Heavy Duty Gear Slewing Drive SP-H 0855 Power and Precision

What is Heavy Duty Gear Slewing Drive SP-H 0855

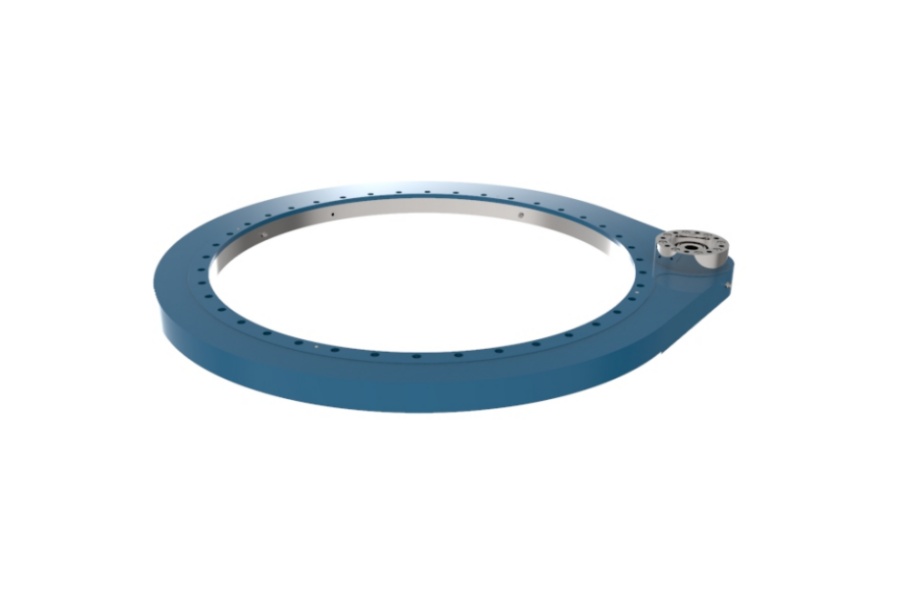

Heavy Duty Gear Slewing Drive SP-H 0855 is a sophisticated, integrated gear reduction system specifically designed for applications demanding high torque transmission, precise positioning, and reliable operation under extreme radial and axial loads. It functions as a complete rotational drive unit, incorporating a robust slewing bearing with integral gearing, precision-machined pinions, and a sealed housing. Engineered for durability, it excels in situations where space constraints exist alongside the need for significant power transfer and controlled rotational movement. Its core purpose is to efficiently transform input power (from hydraulic motors or electric motors) into high-torque, controlled rotational output for heavy machinery platforms and structures.

Analyzing Heat Dissipation Methods for High-Speed Straight Tooth Slewing Drives

Effective heat management is critical for maintaining performance, longevity, and reliability in high-speed straight tooth slewing drives like the SP-H 0855, especially when operating near its maximum rotational speed of 15 RPM under significant load. Friction at the gear meshing points and within the bearings generates substantial heat. Several key methods are employed to ensure efficient heat dissipation:

Optimized Gear Design and Surface Treatment: Precise machining of the straight tooth profiles minimizes friction and uneven contact points that generate excessive heat. Advanced surface treatments, such as specialized gear tooth grinding, superfinishing, or coatings, further reduce friction coefficients and enhance heat transfer away from the contact zone.

Efficient Lubrication Systems: The correct type and quantity of high-performance grease are paramount. Grease acts not only as a lubricant reducing friction but also as a heat transfer medium. The SP-H 0855's sealed design incorporates efficient grease circulation paths within the gear cavity. In extreme duty cycles, automatic lubrication systems ensure consistent grease delivery to critical interfaces, flushing away heat and wear particles. Selecting grease with excellent thermal stability and high-temperature performance is essential.

Thermal Management via Housing Design: The drive housing itself plays a vital role. Designs incorporating external fins significantly increase the surface area available for natural convective heat transfer to the surrounding air. Utilizing materials with high thermal conductivity for critical housing sections helps draw heat away from internal components. Strategic placement of the drive unit to maximize exposure to ambient airflow aids cooling.

