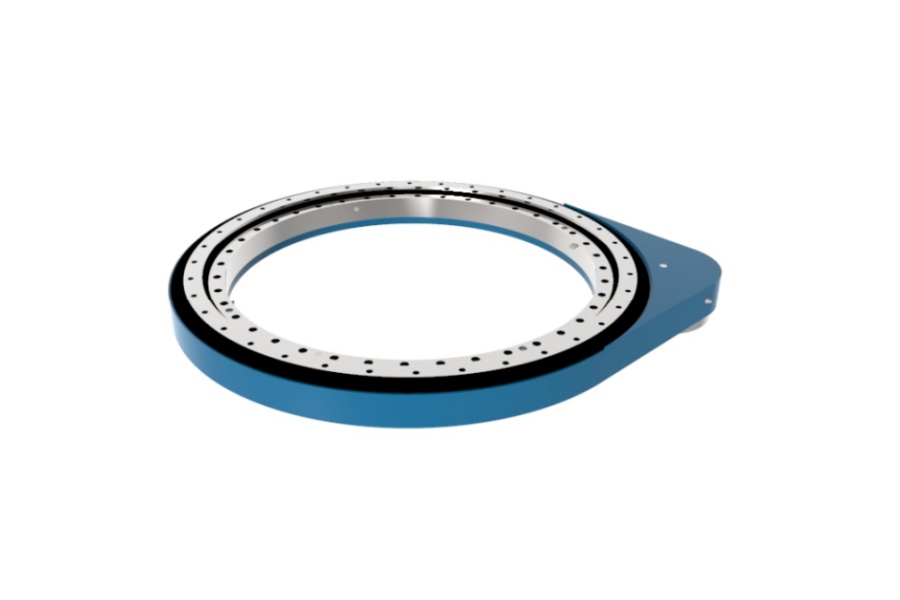

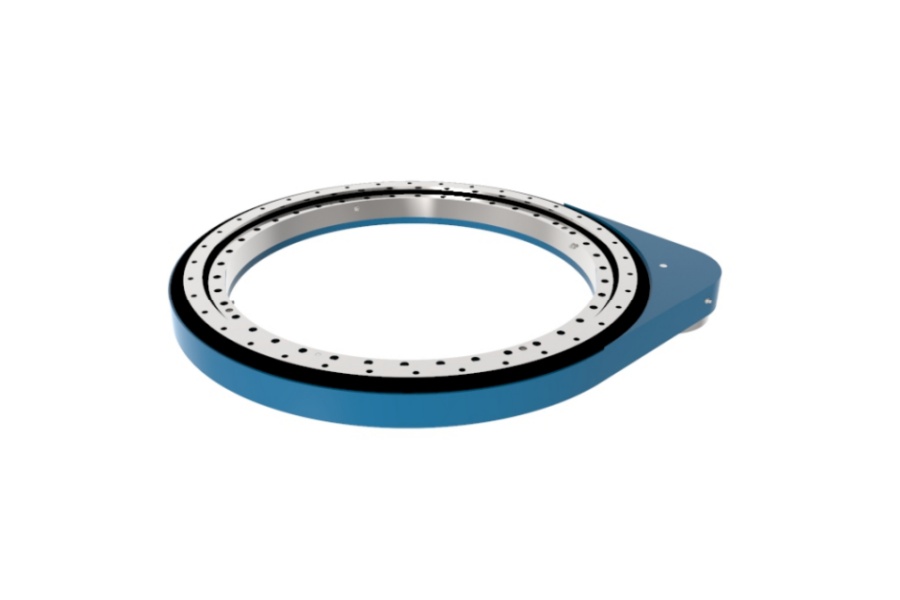

Medium Duty Gear Slewing Drive SP-M 0741 for Demanding Rotary Motion

What is Medium Duty Gear Slewing Drive SP-M 0741

Medium Duty Gear Slewing Drive SP-M 0741 represents a sophisticated class of power transmission components. It functions as a compact, self-contained unit combining a precision gear reduction mechanism with a large-diameter slewing bearing. Engineered for applications requiring reliable 360-degree rotation with high rotational speed capabilities (up to 20 RPM) and substantial load-bearing capacity, it effectively replaces traditional slew ring bearings paired with separate drive pinions. Its core purpose is to simplify mechanical design, enhance system rigidity, improve sealing, and extend service life by integrating critical functions into a single, optimized package. This unit is specifically designed to handle demanding operational conditions found in construction, material handling, automation, and renewable energy sectors.

