Unlocking Precision Rotation with Medium Duty Gear Slewing Drives

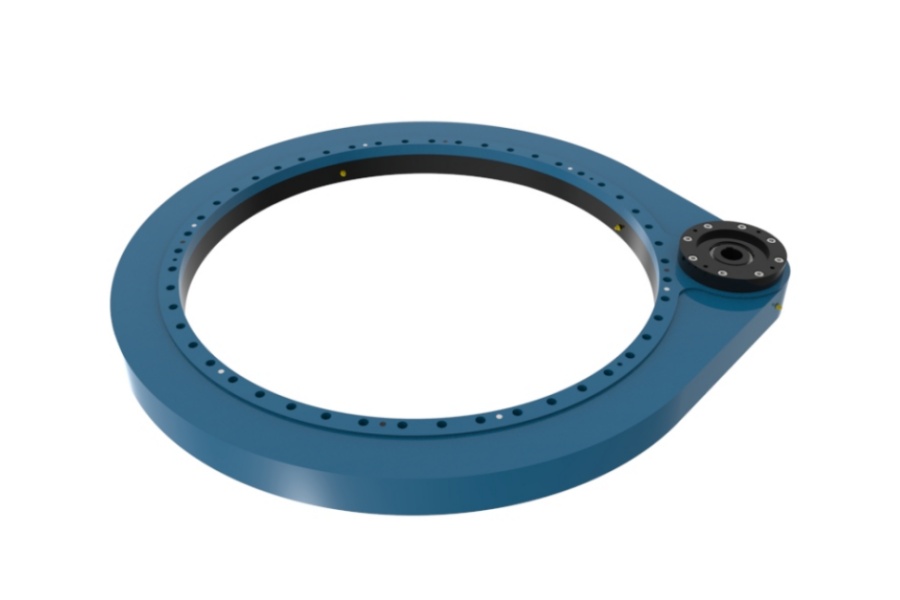

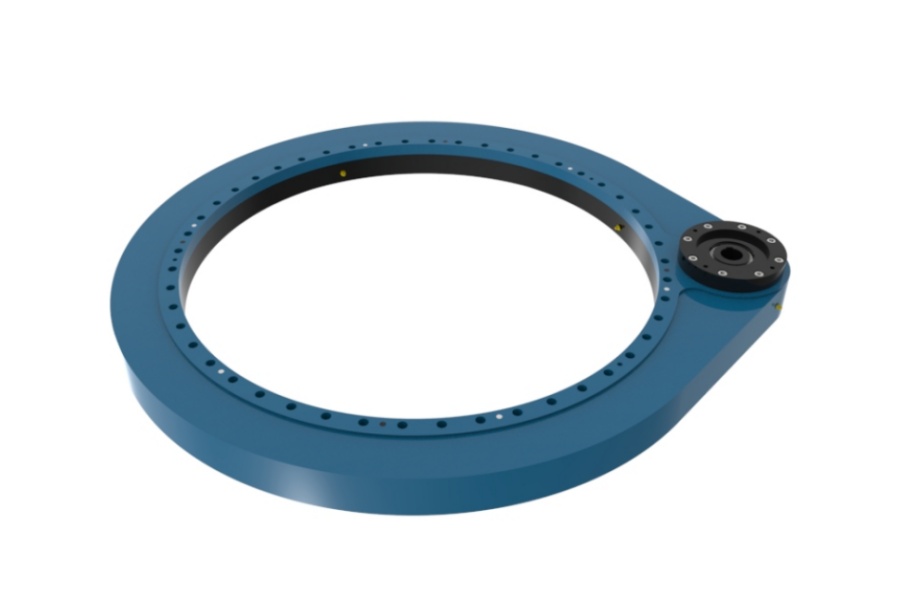

What is Medium Duty Gear Slewing Drive SP-M 0941

Medium Duty Gear Slewing Drive SP-M 0941 integrates a hardened gear reduction system with a large-diameter slewing bearing into a single sealed assembly. This engineered unit efficiently converts high-speed motor input into controlled low-speed, high-torque rotation while supporting substantial combined loads. Its modular design features precision-ground helical or spur gears (Module: 6mm) meshing with an internal gear ring to achieve optimal reduction ratios, eliminating alignment complexities inherent in traditional drive-bearing configurations.