Forced Air Cooling: For applications consistently operating at the upper limits of the speed and load capacity, supplementary forced air cooling can be implemented. Directing airflow over the drive housing, particularly over finned areas, dramatically enhances convective heat dissipation rates, effectively lowering operating temperatures.

Thermal Interface Materials: Ensuring optimal thermal contact between high-heat-generating components (like the bearing raceways) and the housing structure is crucial. High-performance thermal interface materials can fill microscopic air gaps, significantly improving the conduction path for heat flow out of the drive core.

Implementing these methods in combination allows the SP-H 0855 to reliably achieve its rated high-speed performance without succumbing to thermal degradation of lubricants, premature wear, or loss of preload in the bearing assembly.

Characteristics of Heavy Duty Gear Slewing Drive SP-H 0855

The SP-H 0855 distinguishes itself through a suite of robust engineering features designed for maximum performance and durability under heavy loads and demanding conditions:

Exceptional Torque Capacity: Delivers a maximum drive torque (Md max) of 45,585 Nm and a maximum holding torque (Mh) of 45,585 Nm, providing immense rotational force and braking strength. Its nominal operating torque (Md nom) is a substantial 32,560 Nm.

Superior Load Handling: Engineered to withstand extreme forces, featuring an axial static load capacity (Co ax) of 2,570 KN and a radial static load capacity (Co rad) of 980 KN. Dynamic load ratings (Cax: 365 KN, Crad: 308 KN) ensure reliable performance under varying operational stresses.

High-Speed Capability: Rated for rotational speeds up to 15 RPM, catering to applications requiring faster slewing motions without sacrificing power or precision.

Robust Gear Design: Features an 8 mm module gear system with a high gear ratio of 8.2:1 (123 teeth on the internal gear ring, 15 teeth on the pinion), providing significant speed reduction and torque multiplication in a compact footprint.

Integrated and Sealed Unit: Employs a fully sealed design (IP65 protection rating), encapsulating the gears, bearings, and lubrication within the housing. This protects critical components from dust, moisture, and contaminants, drastically reducing maintenance needs and extending service life.

Precision Engineering: Manufactured to exacting tolerances, ensuring minimal backlash and smooth, precise rotation critical for accurate positioning in applications like automation and lifting.

Eliminated Gear Meshing Issues: The integrated design inherently solves the complex alignment and backlash adjustment challenges typically associated with mating separate pinions to large slewing bearings.

Optimized Weight: Weighing 289 kg, the design achieves an excellent strength-to-weight ratio, minimizing the structural burden on supporting frameworks while maximizing load capacity.

Drive Flexibility: Compatible with input from either hydraulic motors or electric motors, offering adaptability to various power sources within different machine designs.

Interchangeability: Designed as a direct replacement for IMO model SP-H 0855, simplifying upgrades or replacements.

Applications of Heavy Duty Gear Slewing Drive SP-H 0855

The combination of high torque, significant load capacity, precision, and robustness makes the SP-H 0855 indispensable across numerous heavy industrial sectors:

Crane Technology: The quintessential application, providing reliable 360-degree rotation for slew rings on mobile cranes (all-terrain, crawler, truck-mounted), tower cranes (slewing upper works), and heavy-duty jib cranes. Handles the massive overturning moments and axial loads inherent in lifting operations.

Heavy Machinery & Construction Equipment: Powers the rotation of excavator superstructures, drill rig platforms, large material handler booms, concrete pump booms, and stabilizer legs, where high torque and durability under shock loads are paramount.

Material Handling & Logistics: Used in heavy-duty rotators for scrap handling grapples, large container handling equipment, automated storage and retrieval systems (AS/RS), and port machinery requiring precise and powerful slewing motion.

Renewable Energy: Essential for the azimuth drives in large solar trackers, enabling precise sun-following movement under wind loads, and in positioning systems for wind turbine installation and maintenance equipment.