Causes of Failure in Slewing Ring Bearings for Construction Machinery and Repair Methods

Slewing ring bearings are critical components in construction machinery like excavators, cranes, and concrete pumps, and their failure can lead to costly downtime. Common causes include:

Contamination: Ingress of dirt, water, or abrasive particles due to damaged seals or improper maintenance is a primary cause of premature wear and pitting in raceways and rolling elements.

Lubrication Failure: Insufficient lubrication, use of incorrect lubricant type, or lubricant degradation leads to increased friction, heat generation, adhesive wear (scuffing), and ultimately bearing seizure.

Overloading: Exceeding the bearing's static or dynamic load ratings, often through shock loads or improper machine operation, causes plastic deformation of raceways (brinelling), cracking, or catastrophic failure.

Misalignment: Improper installation resulting in misalignment between the bearing and its mounting structure induces uneven load distribution and excessive stress, accelerating fatigue failure.

Corrosion: Exposure to corrosive environments (saltwater, chemicals) without adequate protection causes surface degradation, pitting, and reduced structural integrity.

False Brinelling: Vibrations during transport or non-operational periods can cause fretting corrosion at the contact points between rolling elements and raceways.

Fatigue: Cyclic loading over time exceeding the material's endurance limit leads to subsurface crack initiation and propagation, resulting in spalling (material flaking off the raceway).

Repair Methods:

Prevention: Strict adherence to maintenance schedules (lubrication, seal inspection), correct operation within load limits, and ensuring proper installation alignment are paramount.

Seal Replacement: Damaged seals should be replaced immediately to prevent contamination ingress.

Relubrication & Flushing: Thoroughly flushing contaminated lubricant and replacing it with the correct type and quantity can sometimes salvage a bearing in early stages of wear.

Raceway Repair: Specialized techniques like grinding or welding followed by precision machining can sometimes repair minor damage, but this is often costly and not feasible for widespread damage.

Component Replacement: Replacing individual damaged rolling elements (balls/rollers) or gear teeth might be possible in some designs, but requires significant expertise.

Complete Bearing Replacement: For severe damage (spalling, cracks, significant wear, brinelling), corrosion, or advanced fatigue, replacing the entire slewing ring bearing or the integrated slewing drive unit is usually the most reliable and cost-effective long-term solution. Units like the SP-M 0741, designed with robust seals (IP65) and integrated protection, inherently reduce these failure risks.

Key Features of Medium Duty Gear Slewing Drive SP-M 0741

The SP-M 0741 distinguishes itself through a combination of robust engineering and user-focused design:

High Torque Capacity: Delivers impressive maximum drive torque (Md max) of 16,980 Nm and a standard nominal torque (Md nom) of 13,100 Nm, suitable for demanding medium-duty applications.

Exceptional Load Handling: Features substantial static load ratings (Radial Co rad: 450 KN, Axial Co ax: 1,080 KN) and dynamic load ratings (Radial C rad: 190 KN, Axial C ax: 205 KN), ensuring stability under heavy and variable loads.

High Rotational Speed: Capable of operating at speeds up to 20 RPM, significantly higher than many traditional slewing bearing solutions, enabling faster cycle times.

Precision Gear Design: Utilizes a module 6 gear system with a pinion (Z1=15 teeth) driving a large internal gear ring (Z2=138 teeth), achieving a high gear ratio (i=9.2) for precise motion control and significant force multiplication.

Integrated & Sealed Unit: Employs a full-seal design, encapsulating the gear meshing and bearing elements within a protected cavity, achieving IP65 ingress protection. This dramatically reduces contamination risks and extends maintenance intervals compared to open slew ring/pinion setups.

Robust Construction: Engineered for durability, with a weight of 135 kg indicating substantial material use and structural integrity.