Gear Slewing Drive Installation and Operation Manual

Proper installation ensures peak SP-M 0941 performance and longevity:

Mounting Surface Prep: Ensure machined mounting surfaces are flat (≤0.1mm/m tolerance) and clean. Non-parallel surfaces induce premature bearing stress.

Fastener Protocol: Use grade 10.9 or higher bolts torqued to spec (refer to datasheet values). Apply medium-strength threadlocker to prevent vibrational loosening.

Drive Unit Alignment: Input shaft/motor coupling misalignment must not exceed 0.05mm radial/0.1° angular to prevent gear damage.

Lubrication: Factory-preloaded with synthetic grease (ISO VG 220). Relubricate every 2,000 operational hours via designated ports.

Seal Integrity: Inspect seals biannually. Never operate with damaged seals in contaminant-prone environments (IP65 rating dependent on intact seals).

Break-in Procedure: Run at 25% nominal load for 2 hours initially to distribute lubricant evenly.

Failure to observe these protocols voids warranty.

Key Features of Medium Duty Gear Slewing Drive SP-M 0941

Torque Performance: 16,500 Nm nominal torque (19,800 Nm max) for demanding rotational tasks

Extreme Load Capacity: 1,250 KN axial static load / 530 KN radial static load; 220 KN axial dynamic load / 205 KN radial dynamic load

Precision Gearing: 6mm module helical gears (Pinion Z1=15, Ring Z2=162) achieving 10.8:1 reduction ratio with minimal backlash (<5 arc-min)

High-Speed Capability: Rated for continuous operation at 20 RPM

Corrosion Resistance: Hardened alloy steel components with optional zinc-nickel plating

IP65 Protection: Triple-lip seals and labyrinth barriers exclude dust/water ingress

Weight Optimization: 158 kg compact footprint for space-constrained integration

Maintenance Interval: 10,000-hour relubrication cycle under standard conditions

Primary Applications of Medium Duty Gear Slewing Drive SP-M 0941

Solar Energy: Single-axis solar tracker azimuth drives in utility-scale PV farms

Material Handling: Robotic palletizer rotation modules and automated storage turntables

Construction Machinery: Compact crane jib slewing systems and concrete mixer drum drives

Industrial Automation: CNC index tables and welding positioners requiring ±0.1° repeatability

Transportation: Heavy-duty conveyor swivel mechanisms in mining/logistics

Marine Equipment: Offshore crane boom rotation and hatch cover actuation

Agriculture: Center pivot irrigation drive units and combine harvester attachments

Factors Influencing Medium Duty Gear Slewing Drive SP-M 0941 Price

Material Volatility: Bearing steel (100Cr6) and gear alloy (20MnCr5) spot prices directly impact 45% of unit cost

Heat Treatment: Case hardening depth (1.2-1.8mm) and tempering processes account for 18% of manufacturing expense

Precision Machining: Grinding tolerance (DIN Class 5) adds 22% cost vs standard milling

Customization: Non-standard shaft configurations (splined/hollow) increase price 15-30%

Certifications: CE/ISO 6336 certification adds 8% but enables EU market access

Order Volume: Tiered pricing activates at 50+ units (12% discount)

Logistics: Ocean freight surcharges can add 7-10% to ex-works pricing

Sealing Systems: IP65-compliant seal packages contribute 9% to base cost

Supplier of Medium Duty Gear Slewing Drive SP-M 0941

LYRADRIVE engineers and manufactures the SP-M series slewing drives for global industrial markets. The company’s vertically integrated production facility in Jiangsu, China utilizes CNC gear grinding machines and automated assembly lines to achieve consistent quality in medium-to-heavy duty rotary drives. LYRADRIVE holds ISO 9001:2015 certification and provides technical support for drive integration across solar tracking, construction equipment, and automation sectors. Custom torque/ratio configurations are available for OEM applications