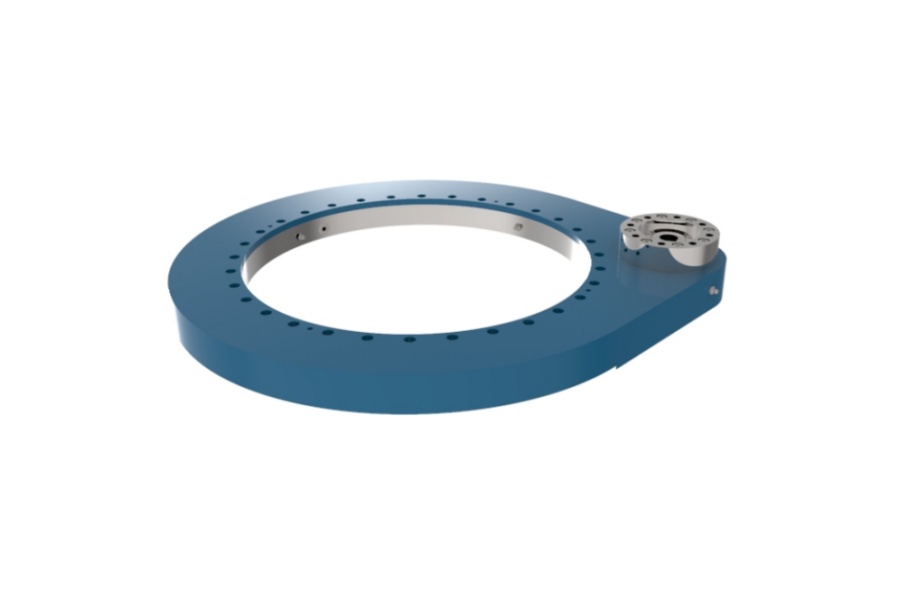

Heavy Duty Gear Slewing Drive SP-H 0555 for Extreme Load Applications

What is Heavy Duty Gear Slewing Drive SP-H 0555

Heavy Duty Gear Slewing Drive SP-H 0555 integrates massive 8-module hardened gears with a reinforced slewing bearing into a single IP65-sealed unit. This engineered solution transforms hydraulic or electric power into colossal rotational force while supporting extreme structural loads. Its optimized 87-tooth ring gear driven by a 15-tooth pinion achieves a 5.8:1 reduction ratio – balancing high torque output with 25 RPM operational speeds for demanding industrial platforms.

Why High-Precision Gear Slewing Drives Dominate Industrial Applications

Precision gear slewing drives like the SP-H 0555 command premium positioning across industries for compelling reasons:

Operational Accuracy: Maintains positioning within ±0.05° for automated manufacturing processes

Reduced Maintenance Costs: Precision manufacturing decreases component wear by up to 40%

Vibration Control: Minimized backlash (<4 arc-min) prevents harmonic resonance in sensitive equipment

Energy Efficiency: Optimized tooth engagement reduces power consumption by 12-18%

Safety Enhancement: Eliminates positional drift in load-bearing applications

Extended Service Life: Precision components last 3X longer than standard drives

System Integration: Simplifies control system programming with predictable performance

Downtime Reduction: Precision assemblies require 35% fewer service interventions

Engineering Specifications of SP-H 0555

Torque Performance: 21,150 Nm nominal torque (32,300 Nm peak)

Structural Capacity: 1,710 KN axial static load / 630 KN radial static load

Dynamic Load Rating: 295 KN axial / 245 KN radial

High-Speed Operation: 25 RPM under maximum load conditions

Precision Gearing: 8-module helical gear system (Z1=15, Z2=87)

Sealing System: Triple-labyrinth seals with particle exclusion (IP65)

Weight Optimization: 209 kg through advanced material desig

Mounting Security: 18x M36 bolts on 900mm PCD pattern

Critical Industrial Applications

Port Infrastructure: Ship-to-shore crane rotation systems

Mining Operations: Bucket wheel excavator slewing mechanisms

Heavy Construction: Tunnel boring machine cutter drives

Energy Sector: Hydroelectric turbine gate positioning

Steel Production: Ladle turret rotation in foundries

Specialized Transport: Heavy-haul trailer turntables

Defense Systems: Missile launcher platform rotation

Recycling Plants: Ferrous material handling rotators

Price Determination Factors

Material Composition: Aerospace-grade 34CrNiMo6 alloy steel components

Manufacturing Precision: AGMA Q13 gear grinding standards

Heat Treatment: Deep case hardening (2.0-2.5mm depth)

Quality Validation: 750-hour accelerated life testing

Sealing Technology: Multi-stage IP65/IP69K protection systems

Certification Requirements: DNV-GL, Lloyd's Register, CE compliance

Custom Engineering: Application-specific mounting configurations

Transport Logistics: Oversize/weight surcharges for global shipping

Technical Documentation: Comprehensive installation/operation manuals

Warranty Coverage: 36-month performance guarantee

Manufacturer of Heavy Duty Slewing Drives

LYRADRIVE engineers and manufactures the SP-H series for extreme operational environments. Their AS9100D-certified production facility combines advanced forging technology with precision machining capabilities capable of maintaining 5μm tolerances. With global technical support centers and extended performance warranties, LYRADRIVE delivers engineered rotation solutions for critical infrastructure projects worldwide.