High Holding Torque: Offers a maximum holding torque (Mh) of 16,980 Nm, ensuring stability and resistance to unintended movement when stationary.

Eliminated Backlash Issues: The integrated design inherently solves the traditional challenge of maintaining precise gear tooth clearance (backlash) between a separate pinion and slew ring, enhancing positional accuracy and reducing wear.

Flexible Drive Options: Can be readily powered by either hydraulic motors or electric motors, providing adaptability to different machine power systems.

Simplified Installation & Maintenance: The unitized design reduces assembly complexity on the OEM side and minimizes points requiring field maintenance.

Applications of Medium Duty Gear Slewing Drive SP-M 0741

The SP-M 0741's blend of speed, torque, load capacity, and robustness makes it ideal for numerous applications requiring reliable rotary motion:

Construction Machinery: Excavator attachments (rotating grabs, crushers, pulverizers), mini crane superstructures, compact loader attachments, concrete pump line rotation.

Material Handling: Rotating platforms for conveyors, indexing tables, medium-duty rotary positioners for welding or assembly, automated guided vehicle (AGV) turntables, palletizing/depalletizing arms.

Forestry Equipment: Harvester and forwarder head rotation, delimber rotation.

Renewable Energy: Solar tracker azimuth drives (especially for larger panels or concentrated systems requiring higher torque), small wind turbine yaw drives.

Industrial Automation: Robotic work positioners, rotary indexing stages for machining/inspection, packaging machinery turntables.

Access & Maintenance: Manlift turntables, inspection camera positioning systems.

Specialty Vehicles: Rotating light towers, antenna positioning systems on service vehicles.

Agriculture: Certain types of sprayer boom rotation or specialized harvesting equipment positioning.

Recycling & Scrap Handling: Grapples, shear rotators on material handlers.

Factors Influencing the Price of Medium Duty Gear Slewing Drive SP-M 0741

The cost of an SP-M 0741 slewing drive is influenced by several key factors:

Material Costs: The price of high-grade alloy steels used for gears, raceways, and structural components significantly impacts the base cost. Fluctuations in global steel markets directly affect pricing.

Manufacturing Complexity: Precision machining of hardened gears and large-diameter bearing races, specialized heat treatment processes, and meticulous grinding operations require advanced equipment and skilled labor, contributing substantially to the cost.

Bearing Quality & Specifications: The quality and source of the internal slewing bearing (roller type, precision grade, hardening depth) are major cost drivers. Higher load ratings and longevity come at a premium.

Gear Quality & Finishing: Precision gear hobbing, shaping, and grinding to achieve the required tooth profile accuracy and surface finish for smooth operation and durability add cost.

Sealing System: High-performance seals capable of achieving IP65 rating reliably under dynamic conditions involve specific materials and design complexity.

Customization: While the SP-M 0741 is a standard model, any deviations (special mounting flanges, custom shaft outputs, specific lubrication ports, special surface treatments) will increase the price.

Order Volume & Contract Terms: Larger volume orders typically command lower unit prices due to economies of scale. Long-term supply agreements can also influence pricing.

Supply Chain & Logistics: Costs associated with sourcing raw materials, components (like seals or bearings if not manufactured in-house), and global shipping impact the final price.

Manufacturer Overhead & Reputation: Established manufacturers with rigorous quality control processes, R&D investment, and strong technical support typically command prices reflecting that value and reliability assurance. The engineering expertise behind the integrated design and its benefits is factored in.

Market Demand & Competition: General industrial demand and the competitive landscape within the slewing drive market can influence pricing strategies.

Supplier of Medium Duty Gear Slewing Drive SP-M 0741

LYRADRIVE is a recognized supplier and specialist in the design and manufacture of high-performance slewing drives, including the Medium Duty SP-M 0741 model. They focus on providing engineered solutions for demanding rotary motion applications across various industrial sectors. LYRADRIVE emphasizes product quality, reliability, and technical support, ensuring their slewing drives meet rigorous performance standards. Their SP-M 0741 is noted for its interchangeability with IMO models, offering flexibility for users. Businesses seeking a robust and efficient medium-duty slewing drive solution can source the SP-M 0741 directly from LYRADRIVE.