Industrial Automation & Robotics: Provides robust and precise rotational axes for heavy-duty robotic arms, turntables in welding cells, large positioners, automated assembly lines, and palletizing/depalletizing systems handling significant weights.

Mining & Mineral Processing: Powers rotary feeders, stackers, reclaimers, and large screening equipment operating in harsh, abrasive environments demanding maximum reliability.

Defense & Special Vehicles: Found in turret rotation systems for military vehicles and specialized transport platforms requiring robust, dependable slewing under demanding conditions.

Factors Influencing Heavy Duty Gear Slewing Drive SP-H 0855 Price

The investment in an SP-H 0855 slewing drive is significant, and its price reflects the sophisticated engineering and materials involved. Key factors determining cost include:

Material Costs & Specifications: The drive's performance hinges on using high-grade, often forged, alloy steels for gears, pinions, and bearing components. Fluctuations in global steel prices directly impact manufacturing costs. The specific alloys required for achieving the hardness, toughness, and fatigue resistance needed for the rated loads (e.g., 2,570 KN axial static) are a major cost driver.

Precision Manufacturing & Quality Control: Achieving the tight tolerances necessary for smooth operation, minimal backlash, and long life requires advanced CNC machining centers, specialized gear cutting and grinding equipment, and rigorous quality control processes throughout production (e.g., gear tooth profile inspection, hardness testing, dimensional checks). This level of precision manufacturing is inherently expensive.

Bearing Complexity & Integration: The heart of the slewing drive is its custom-designed, large-diameter slewing bearing capable of handling combined axial, radial, and moment loads simultaneously. Manufacturing these bearings to the specified static and dynamic load ratings (Co ax 2570 KN, Crad 308 KN, etc.) involves complex processes and high-quality bearing steel. The integration of this bearing seamlessly into the gear drive unit adds further engineering and assembly cost.

Sealing & Protection: Achieving the IP65 rating necessitates high-quality sealing systems (multiple lip seals, often with special elastomers) and meticulous housing design to ensure reliable exclusion of contaminants. These seals and the engineering behind them contribute to the cost.

Heat Treatment & Surface Engineering: Critical components undergo specialized heat treatment processes (like carburizing, hardening, and tempering) and often surface treatments (grinding, superfinishing, coatings like PVD) to achieve the required surface hardness, core toughness, wear resistance, and reduced friction. These processes are energy-intensive and require precise control.

Scale of Production & Customization: While the SP-H 0855 is a standard model, economies of scale apply. Larger production runs can reduce unit cost. Conversely, any customization (special mounting flanges, unique input shaft configurations, specific sealing requirements, special lubricants) adds cost.

Testing & Certification: Comprehensive load testing (often to exceed rated capacities) and potentially specific industry certifications add to the development and production overhead.

Supply Chain & Logistics: The cost of raw materials, components (seals, fasteners), energy, and transportation (especially given the unit's 289 kg weight) all factor into the final price.

Brand Value & Support: Reputable manufacturers like LYRADRIVE invest heavily in engineering expertise, application support, warranty, and after-sales service, which is reflected in the product value proposition.

Heavy Duty Gear Slewing Drive SP-H 0855 Supplier

LYRADRIVE stands as the original equipment manufacturer (OEM) and a leading global supplier of the Heavy Duty Gear Slewing Drive SP-H 0855. Leveraging extensive expertise in precision gear systems and slewing bearing technology, LYRADRIVE designs and manufactures the SP-H 0855 to exacting quality standards, ensuring it meets the demanding specifications outlined for torque, load capacity, speed, and environmental protection. The company provides comprehensive technical support, assisting customers with application engineering, selection, and integration. LYRADRIVE's commitment to robust design, reliable performance, and the IP65 sealed construction makes the SP-H 0855 a trusted solution for critical rotation applications worldwide. Furthermore, LYRADRIVE offers the SP-H 0855 as a direct interchangeable equivalent to the IMO model SP-H 0855. For sourcing this high-performance drive unit, consulting directly with LYRADRIVE ensures access to the genuine product and expert application guidance.